A cleaning and lifting device and method for a grain conveyor

A cleaning device and conveyor technology, used in chemical instruments and methods, wet separation, solid separation, etc., can solve problems such as single conveying function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

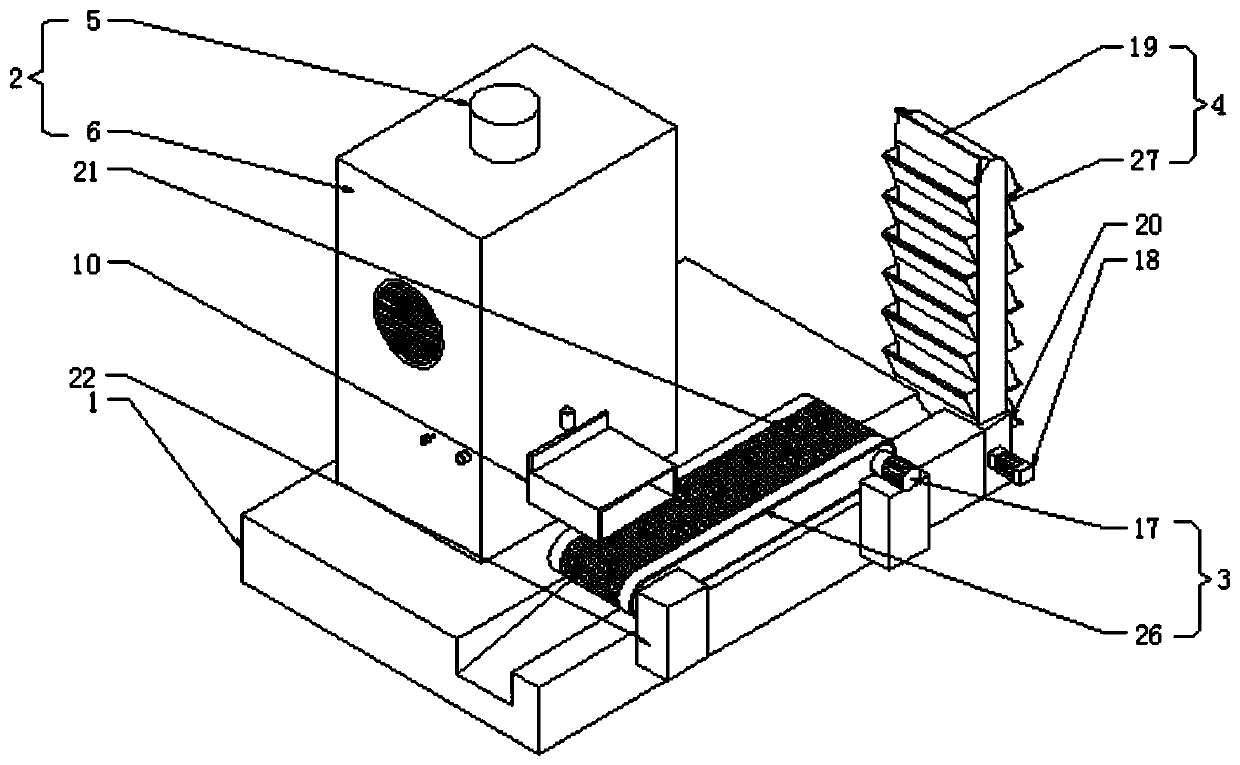

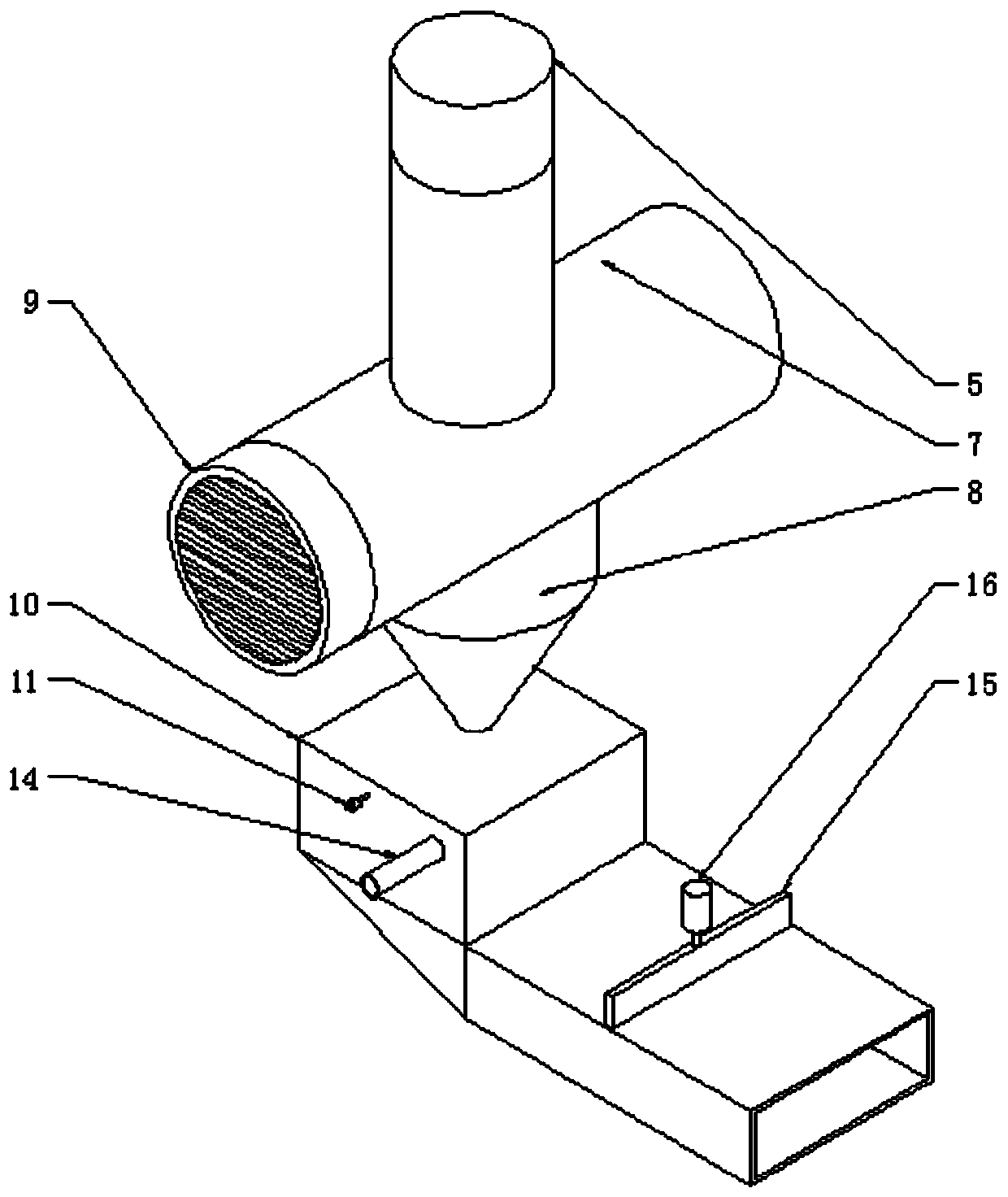

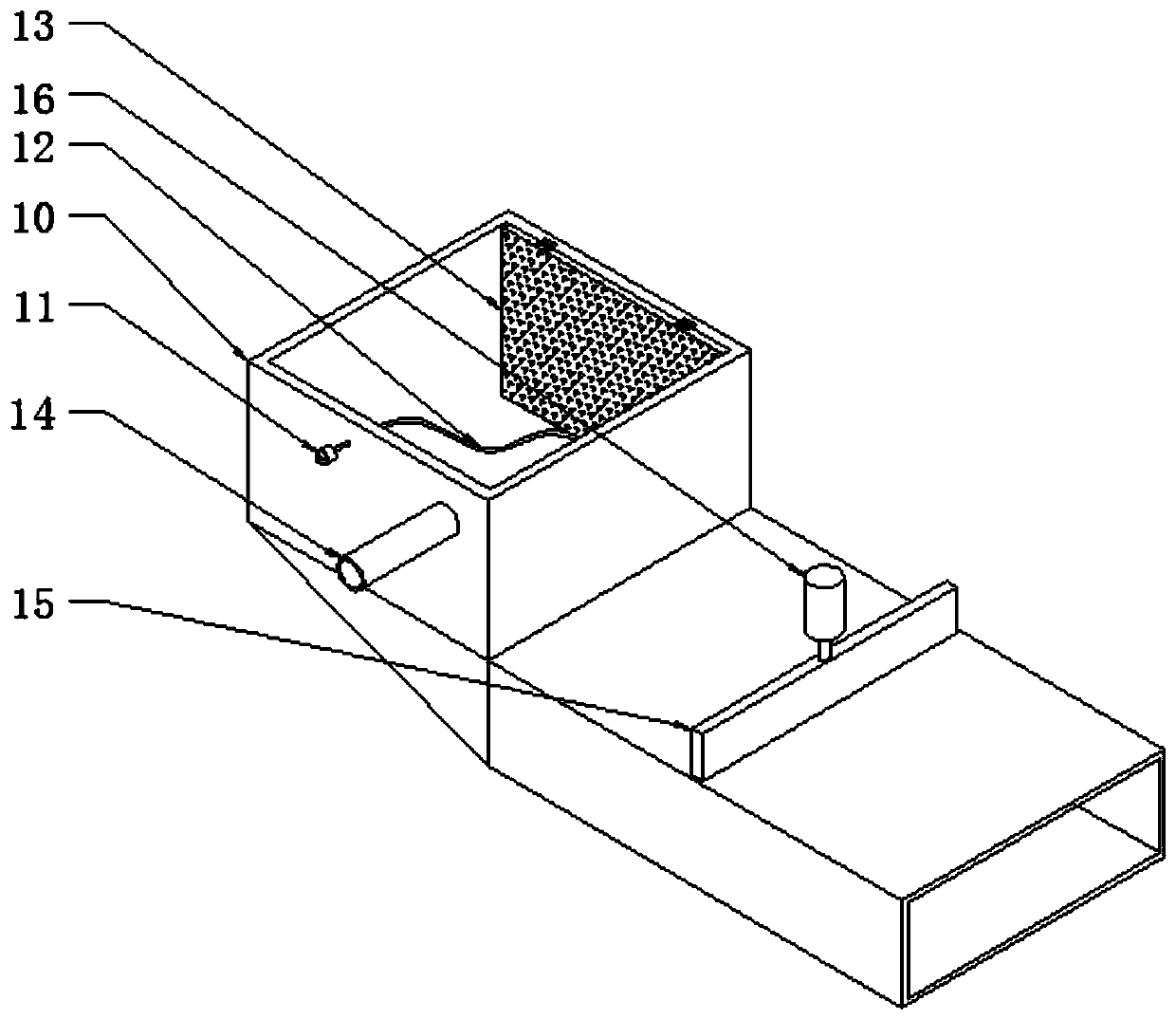

[0026] Example: such as Figure 1-6As shown, the cleaning and lifting device and method of a grain conveyor of the present invention include a base 1, a cleaning device 2, a transmission device 3 and a lifting device 4, and the top on one side of the base 1 is fixedly connected to the bottom of the cleaning device 2 , the top of the other side of the base 1 is provided with a conveying device 3, the side of the base 1 is provided with a lifting device 4, the cleaning device 2 is composed of a casing 6 and a feeding pipe 5, and the top of the feeding pipe 5 is exposed from the casing 6 The top wall of the top wall, the bottom end of the feed pipe 5 is fixedly connected to the top of the wind box 7, and the two ends of the wind box 7 pass through the two outer walls of the shell 6 to contact with the outside air, and one end of the wind box 7 is fixedly provided with The first fan 9, the bottom of the miscellaneous wind box 7 is fixedly connected with the top of the material rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com