Three-dimensional microwave component testing device

A technology for microwave components and testing devices, applied in the directions of measuring devices, coupling devices, test/measurement connectors, etc., can solve the problems of not mentioning three-dimensional microwave component testing, small vertical size, small volume, etc., to improve testing efficiency and Accuracy, Resolving Test Efficiency and Testing Complex Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

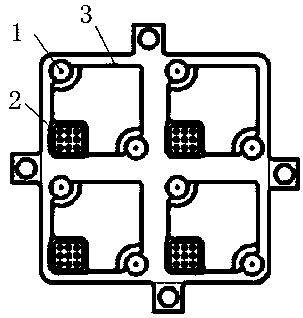

[0025] As an embodiment of the present invention, at least two high-frequency connectors and or at least two high-frequency connectors are fixedly arranged on the metal frame 3 .

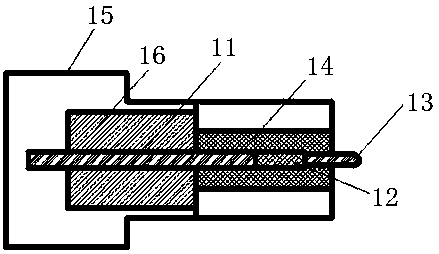

[0026] As a further improvement and embodiment of the scheme of the present invention, such as image 3 As shown, it also includes a first insulating support material 14, which is fixedly arranged in the second part of the metal casing 15, wrapped around the other part of the metal needle 11 of the A1 section, the first conductive elastic member 12 and the B1 section metal needle 13 The part located in the metal shell, on the one hand, plays a supporting role for the other part of the metal needle 11 of the A1 section, the first conductive elastic member 12 and the metal needle 13 of the B1 section, and on the other hand ensures that the other part of the metal needle 11 of the A1 section, The first conductive elastic member 12 and the B1 segment metal 13 are not in contact with the metal shell 15 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com