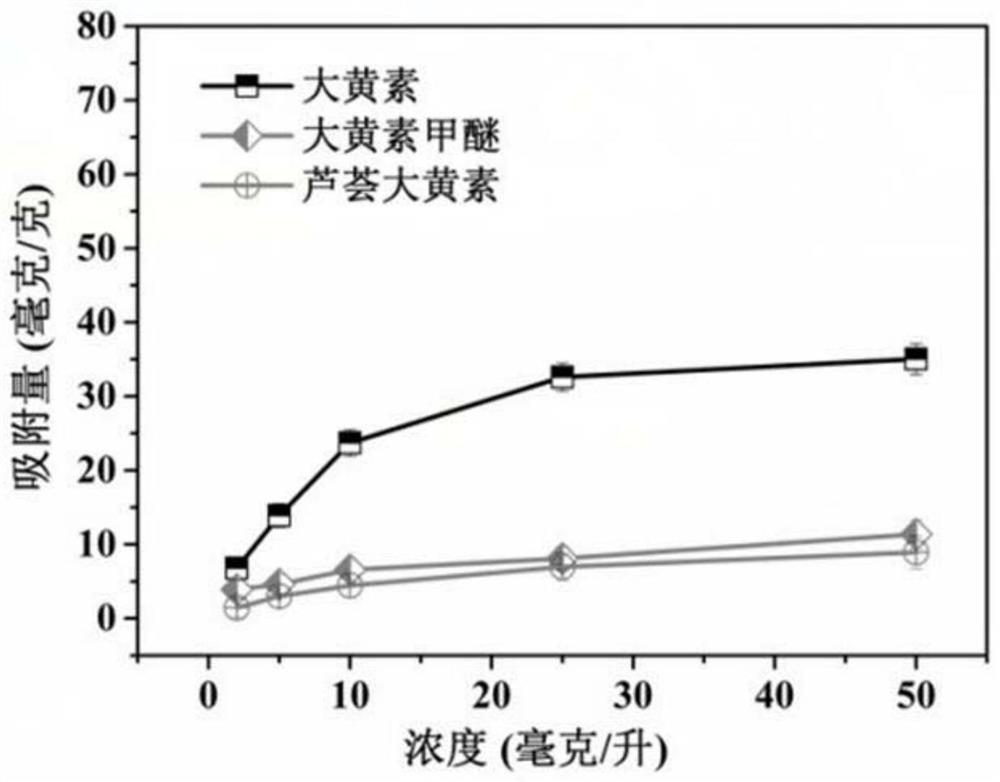

A kind of emodin molecularly imprinted silica nanoparticle composite film and its preparation method and application

A silicon dioxide and nanoparticle technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of low flow rate and low flow rate of molecularly imprinted membrane, and achieve difficult recovery, high flow rate, and smooth flow rate. high volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Preparation of tetraethyl orthosilicate modified cellulose acetate membrane:

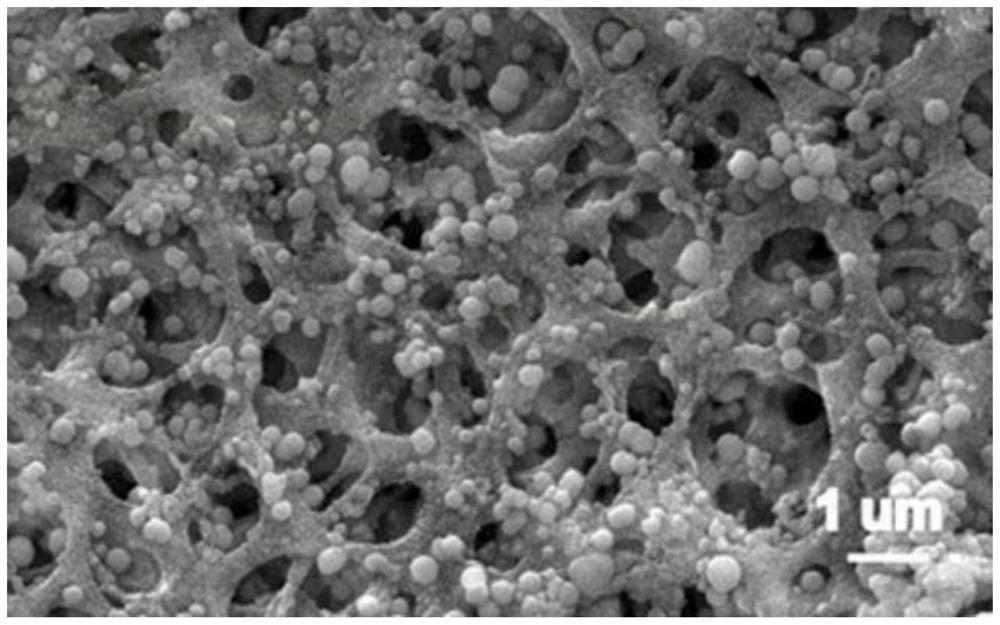

[0044] Submerge 3 pieces of commercially available cellulose acetate membranes (47mm×0.135mm) into a mixed solution consisting of 100mL deionized water, 30mL ethanol and 1mL tetraethyl orthosilicate, shake for 5min, slowly add 0.5mL ammonia water dropwise, and ultrasonically Evenly, vibrate in an oscillator for 6 hours, seal, soak in deionized water, wash and dry to obtain a silica-modified cellulose acetate film; figure 1 As shown, the silica-modified cellulose acetate membrane was coated with a polymer layer of uniform thickness.

[0045] (2) Preparation of emodin molecularly imprinted silica nanoparticle composite film:

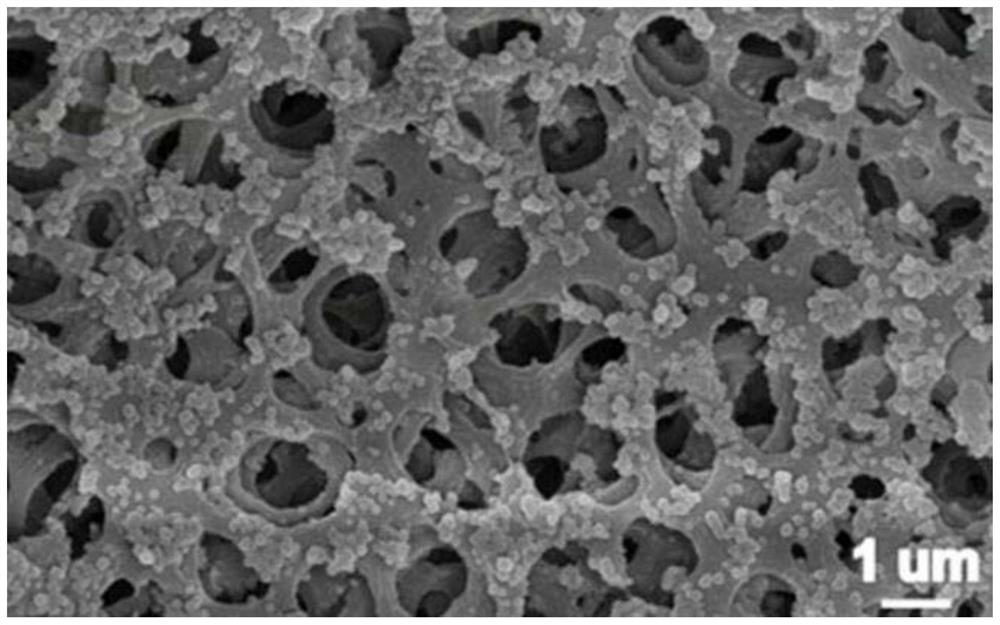

[0046] After ultrasonically mixing 0.1211g of Tris and 100mL of water, adjust the pH value to 8.5, and add 3 pieces of silica-modified cellulose acetate membrane obtained in the above step (1) to achieve the purpose of purification; Add the purified membrane to a mi...

Embodiment 2

[0050] (1) Preparation of tetraethyl orthosilicate modified cellulose acetate membrane

[0051] Submerge 3 pieces of commercially available cellulose acetate membranes (47mm×0.135mm) into a mixed solution consisting of 100mL deionized water, 30mL ethanol and 1mL tetraethyl orthosilicate, shake for 5min to complete the reaction, and slowly drop 0.5mL Ammonia, ultrasonically uniform, oscillating in an oscillator for 6 hours, sealing, washing with deionized water after soaking, and drying to obtain a silica-modified cellulose acetate membrane.

[0052] (2) Preparation of emodin molecularly imprinted silica nanoparticles composite film

[0053] After ultrasonically mixing 0.1211g of Tris and 100mL of water, adjust the pH value to 8.5, and add 3 pieces of silica-modified cellulose acetate membrane obtained in the above step (1) to achieve the purpose of purification; Add the purified membrane to a mixture of 0.025g emodin, 100mL water and 0.1211g trishydroxymethylaminomethane, ult...

Embodiment 3

[0057] (1) Preparation of tetraethyl orthosilicate modified cellulose acetate membrane

[0058] Submerge 3 pieces of commercially available cellulose acetate membranes (47mm×0.135mm) into a mixed solution consisting of 100mL deionized water, 30mL ethanol and 1mL tetraethyl orthosilicate, shake for 5min, slowly add 0.5mL ammonia water dropwise, and ultrasonically Evenly, oscillate in an oscillator for 6 hours, seal, wash with deionized water after soaking, and dry to obtain a silica-modified cellulose acetate film;

[0059] (2) Preparation of emodin molecularly imprinted silica nanoparticles composite film

[0060] After ultrasonically mixing 0.1211g of Tris and 100mL of water, adjust the pH value to 8.5, and add 3 pieces of silica-modified cellulose acetate membrane obtained in the above step (1) to achieve the purpose of purification; Add the purified membrane to a mixture composed of 0.1g emodin, 100mL water and 0.1211g trishydroxymethylaminomethane, ultrasonically uniform,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com