Connecting piece for steel structure building

A technology for steel structures and connectors, applied in construction, building construction, etc., can solve the problems of inability to have multiple sizes of steel structures, narrow application scope, weightlessness and instability, etc., to increase awareness danger or reaction time, and eliminate The effect of block tensile shear force failure and increasing flexibility and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

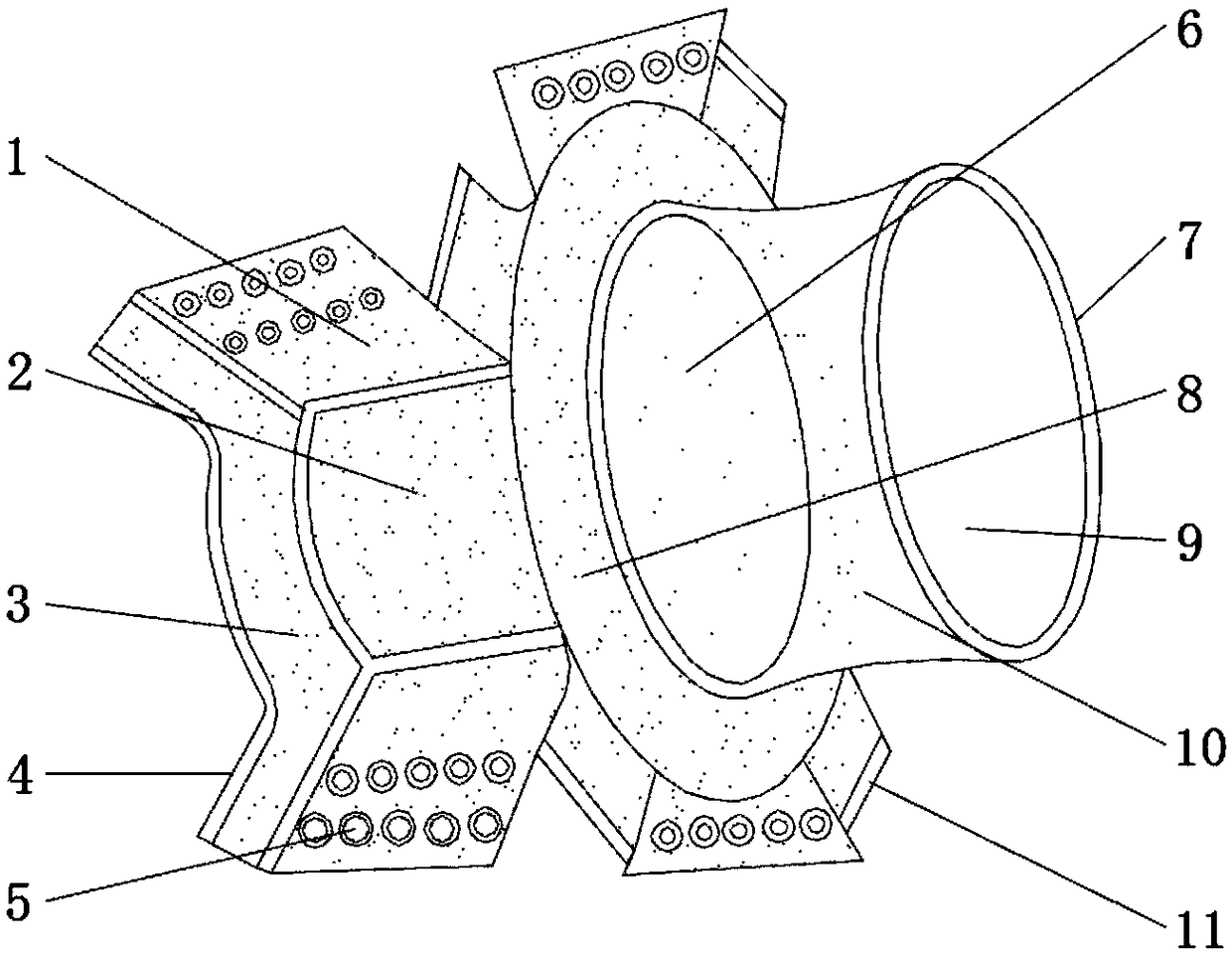

[0016] see figure 1 , as shown in the embodiment in the accompanying drawings: both ends of the connecting plate 1 are welded with wrapping wings 4, and the wrapping wings 4 can form a fixed area suitable for fixing circular steel columns with the arc-shaped fixing area 3, and the connecting plate 1 is arranged symmetrically on both sides of the arc-shaped fixing area 3 to form a rectangular fixing area 2. The arc-shaped fixing area 3 extends arc-shaped to both ends and then tilts upward to form a wrapping wing 4. Therefore, the rectangular fixing area 2 is an open connection port, and the column The end of the shaped steel can be directly fixed and docked with the rectangular fixing area 2, and then the connecting plate 1 is fixed and covered on the upper and lower ends of the column shaped steel, and the side ends are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com