A kind of UV curing glass protection ink and preparation method thereof

A technology for protecting ink and glass, applied in ink, household appliances, applications, etc., can solve the problems of increasing labor and material costs, ink falling off into pieces, and consuming production time, achieving easy purchase, reducing rework rate, and improving production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

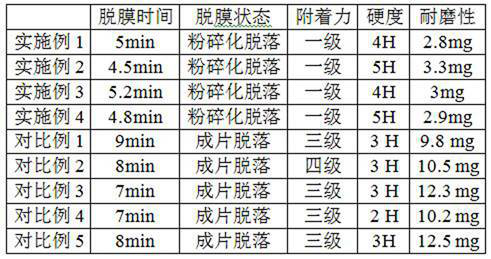

Examples

preparation example Construction

[0036] In a second aspect, the present invention also provides a method for preparing the above-mentioned UV curing glass protective ink, comprising the steps of:

[0037] Mix and disperse trifunctional polyurethane acrylic resin, monofunctional UV-curable monomer, aluminum oxide, photoinitiator and auxiliary agent to obtain a compound; couple the compound obtained above with bisamino silane After the agent is mixed, disperse evenly, and then grind.

[0038] The fineness of the protective ink obtained after grinding is preferably 5-10 μm, more preferably 6-7 μm.

Embodiment 1

[0041] A kind of UV curable glass protection ink, by weight, described protection ink is made up of the following components: 50 parts of trifunctional polyurethane acrylic resin, 12 parts of monofunctional UV curable monomer, 12 parts of aluminum sesquioxide , 10 parts of photoinitiator, 2.5 parts of bisamino silane coupling agent, 3 parts of auxiliary agent.

[0042] The monofunctional UV-curable monomer is selected from N,N-dimethylacrylamide; the photoinitiator includes photoinitiator 1173; the bisamino-type silane coupling agent is KH-602; the The auxiliary agent is a defoamer, a leveling agent, and a dispersant; the defoamer is BYK-051 defoamer; the leveling agent is selected from polyether-modified polydimethylsiloxane; the dispersion The agent is EFKA-4009 dispersant.

[0043] Its preparation method comprises the following steps:

[0044] Mixing and dispersing trifunctional polyurethane acrylic resin, monofunctional UV-curable monomer, aluminum oxide, photoinitiator ...

Embodiment 2

[0047] A kind of UV curable glass protection ink, by weight, described protection ink is made up of the following components: 40 parts of trifunctional polyurethane acrylic resin, 10 parts of monofunctional UV curable monomer, 10 parts of aluminum oxide , 8 parts of photoinitiator, 2 parts of bisamino silane coupling agent, 2 parts of auxiliary agent.

[0048] The monofunctional UV-curable monomer is selected from acryloylmorpholine; the photoinitiator is photoinitiator 184; the diamino-type silane coupling agent is KH-602; the auxiliary agent is defoaming agent, leveling agent, dispersant; the defoamer is BYK-052 defoamer; the leveling agent is selected from fluorocarbon modified polyacrylate solution; the dispersant is EFKA-4010 dispersant.

[0049] Its preparation method comprises the following steps:

[0050] Mixing and dispersing trifunctional polyurethane acrylic resin, monofunctional UV-curable monomer, aluminum oxide, photoinitiator and auxiliary agent to obtain a com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com