Blade vibration monitoring test device with continuously adjustable sensor installation angle

A technology for installation angle and vibration monitoring, which is applied in the field of high-speed rotating blade vibration measurement and real-time monitoring, and can solve problems such as the impact of monitoring accuracy and sensor failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

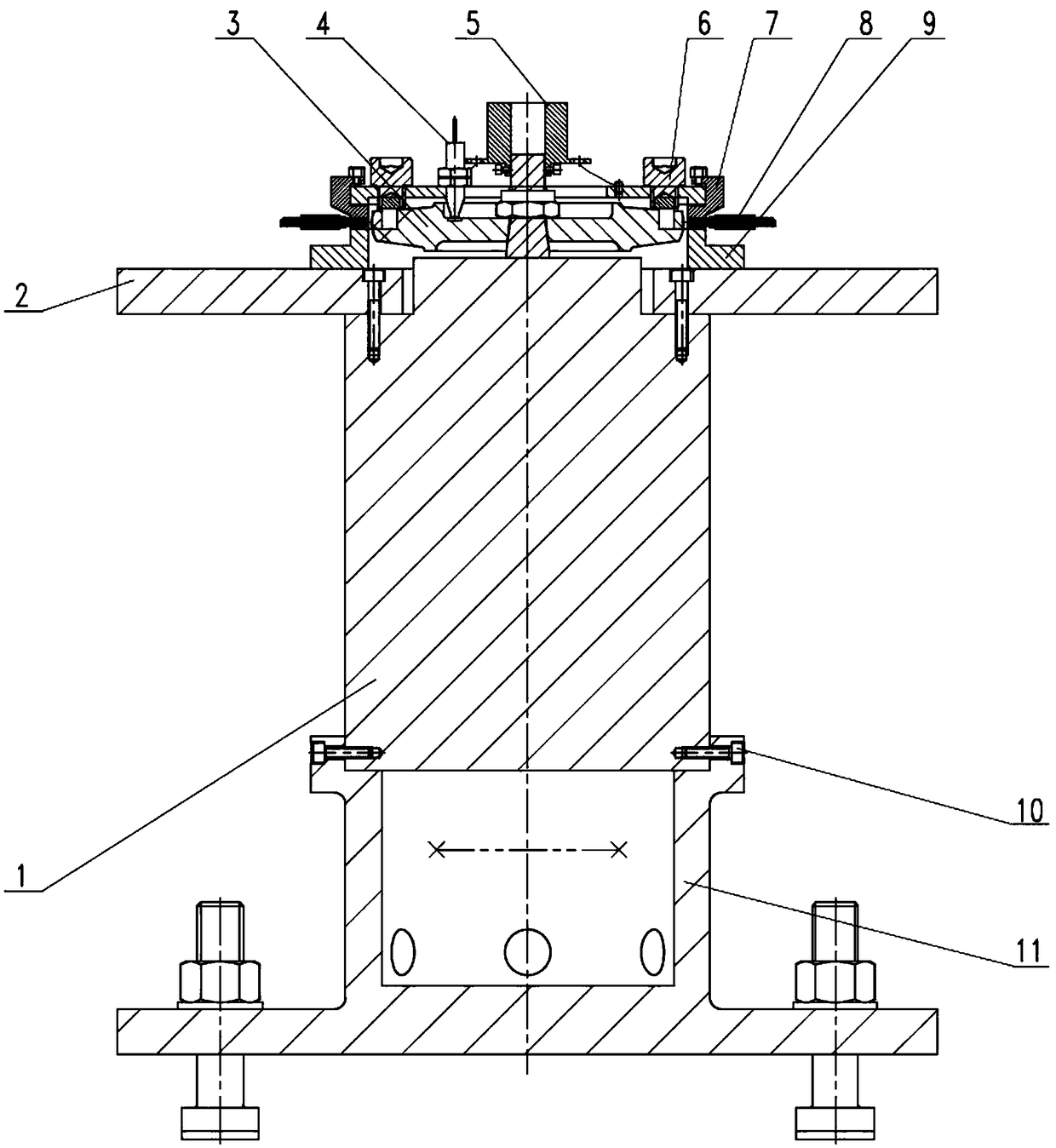

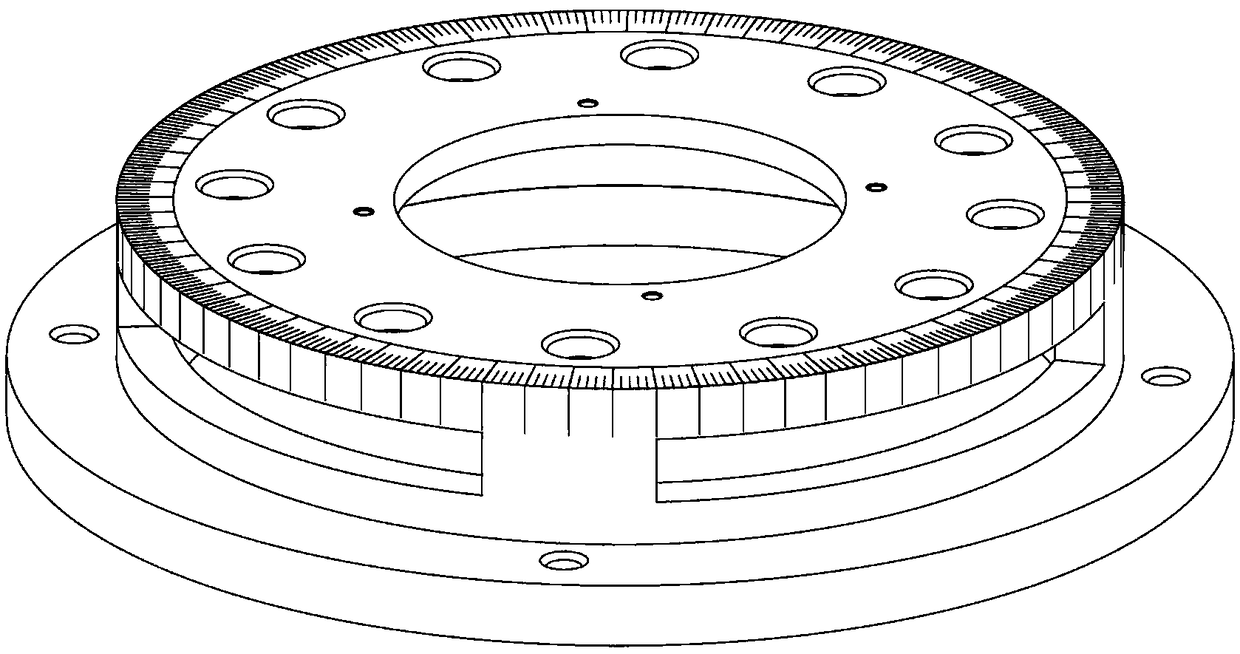

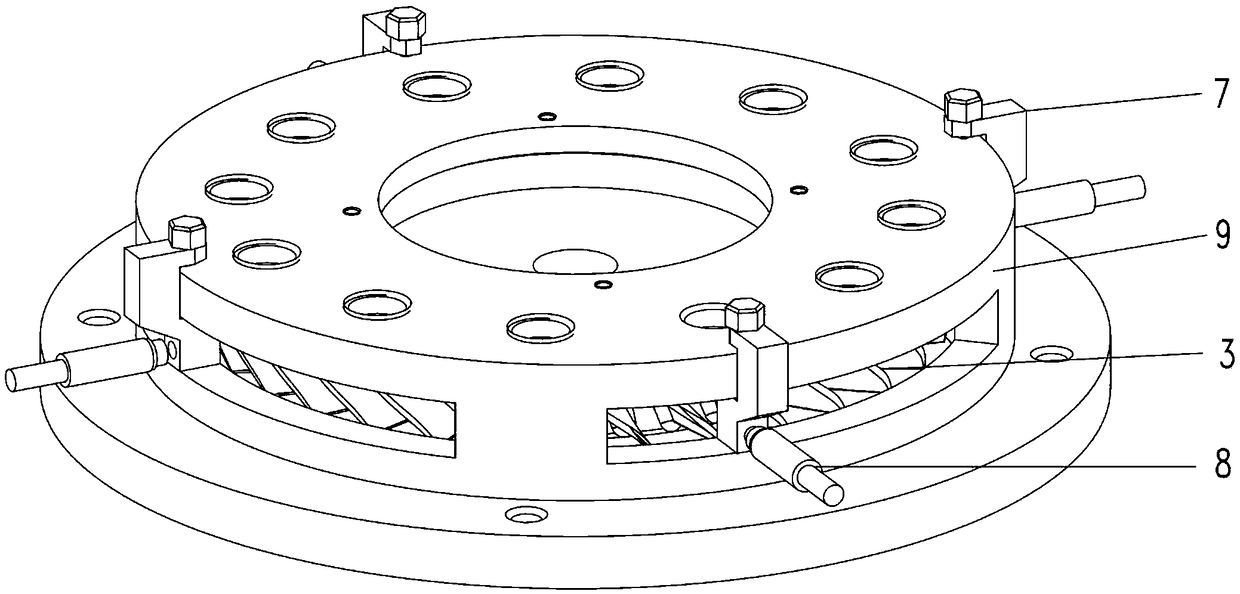

[0023] See attached figure 1 , the present invention consists of a high-speed motor 1, an operating platform 2, an impeller 3, a key phase sensor 4, a strain slip ring 5, an excitation device 6, a sensor bracket 7, a blade top sensor 8, an impeller shield 9, and a PT100 thermal resistance temperature sensor 10 And base 11 is formed.

[0024] The base 11 is fixed on the ground by bolts, the high-speed motor 1 is installed on the base 11, the operation platform 2 is fixed on the top end surface of the high-speed motor 1 by screws, the impeller 3 is installed on the main shaft of the high-speed motor 1, and the impeller guard 9 It is fixed on the operation platform 2 by screws; the key phase sensor 4 is fixed above the impeller 3 through the magnetic base, and the strain slip ring 5 is installed on the main shaft of the high-speed motor 1 above the impeller 3; the vibration excitation device 6 is installed on the impeller shield 9, the sensor bracket 7 is fixed on the edge of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com