Drainage control device for washing machine and washing machine

A technology of a control device and a washing machine, applied in the field of washing machines, can solve the problems of secondary pollution of clothes, long drainage time, wear and tear, etc., and achieve the effects of saving water, good sewage discharge effect, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

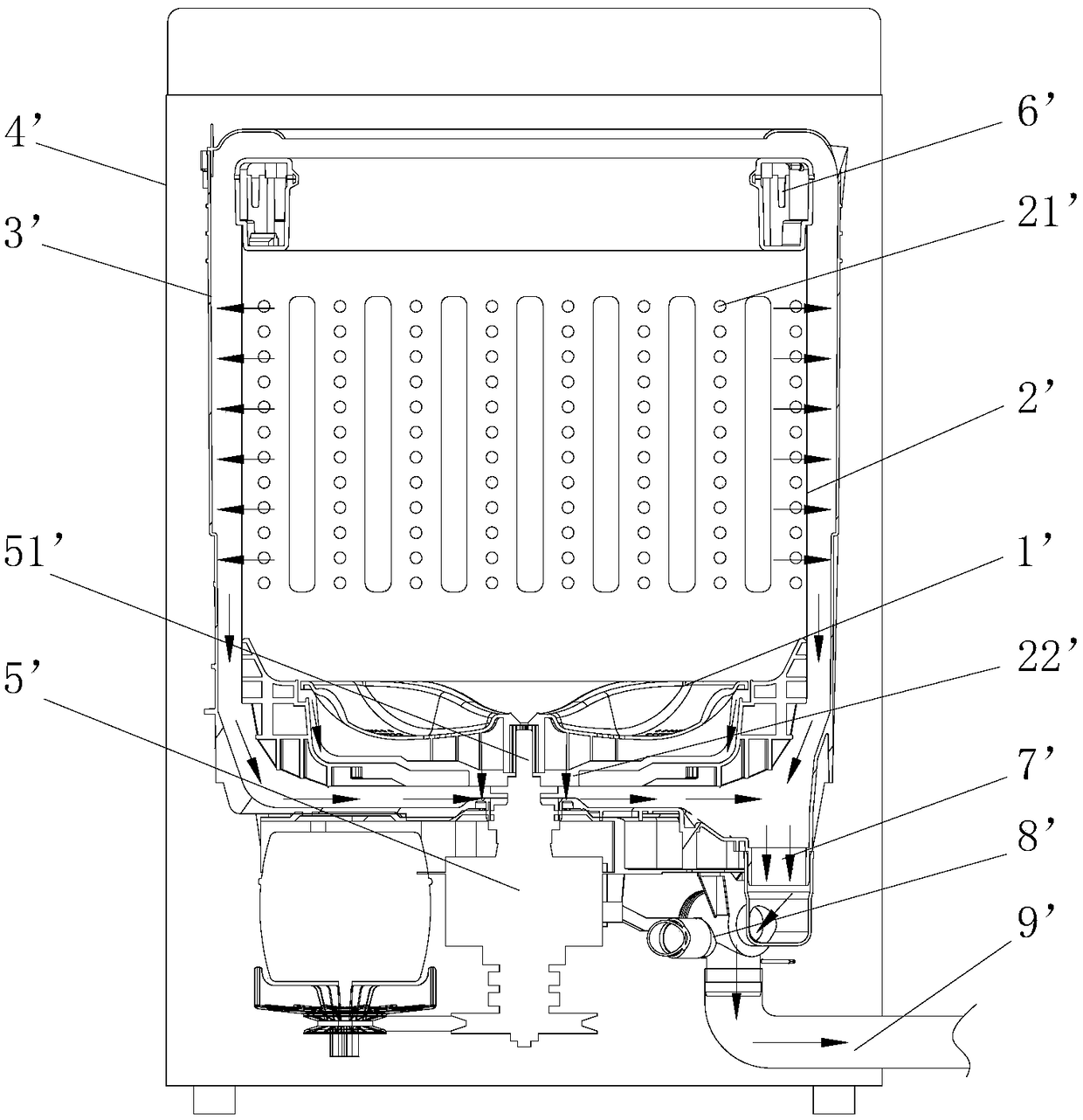

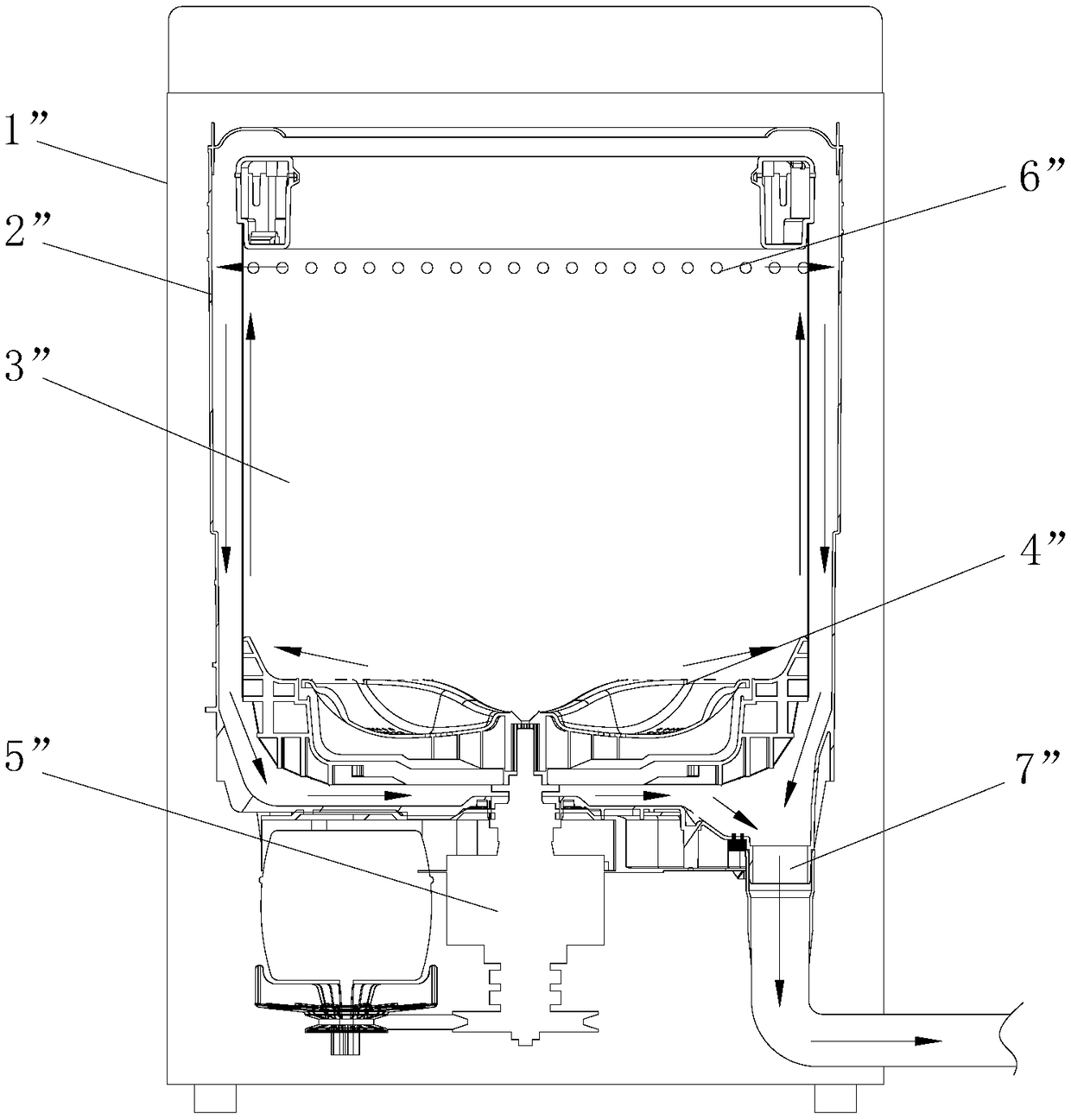

[0037] Such as Figure 4 As shown, the second drain hole 5 in this embodiment is provided at the bottom of the inner tub 2, and a sealing valve 6 is provided on the bottom of the outer tub 1 below the second drain hole 5, including a second drain hole that can be moved up and down to close / open the corresponding The valve plug 61 and the driving device 62 that drives the valve plug 61 to move up and down, the sealing valve 6 is installed at the bottom of the outer barrel and is sealed with the bottom of the outer barrel 1. When the valve plug 61 seals the second drain hole 5, according to the structure of the valve plug 61 and the structure of the second drain hole 5, end face sealing or circumferential sealing can be adopted.

[0038] In order to enable the sealing valve 6 to accurately close the second drainage hole 5, the second drainage hole 5 on the inner tub 2 must be accurately positioned above the sealing valve 6. Therefore, the washing machine is provided with an inner tu...

Embodiment 2

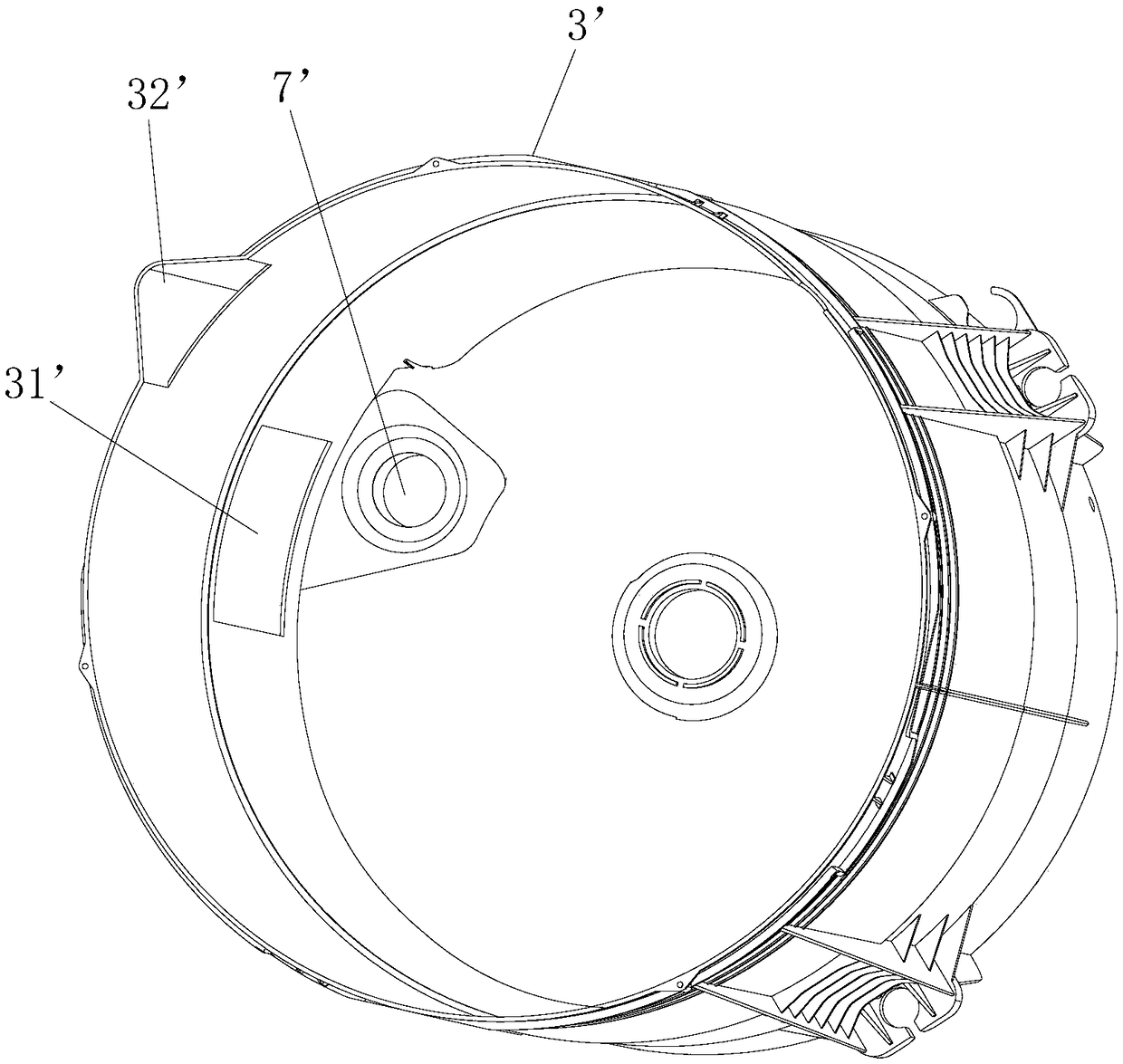

[0041] This embodiment is a further improvement of the first embodiment: Figure 5 As shown, in order to make the sealing valve 6 move upward and better match the sealing of the second drain hole 5, the second drain hole 5 is provided with a valve plug guide structure 8. The valve plug guide structure 8 is a bell mouth structure with a gradually larger diameter formed by the downward flanging of the second drain hole.

[0042] With this structure, when the valve plug 61 seals the second drain hole 5, the valve plug 61 cooperates with the valve plug guide structure 8 to form a circumferential seal. If the second drain hole 5 does not have a valve plug guide structure, in order to seal the second drain hole 5, the valve plug can adopt a larger sealing end surface.

Embodiment 3

[0044] Such as Figure 4 with 5 As shown, on the basis of the above two embodiments, this embodiment further defines: due to the processing or assembling of the outer barrel, the bottom of the outer barrel 1 may be tilted, and the movement direction of the sealing valve 6 is not perpendicular to the plane of the second drain hole 5 The valve plug 61 has a certain range of movement, and adjusts its angle automatically during the upward movement to cooperate with the second drain hole 5 to achieve accurate sealing.

[0045] Specifically, the valve plug has an inclination such that the lower end is a support point and the upper end is free to swing around (not shown in the figure).

[0046] Or like Picture 9 with 10 As shown, the valve plug 61 includes a plug head 611 and a valve stem 612, and the plug head 611 is movably connected with the valve stem 612, so that the plug head 611 is movable and finely adjusted at the position of the second drain hole 5. The end of the valve stem 61...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com