Variable camber wing trailing edge based on compliant mechanism

A compliant mechanism and trailing edge technology, applied in the field of the trailing edge of aircraft wings, can solve the problems of difficult implementation and complex structure, and achieve the effects of light weight, easy maintenance, and fewer components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

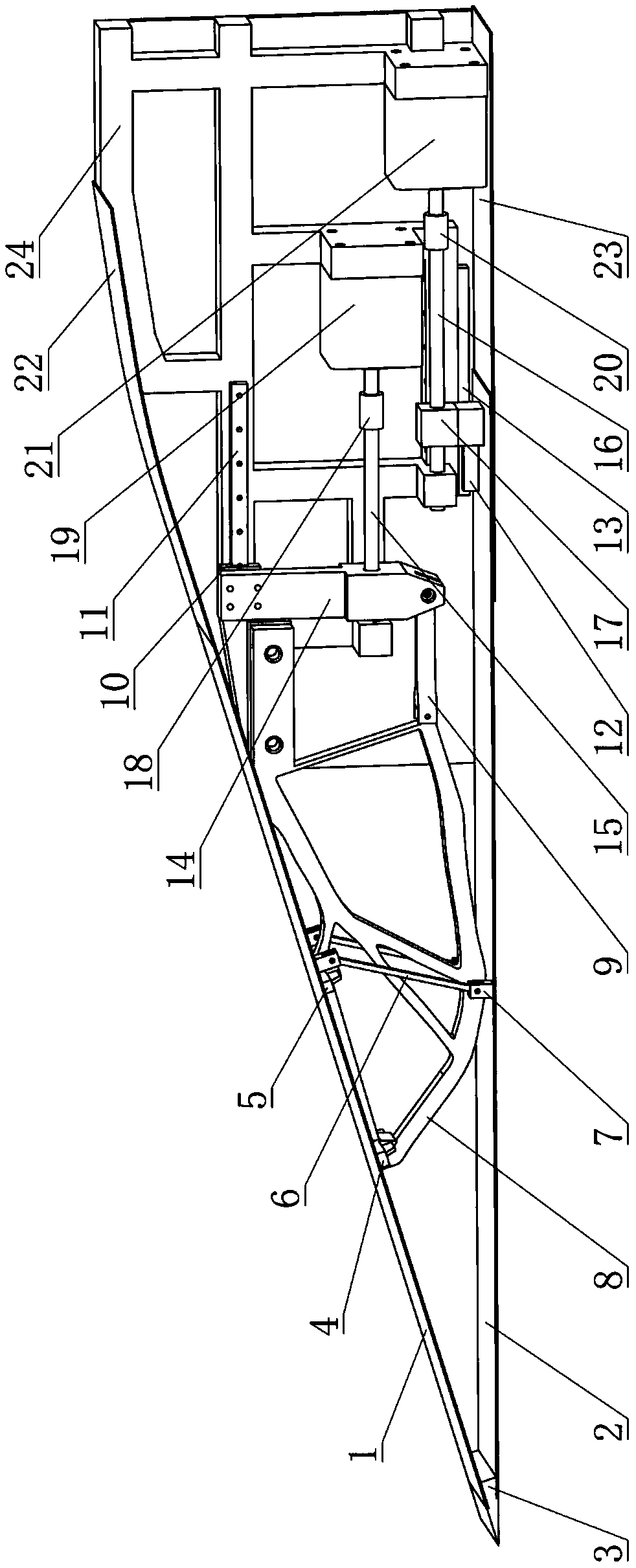

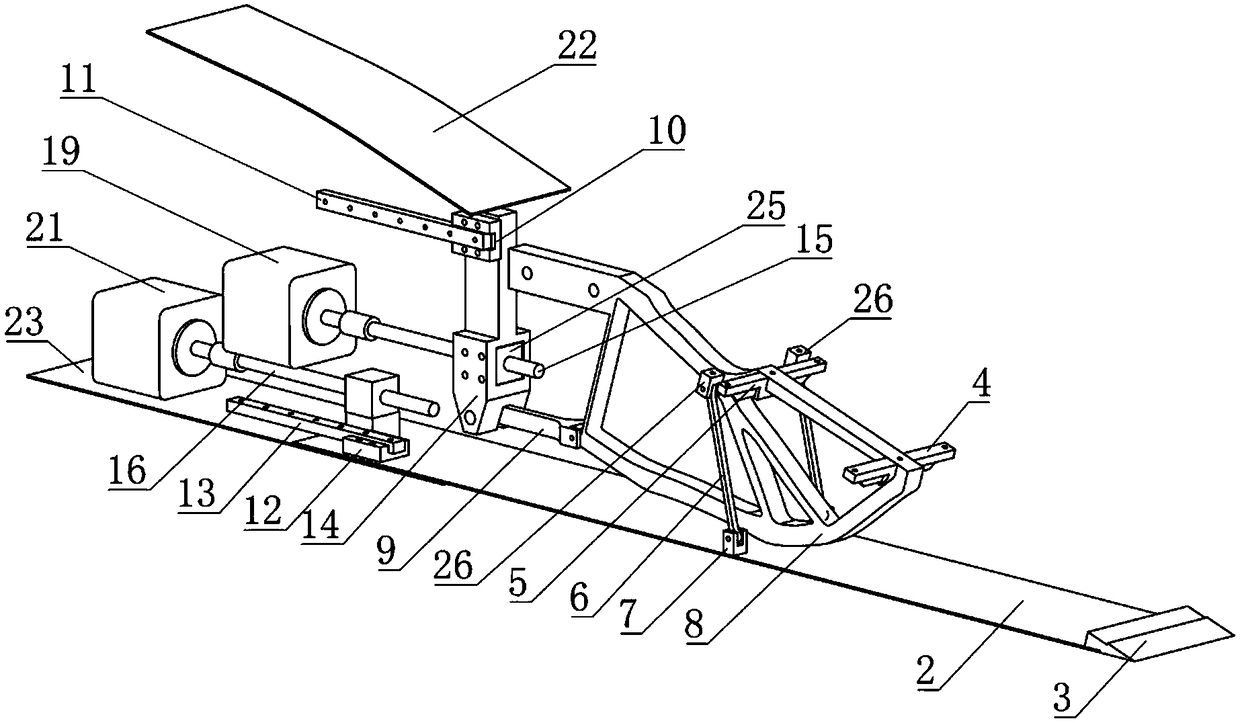

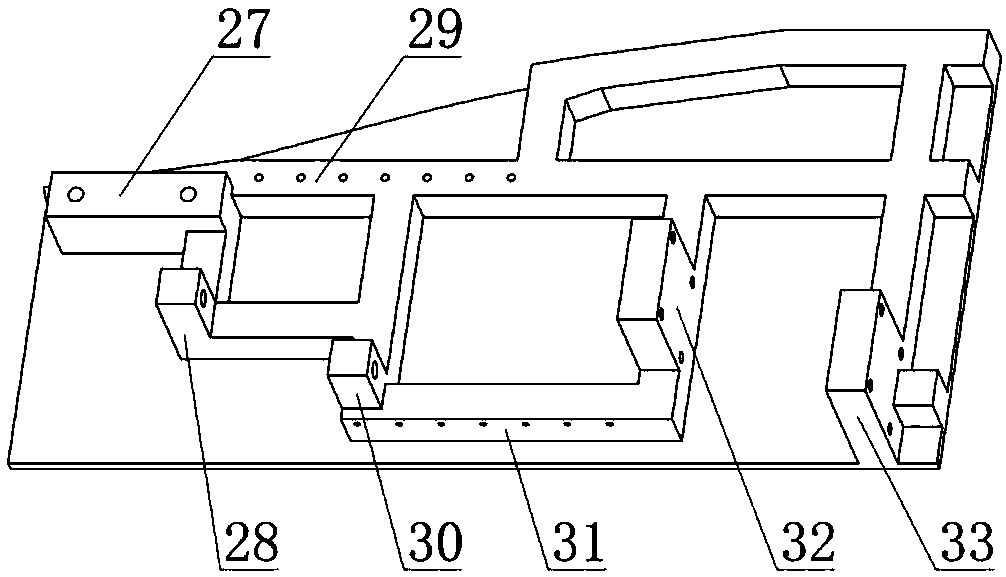

[0016] The present invention will now be further described in conjunction with the embodiments and drawings:

[0017] The present invention proposes a device that can continuously and smoothly change the camber of an aircraft wing with a trailing edge, the trailing edge is fixed at the rear end of the wing and has elastic upper and lower trailing edge skins. The upper skin of the trailing edge is fixed to the upper skin of the wing, and the lower skin of the trailing edge can be retracted into the lower skin of the wing. The upper and lower surface skins are connected by a compliant drive mechanism, and a link mechanism is added between two points where the distance between the upper and lower skins of the wing does not change before and after the rear edge of the wing is deformed to constrain the shape of the wing during the deformation process. Driven by the drive motor 1, the device acts on the trailing edge skin through a flexible mechanism to drive the trailing edge upper sk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com