Handling method for mining quality accident

A kind of accident handling and quality technology, applied in ground mining, mining equipment, underground mining, etc., can solve the problems of failure to reach the upper section, poor blasting effect, high mining loss rate, etc., achieve reasonable matching of blasting parameters, and improve mining recovery The best effect of rate and blasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

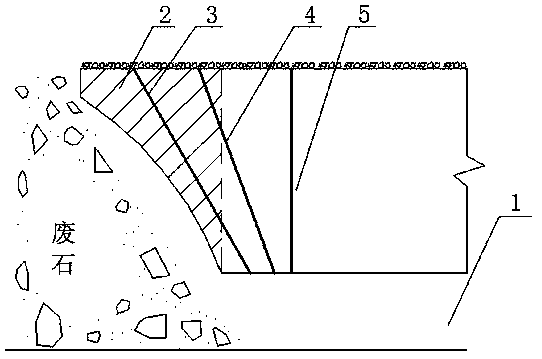

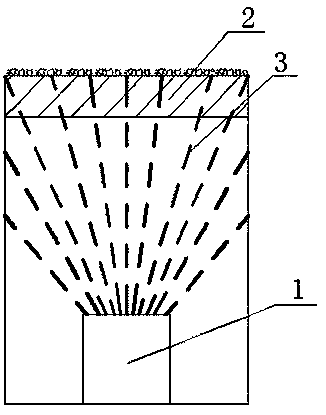

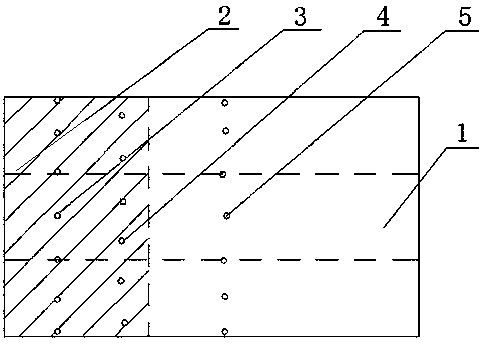

[0027] Such as Figure 1 to Figure 3 A kind of mining quality accident processing method is shown, the first row of medium-deep holes 3, the second row of medium-deep holes 4, and the third row of medium-deep holes 5 are sequentially set on the inside of the top rock formation accident area 2 of the mining roadway 1, and each row The medium-deep holes are arranged in a fan shape to form a fan-shaped medium-deep hole. The face angle of the first row of 3 rows of medium-deep holes is 60°, the face angle of the second row of 4 rows of medium-deep holes is 70°, and the third row of 5 rows of medium-deep holes The angle is 90°, and the fan-shaped middle and deep holes should meet the following requirements: the side hole angle is 50°, the hole depth is 6 meters, the diameter of the middle and deep holes is 60 mm, and the row spacing w of the middle and deep holes in adjacent rows is 0.3 meters. The bottom distance a of the deep holes in the row is 13d, and the density factor is 2. ...

Embodiment 2

[0030] Such as Figure 1 to Figure 3 A kind of mining quality accident treatment method shown, in the top stratum of mining roadway 1, the first row of deep holes 3, the second row of middle and deep holes 4, the third row of middle and deep holes 5 are arranged successively, and the middle and deep holes of each row are in the form of The fan-shaped arrangement forms fan-shaped medium-deep holes. The face angle of the first row of 3 rows of medium-deep holes is 60°, the face angle of the second row of 4 rows of medium-deep holes is 70°, and the face angle of the third row of 5 rows of medium-deep holes is 90°. , the fan-shaped middle and deep holes should meet the following requirements: the side hole angle is 60°, the hole depth is 9 meters, the diameter of the middle and deep holes is 65 mm, the row distance w of the middle and deep holes in adjacent rows is 0.4 meters, and the middle and deep holes in the same row The hole bottom distance a is 19d, and the density factor i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com