Novel cross shaft detection device

A detection device and cross-axis technology, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve the problems of low detection efficiency and inability to adapt to automated production, and achieve the effect of improving efficiency and positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

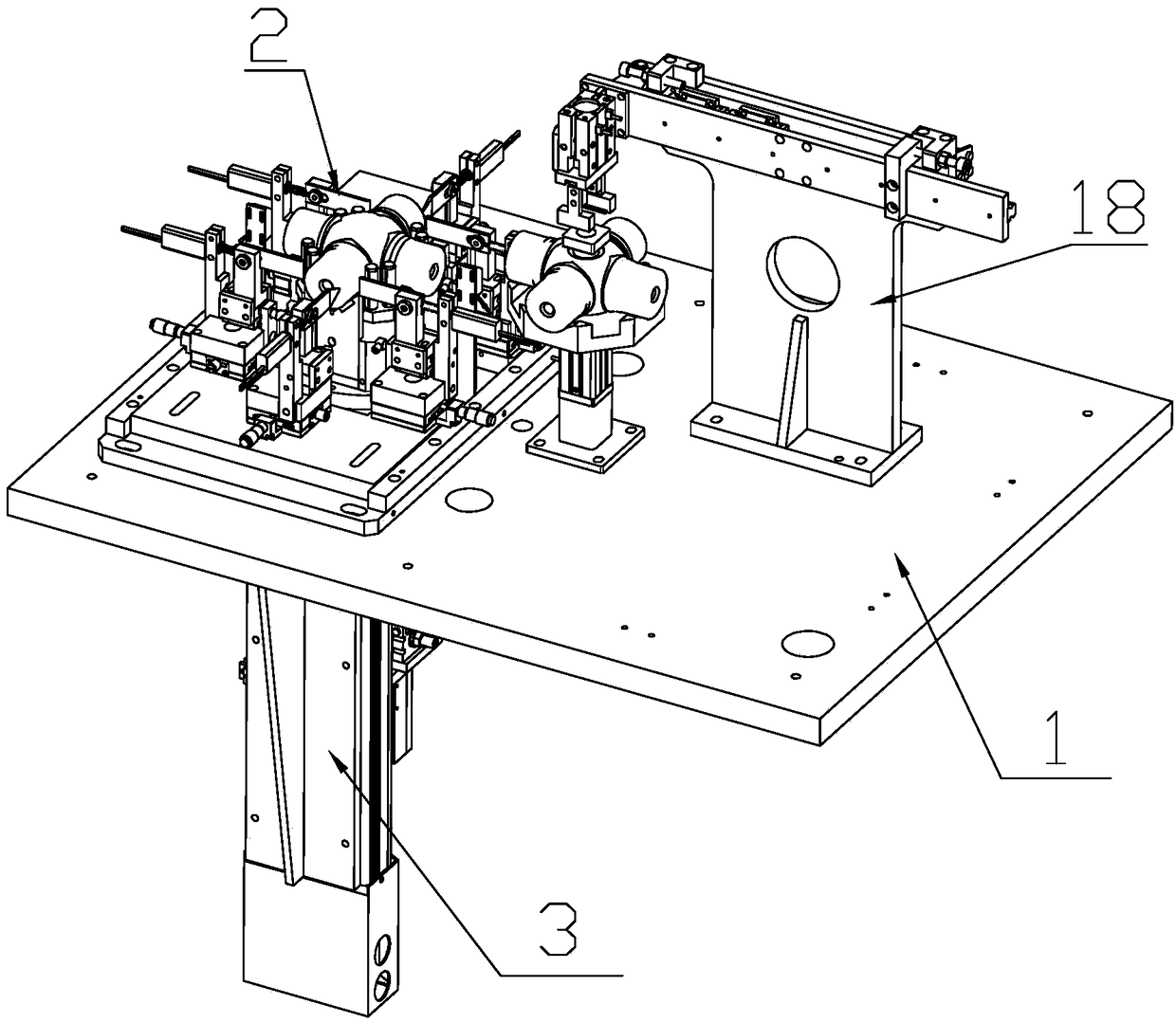

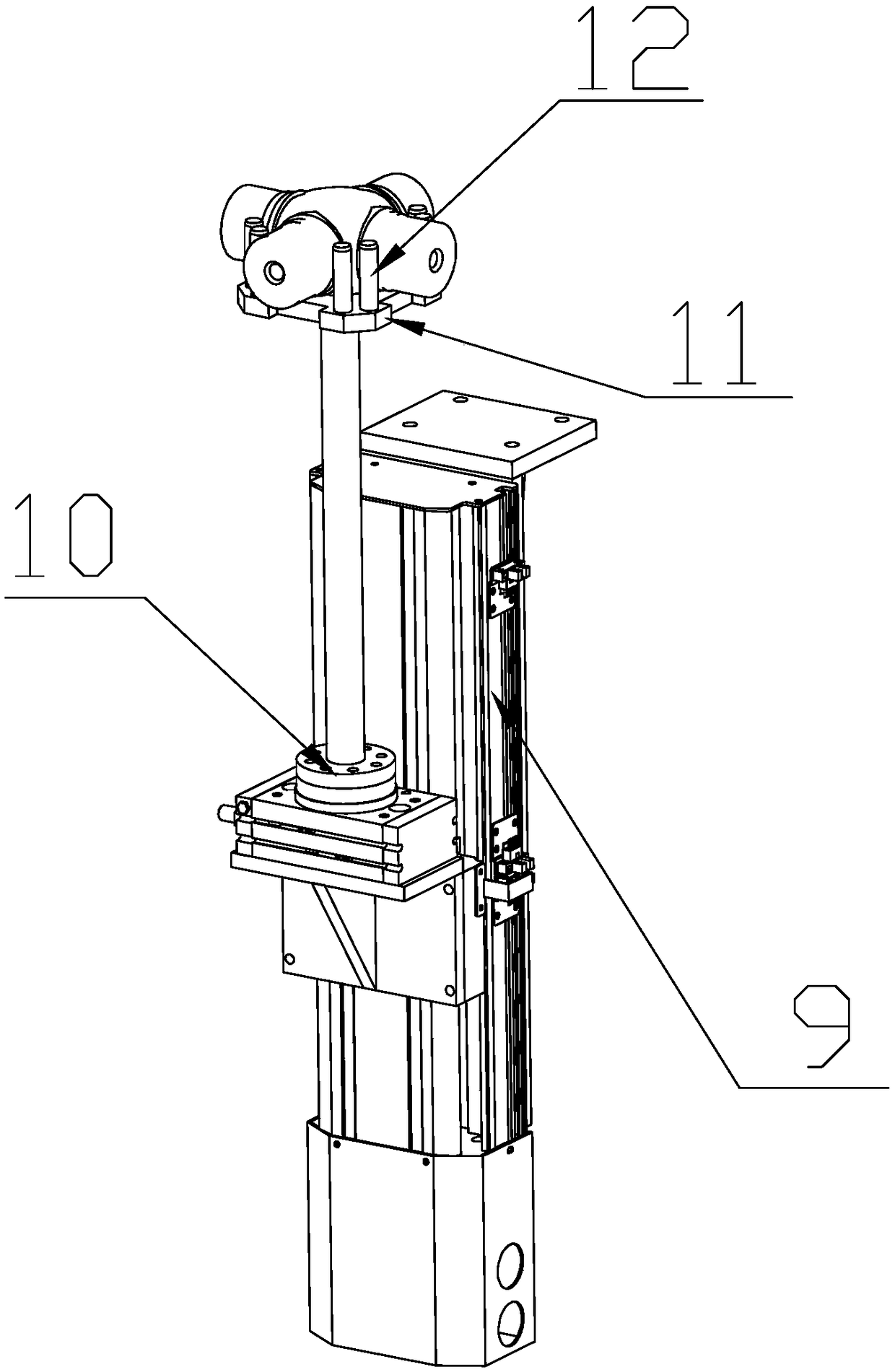

[0019] Such as Figure 1-Figure 4 The new cross axis detection device shown includes a workbench 1 , a detection component 2 arranged on the upper surface of the workbench 1 and a calibration component 3 arranged on the lower surface of the workbench 1 .

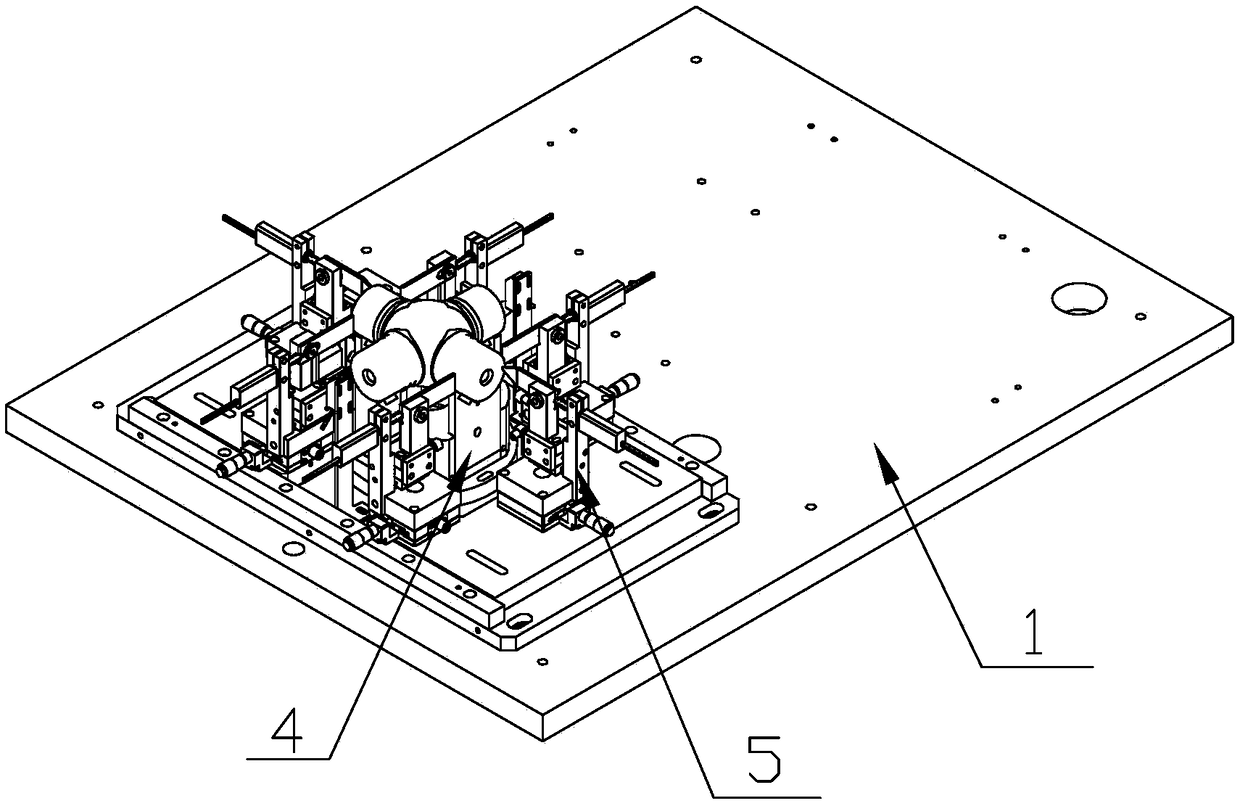

[0020] The detection part 2 described in this application includes a support 4 and a plurality of detection parts 5. The workbench 1 is a rectangular plate structure, the bottom of which is supported by a plurality of support columns (not shown in the figure). There is a square through hole (not shown in the figure) running through it on the table 1, and the support 4 includes four support plates (not shown in the figure) vertically arranged around the through hole and of equal height. ), the support plates are connected end to end to form a support frame with a rectangular cross section. The four support plates preferred in this application are of equal length, and the cross section of the support frame is square. There is...

Embodiment 2

[0026] This embodiment is a further improvement made on the basis of embodiment one, compared with embodiment one, as figure 1 and Figure 5 As shown, the present embodiment is also equipped with a clamping part 18 on the upper surface of the workbench 1. The clamping part 18 in this application is installed on the right side of the detection part 2. The clamping part 18 includes a support base plate 19, Sliding plate 20, clamping cylinder 21, finger cylinder 22, telescopic cylinder 23 and a workpiece storage table 25 for placing a standard cross shaft, the bottom of the support base plate 19 is detachably installed on the workbench 1 through a plurality of bolts, The clamping cylinder 21 is installed on the support base plate 19 and the piston rod of the clamping cylinder 21 is arranged horizontally. The piston rod of the clamping cylinder 21 can expand and contract towards the direction of the detection part 2. The slide plate 20 is slidably installed on the support base pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com