A kind of emodin molecularly imprinted titanium dioxide nanoparticle composite film and its preparation method and application

A technology of titanium dioxide and molecular imprinting, which is applied to chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problems of small flow rate and low flow rate of molecular imprinted membranes, and solve the problem of difficult recovery and low flow rate. Large, high-throughput effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Preparation of titanium dioxide modified cellulose acetate membrane

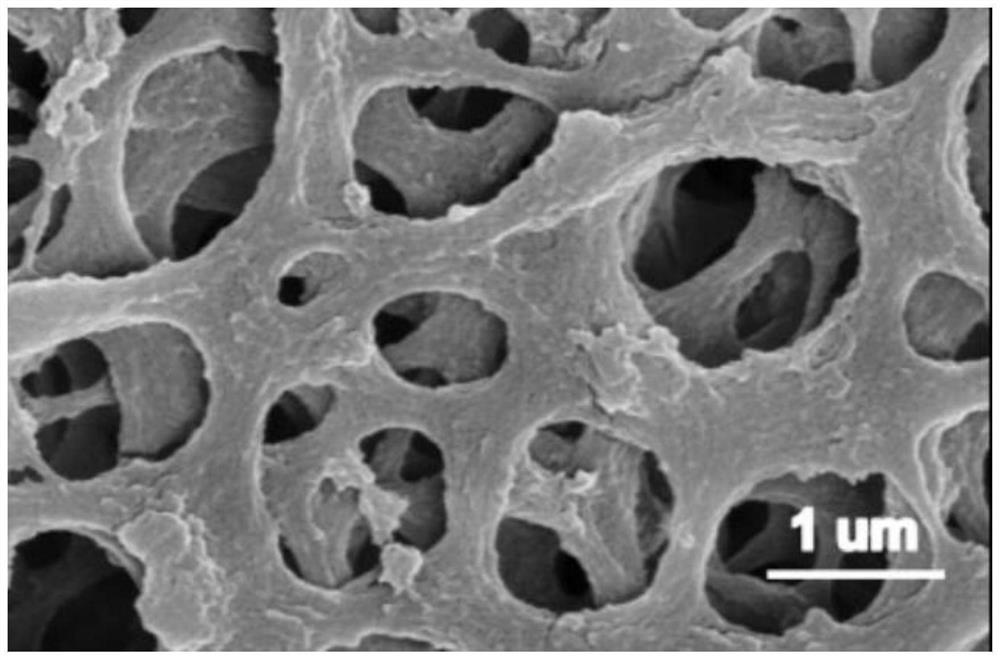

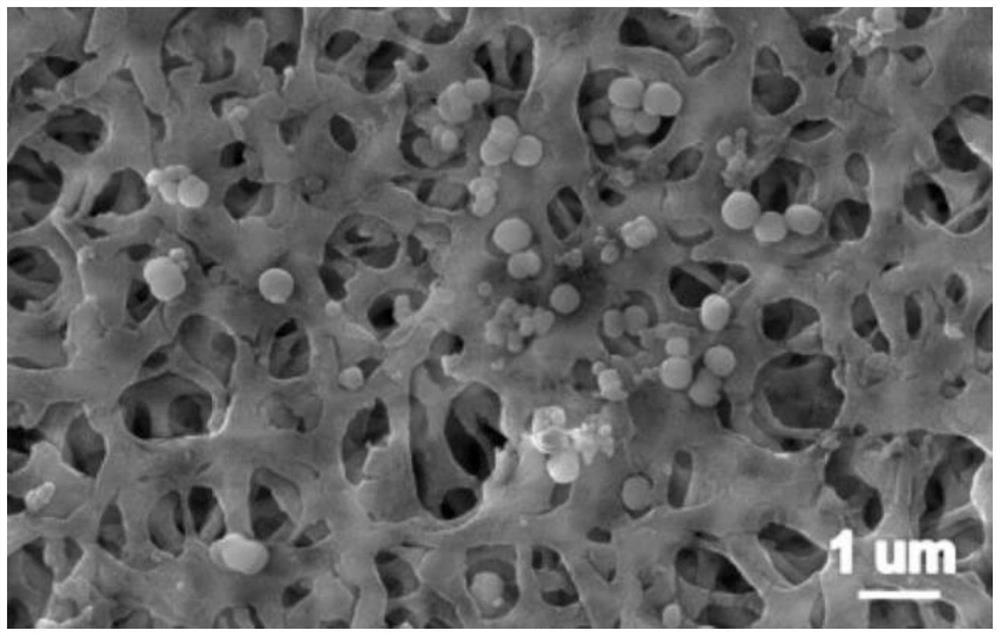

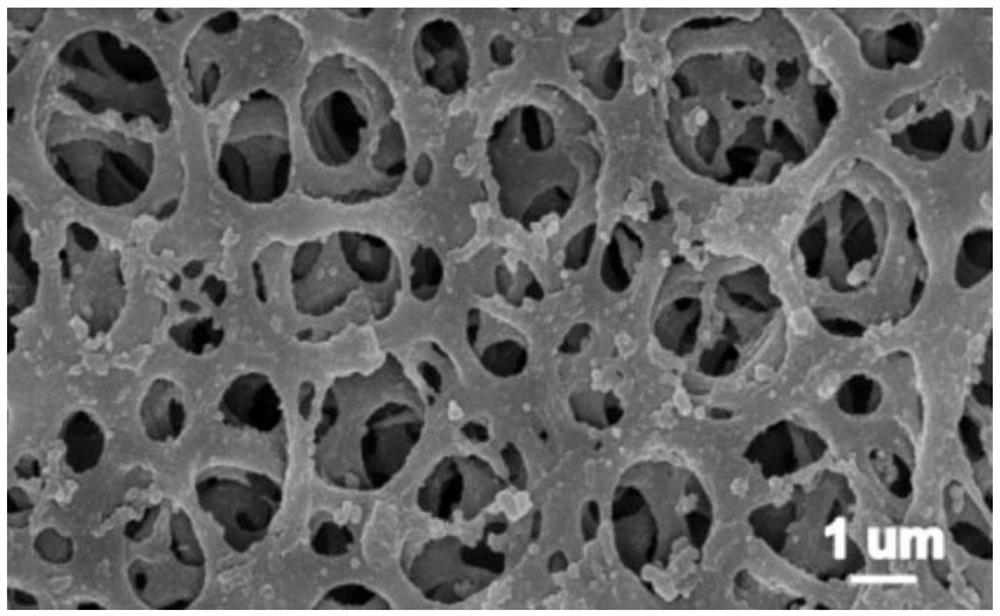

[0050] Add 0.03moL of boric acid and 1.8549g of ammonium fluotitanate to 100mL of deionized water, ultrasonically homogenize, adjust the pH value to 3.86 after hydrolysis for 1 hour, add purified cellulose acetate membrane, seal and vibrate in a shaker for 2 hours, soak with deionized After washing with water and drying at 40°C, a titanium dioxide-modified cellulose acetate film was obtained; figure 1 , figure 2 It can be observed that the purified cellulose acetate membrane after titanium dioxide modification is coated with a polymer layer of uniform thickness.

[0051] (2) Preparation of emodin molecularly imprinted titanium dioxide nanoparticle composite film

[0052] After ultrasonically mixing the mixture of 0.1211g tris and 100mL water, adjust the pH value to 8.5, and add 3 pieces of titanium dioxide-modified cellulose acetate membrane obtained in the above step (1) to achieve the purpose...

Embodiment 2

[0056] (1) Preparation of titanium dioxide modified cellulose acetate membrane

[0057] Add 0.03moL boric acid and 1.8549g ammonium fluotitanate to 100mL deionized water, ultrasonically homogenize, hydrolyze for 0.5h, adjust the pH value to 3.86, add purified cellulose acetate membrane, vibrate in a shaker for 1h, seal, and use after soaking After cleaning with deionized water and drying, titanium dioxide modified cellulose acetate film is obtained;

[0058] (2) Preparation of emodin molecularly imprinted titanium dioxide nanoparticle composite film

[0059] After ultrasonically mixing the mixed solution of 0.1211g of trishydroxymethylaminomethane and water, adjust the pH value to 8.5, and add 3 pieces of titanium dioxide-modified cellulose acetate membranes obtained in the above step (1) to achieve the purpose of purification; Add the purified titanium dioxide-modified cellulose acetate membrane to an aqueous solution composed of 0.025g emodin, 100mL water and 0.1211g trishy...

Embodiment 3

[0064] (1) Preparation of titanium dioxide modified cellulose acetate membrane

[0065] Add 0.03moL boric acid and 1.8549g ammonium fluotitanate to 100mL deionized water, ultrasonically homogenize, hydrolyze for 2 hours, adjust the pH value to 3.86, add purified cellulose acetate membrane, vibrate in a shaker for 1 hour, seal it, and use it after soaking After washing with deionized water and drying, titanium dioxide modified cellulose acetate film is obtained;

[0066] (2) Preparation of emodin molecularly imprinted titanium dioxide nanoparticle composite film

[0067] After ultrasonically mixing the mixture of 0.1211g of Tris and water, adjust the pH value to 8.5, add 3 pieces of TiO obtained in the above step (1) 2 Modified cellulose acetate membrane to achieve the purpose of purification; the purified TiO 2 Add the modified cellulose acetate membrane to an aqueous solution composed of 0.1g emodin, 100mL water and 0.1211g trishydroxymethylaminomethane, ultrasonically unif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com