Double clutch

A dual-clutch and clutch body technology, applied in the field of clutches, can solve problems such as the inability to arbitrarily increase the motion output shaft, the use of torque, the lack of installation space, the increase in cost and the use of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

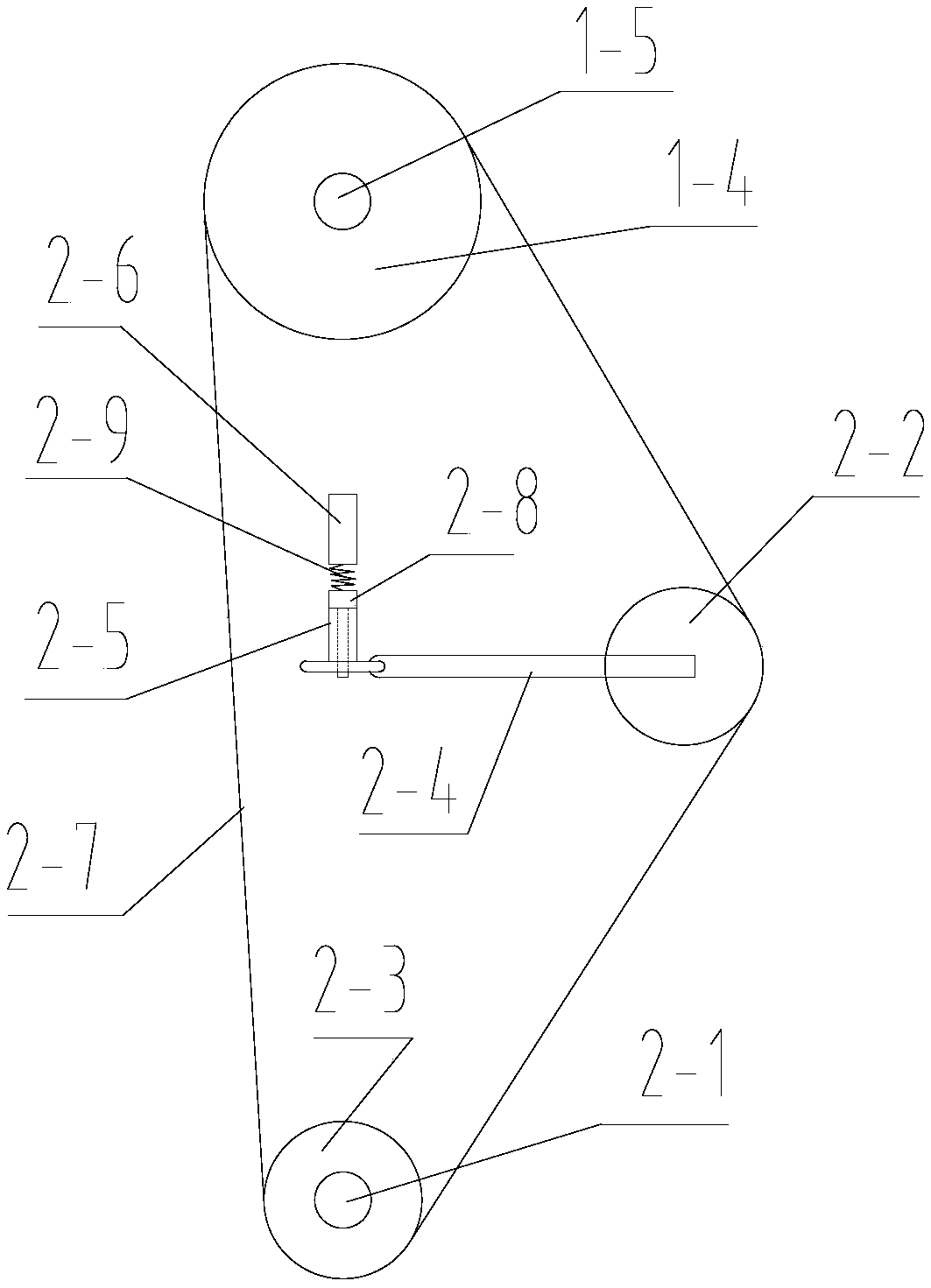

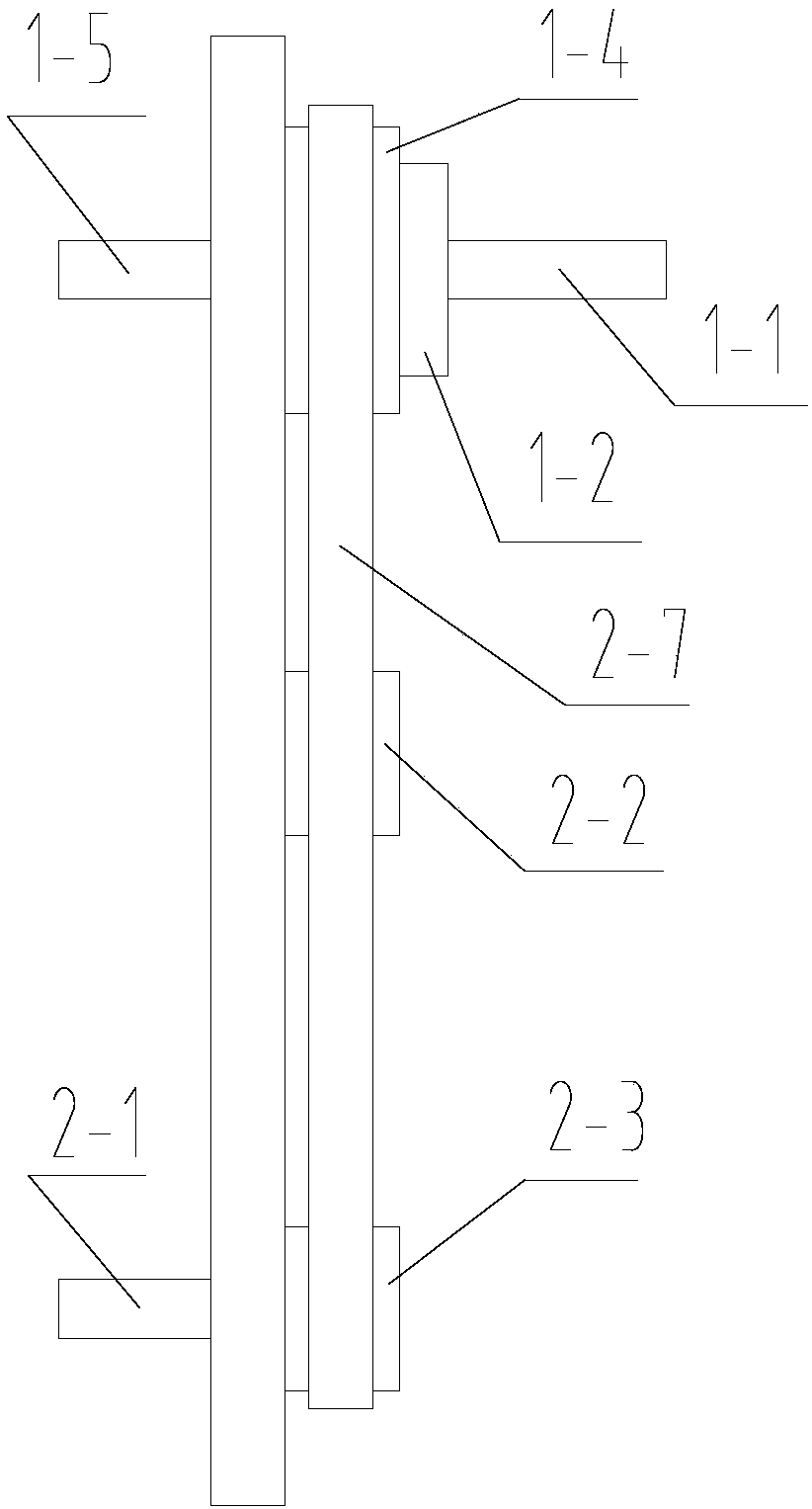

Image

Examples

Embodiment 1

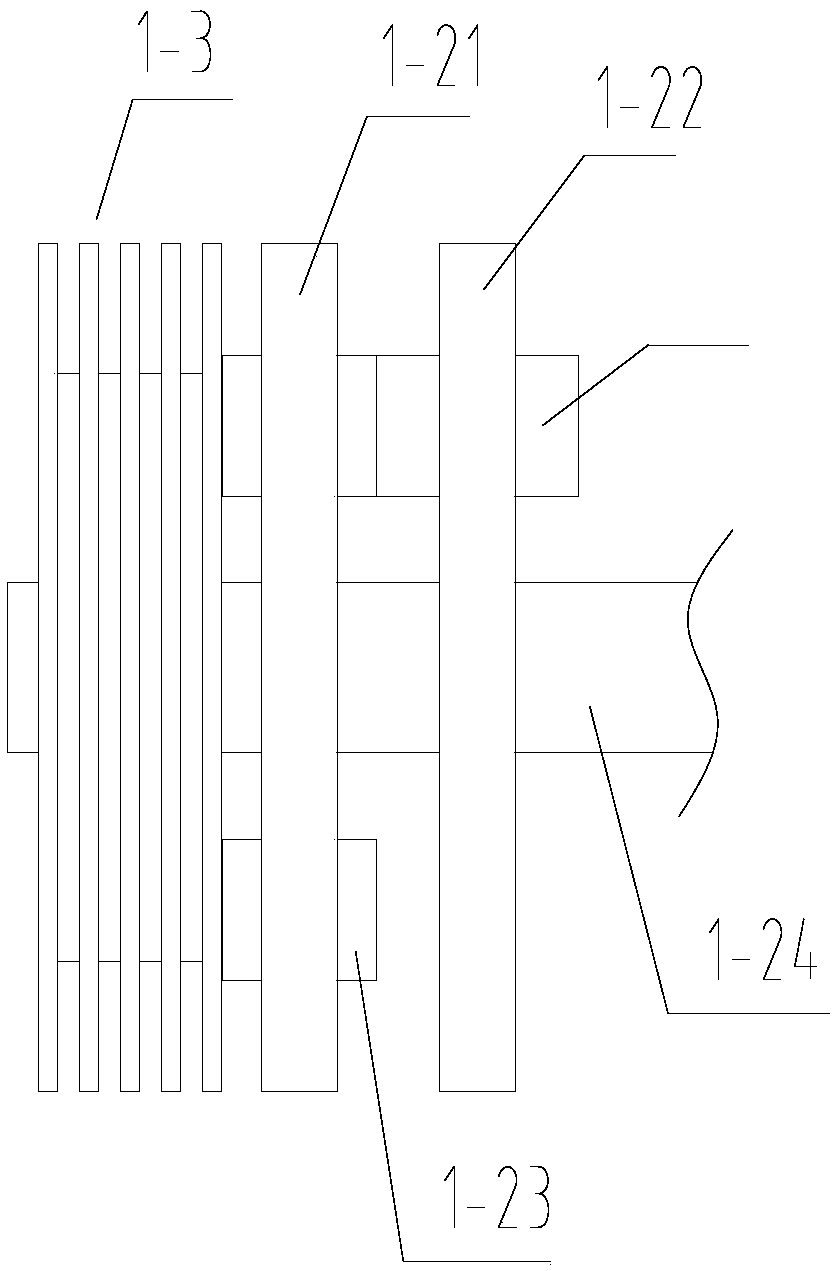

[0030]In this embodiment, the pressure plate 1-2 is composed of a moving plate 1-21 and a fixed plate 1-22, the moving plate 1-21 is set on the input shaft 1-1 in a linear motion, and the fixed plate 1-22 is set on the The input shaft 1-1 rotates following the input shaft 1-1. That is, the fixed disk 1-22 is fixedly connected or splined with the input shaft 1-1, and the fixed disk 1-22 is relatively stationary relative to the input shaft 1-1 in the axial direction. The moving plate 1-21 is provided with a plurality of first through holes distributed on the concentric circles of the moving plate 1-21. The fixed plate 1-22 is provided with at least one second through hole, and the second through hole is located on a circle whose axis coincides with the axis of the fixed plate 1-22 and whose radius is equal to the radius of the circle where the first through holes are located. A first gear 1-23 is rotatably installed in each first through hole, and the rotating shaft of the firs...

Embodiment 2

[0032] In this embodiment, the pressure plate 1-2 includes a first disc 1-2A, a second disc 1-2B and a third disc 1-2C which are sequentially sleeved on the input shaft 1-1. The second disc 1-2B is connected to the input shaft 1-1, and the second disc 1-2B is provided with at least one shaft that runs through the second disc 1-2B and whose axis coincides with the radial direction of the second disc 1-2B. Turn gear 1-2D. The first disc 1-2A is fixedly installed, the third disc 1-2C is rotatably installed and connected with the smooth surface of the input shaft 1-1, and the side of the first disc 1-2A facing the second disc 1-2B is provided with An annular tooth portion 1-2E meshing with the rotating gear 1-2D and located concentrically on the first disc 1-2A. The side of the third disk 1-2C facing the second disk 1-2B is provided with a fan-shaped tooth portion 1-2F meshed with the rotating gear 1-2D, and the fan-shaped tooth portion 1-2F passes through the third disk 1-2C Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap