Self-filled elbow, pipeline conveying system and concrete pump

A pipeline transportation and filling technology, applied in pipeline protection, pipe/pipe joints/fittings, and pipeline damage/wear prevention, etc., can solve problems such as rapid wear and tear, reduce use costs, improve wear resistance, and achieve longevity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

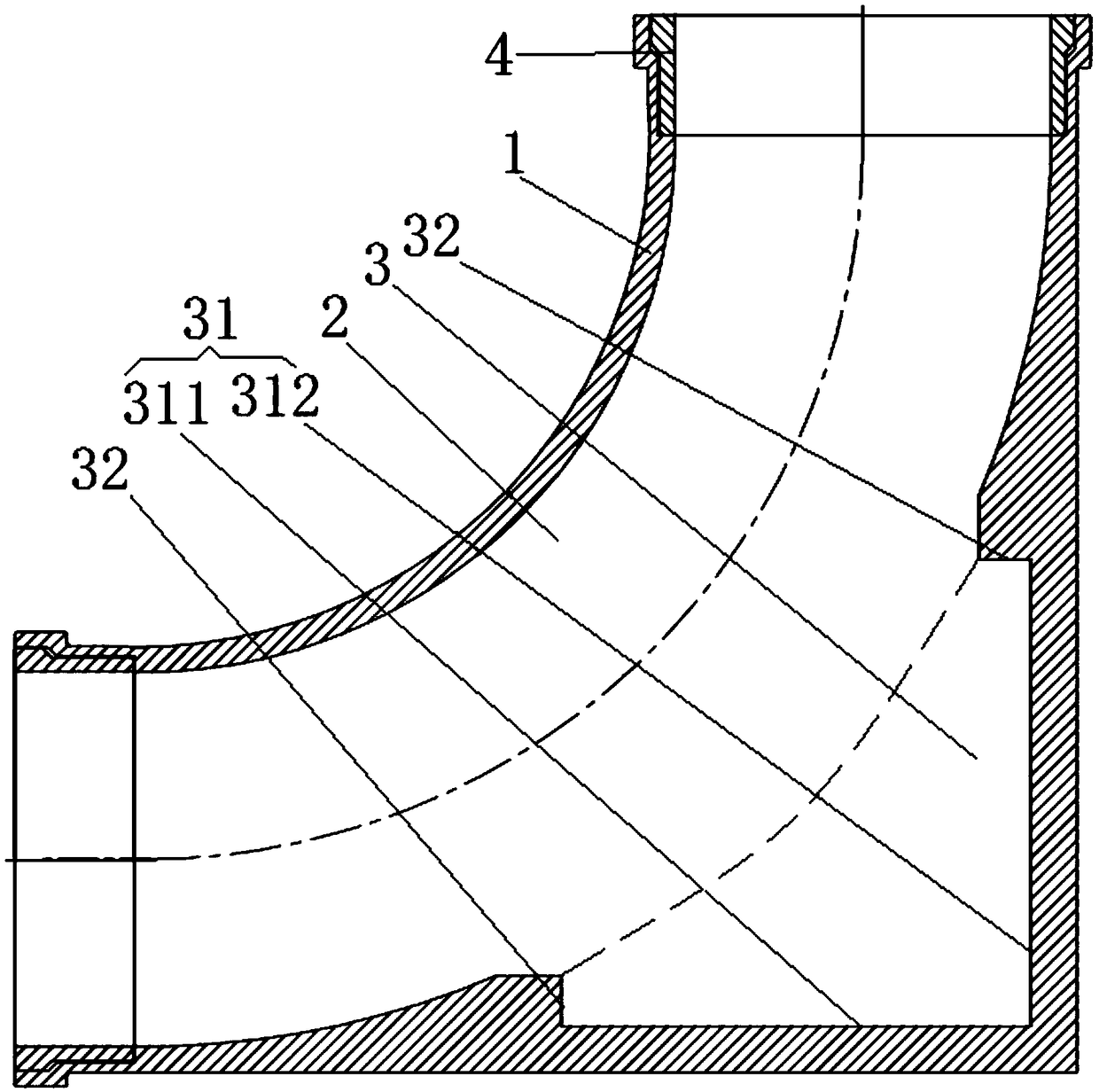

[0023] Such as figure 1 As shown, a self-filling elbow proposed by the embodiment of the present invention includes an elbow body 1, the elbow body 1 is in the shape of a shoe as a whole, and the elbow body 1 can use wear-resistant cast iron as the base body, and the elbow body 1 At least one section of the internally formed pipeline is an arc-shaped pipeline 2, and the elbow body 1 is provided with a groove 3 on the outer arc side of the section of the arc-shaped pipeline 2, which can be filled with and retain the material transported by the pipeline. Since the bent pipe body 1 of the embodiment of the present invention is provided with a groove 3 on the outer arc side of the arc-shaped pipe 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com