Processing method based on multifunctional processing device for touch film

A processing device and processing method technology, applied in the direction of printing device, data processing input/output process, instrument, etc., can solve the problems of waste of manpower and material resources, high production cost, expensive price, etc., to avoid disconnection, ensure accuracy and quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

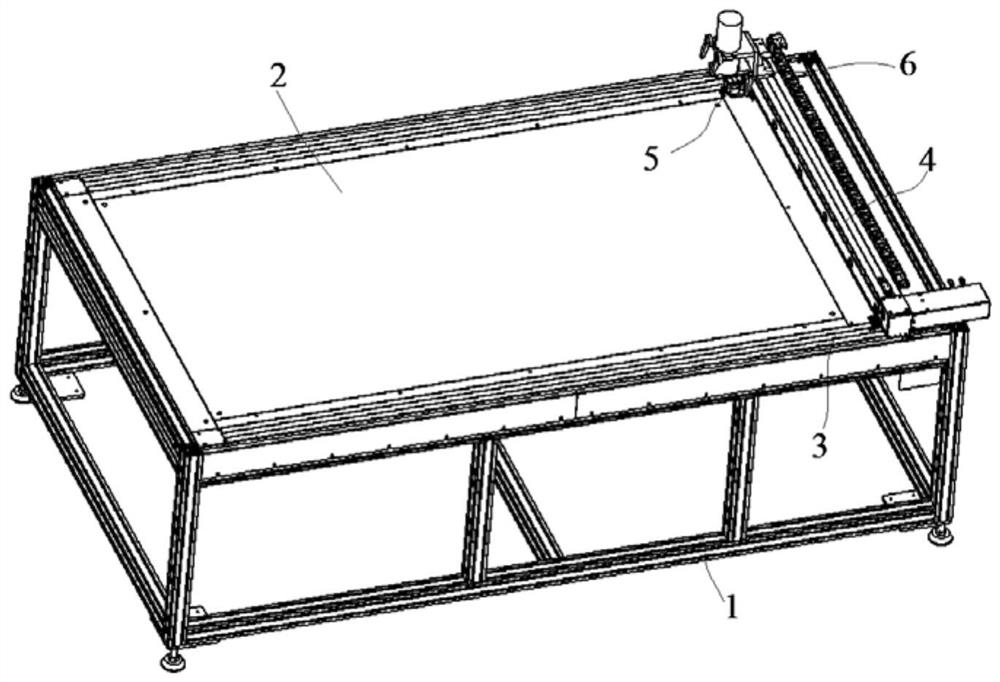

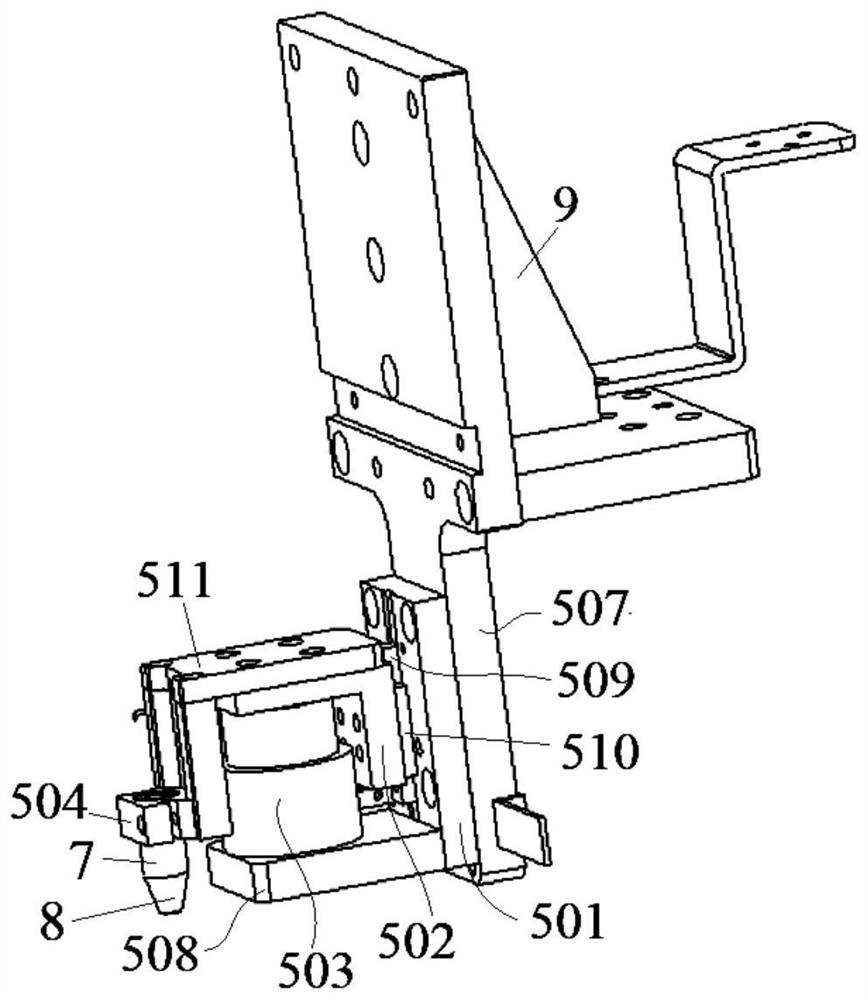

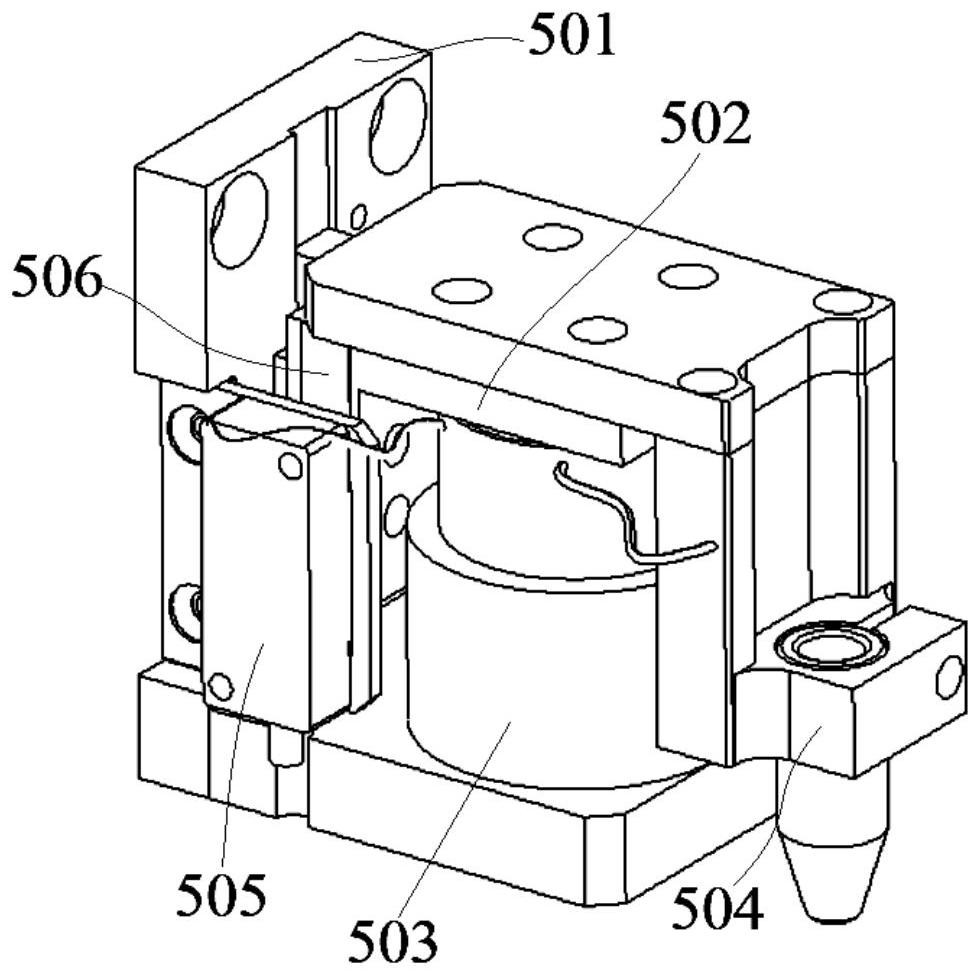

[0044] Embodiment 1: A processing method based on a multifunctional processing device for a touch film, the processing method is based on a multifunctional processing device for a touch film, and the multifunctional processing device for a touch film includes Frame 1, working panel 2, X-axis driving mechanism 3, Y-axis driving mechanism 4 and Z-axis mechanism 5, the working panel 2 is horizontally installed on the frame 1, and the X-axis driving mechanism 3 is installed on the frame 1 Above, the Y-axis drive mechanism 4 is movably installed on the X-axis drive mechanism 3, and the Z-axis mechanism 5 is movably connected with the Y-axis drive mechanism 4 through a mounting plate 6. The Z-axis mechanism 5 has a test state and Processing state, when the Z-axis mechanism 5 is in the testing state, a test head 7 is movably installed on the Z-axis mechanism 5, and a printing head 7 is movably installed on the Z-axis mechanism 5 when the Z-axis mechanism 5 is in the processing state. ...

Embodiment 2

[0059]Embodiment 2: A processing method based on a multifunctional processing device for a touch film, the processing method is based on a multifunctional processing device for a touch film, and the multifunctional processing device for a touch film includes Frame 1, working panel 2, X-axis driving mechanism 3, Y-axis driving mechanism 4 and Z-axis mechanism 5, the working panel 2 is horizontally installed on the frame 1, and the X-axis driving mechanism 3 is installed on the frame 1 Above, the Y-axis drive mechanism 4 is movably installed on the X-axis drive mechanism 3, and the Z-axis mechanism 5 is movably connected with the Y-axis drive mechanism 4 through a mounting plate 6. The Z-axis mechanism 5 has a test state and Processing state, when the Z-axis mechanism 5 is in the testing state, a test head 7 is movably installed on the Z-axis mechanism 5, and a printing head 7 is movably installed on the Z-axis mechanism 5 when the Z-axis mechanism 5 is in the processing state. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com