Method for analyzing meshing characteristic of gear pair

An analysis method and characteristic analysis technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of low efficiency in the analysis of gear pair meshing characteristics, and achieve the effect of high calculation accuracy and high calculation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

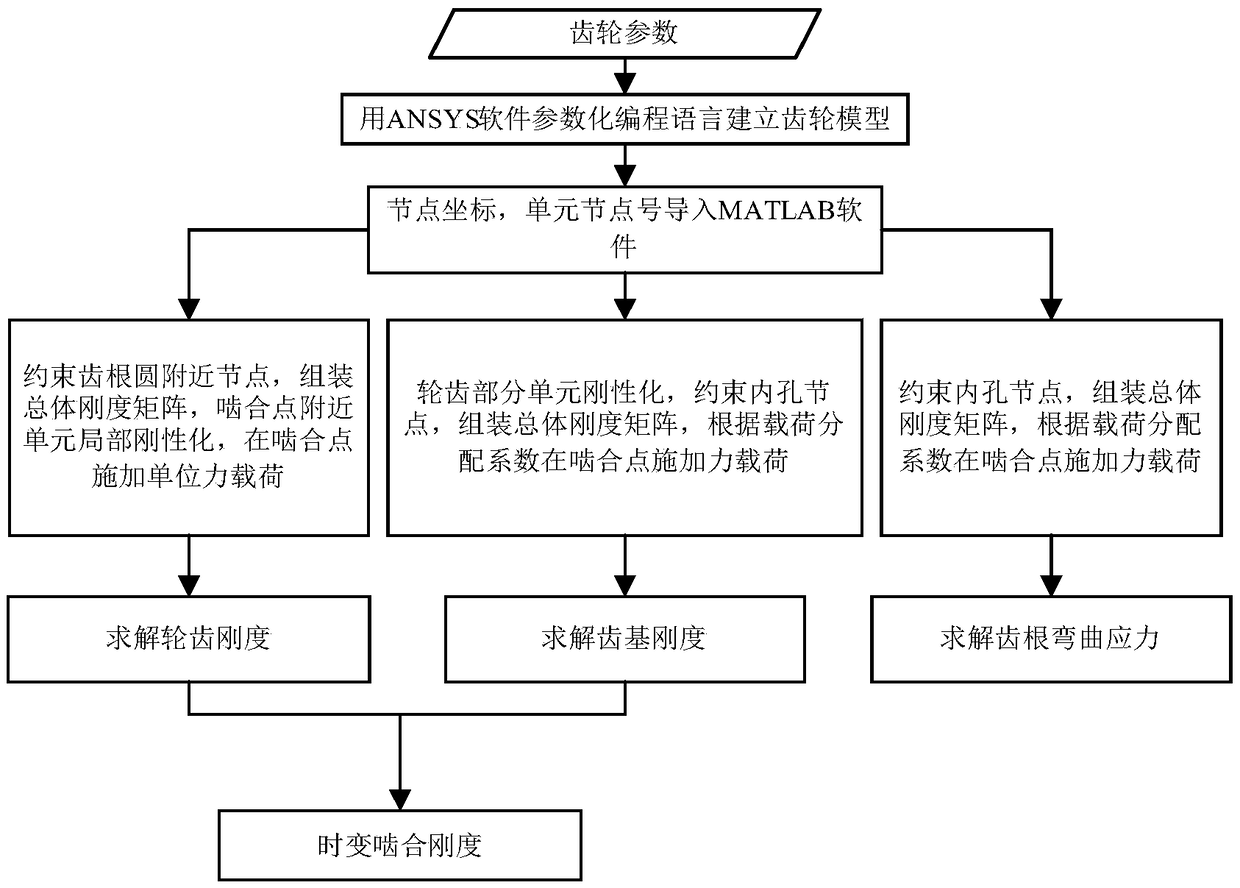

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

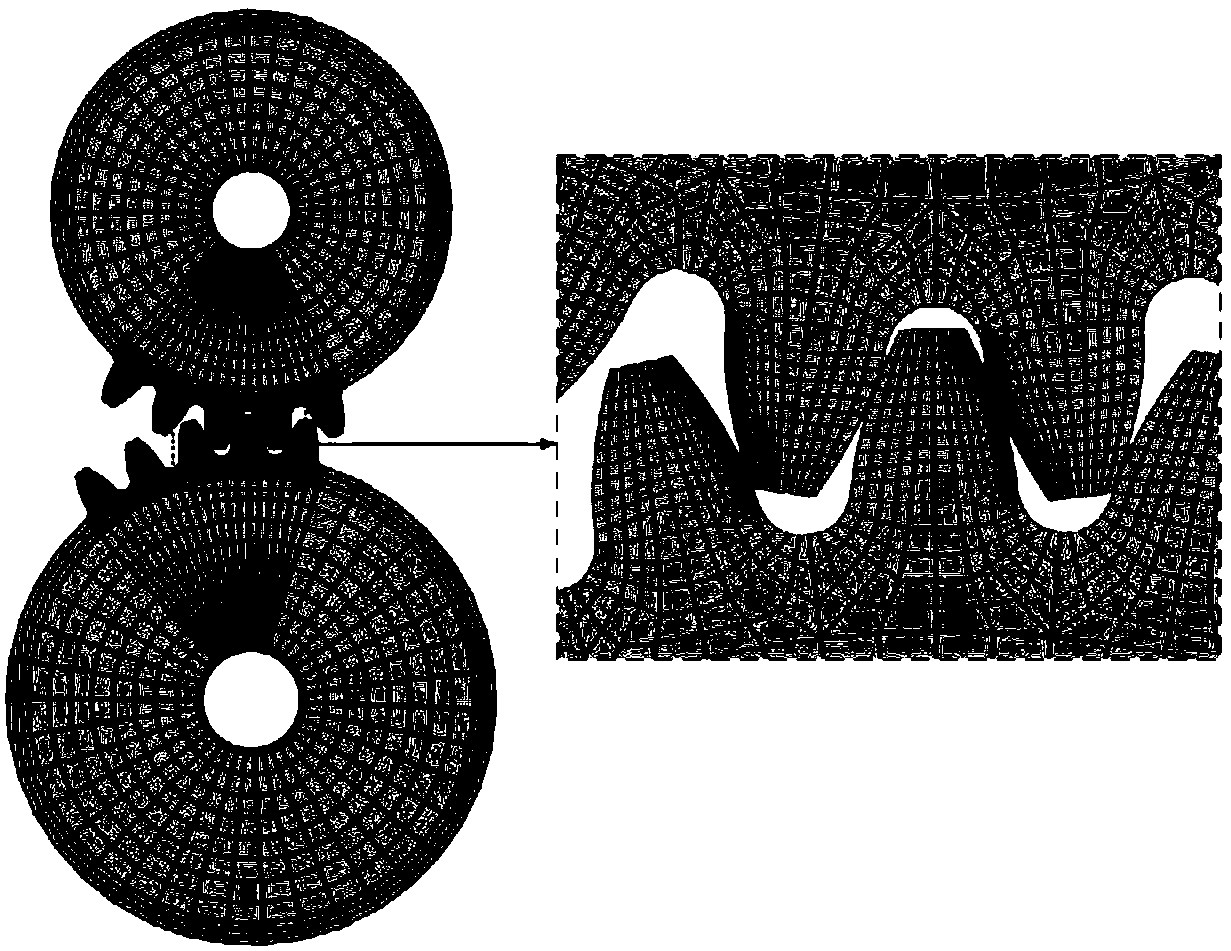

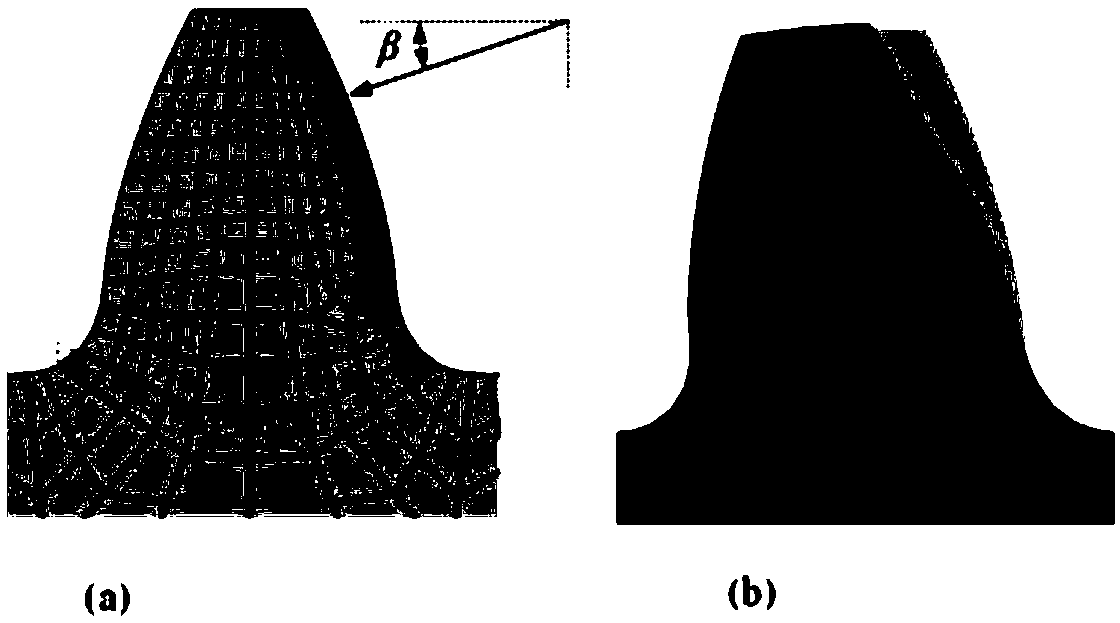

[0056] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below in conjunction with the accompanying drawings and through specific embodiments.

[0057] In order to facilitate the understanding of the present invention, the gear meshing theory is introduced as follows: According to the gear meshing theory, at any moment in a meshing cycle T of gear pair meshing, there are at most two pairs of gear teeth participating in meshing at the same time; In the meshing period T, the driving wheel or the driven wheel is in its meshing area, and at most 3 pairs of adjacent gears enter into the meshing area successively. That is, there are cases of early engagement and late engagement.

[0058] When calculating the time-varying mesh stiffness of a gear pair, it is necessary to calculate the tooth stiffness of the driving wheel and the driven wheel respectively. In the gear meshing theory, in the single tooth me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com