Rotary selective thinning-out cut type red date fruit collection device

A collection device and selective technology, applied in the direction of picking machines, agricultural machinery and implements, applications, etc., can solve the problems of high work intensity, troublesome collection, time-consuming and labor-intensive, etc., and achieve low labor costs, high work efficiency, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

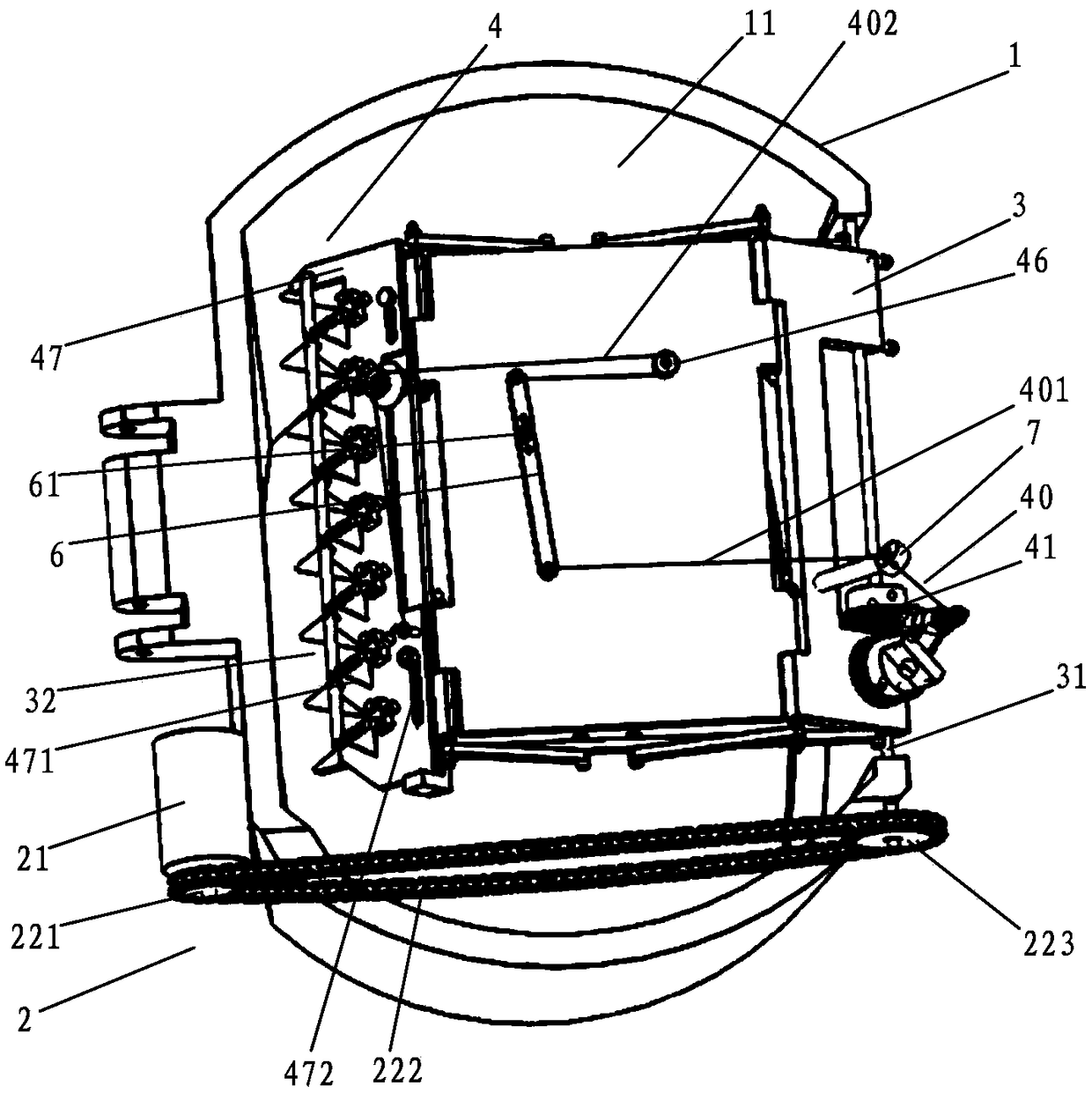

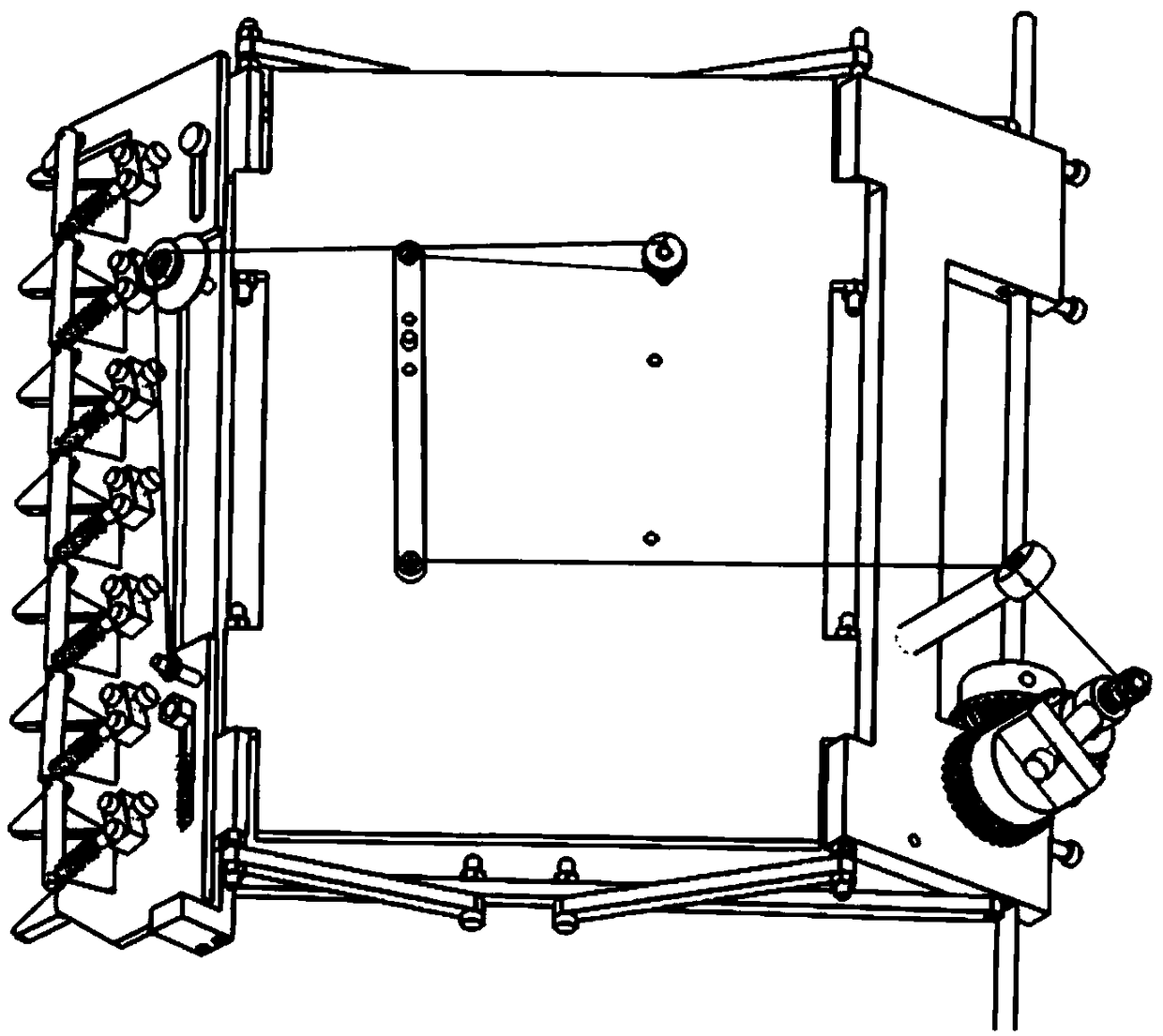

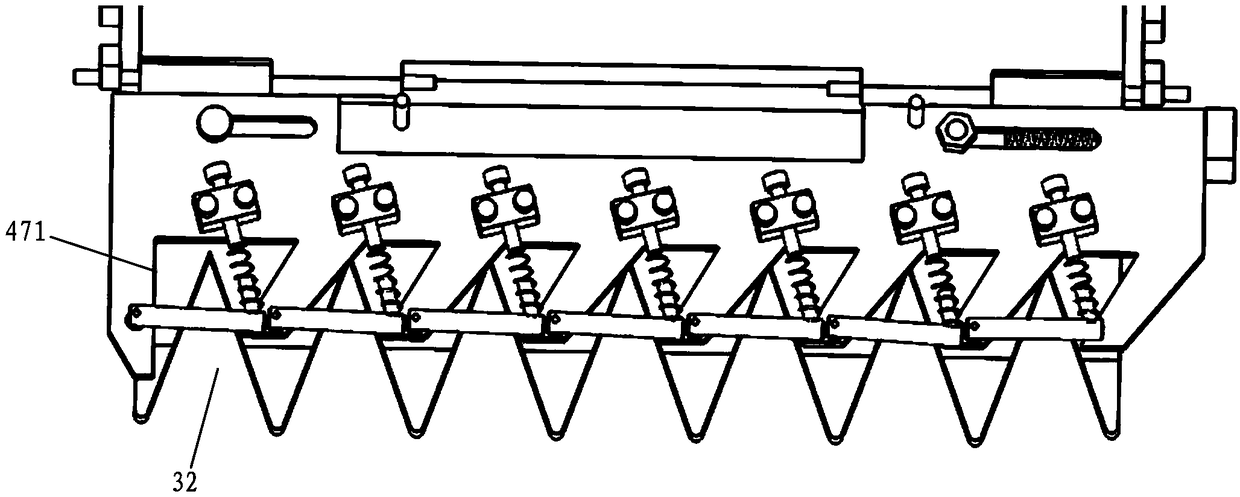

[0025] refer to Figure 1 to Figure 5 , this embodiment relates to a collection device, including a collection box 1 and a power device 2 installed on the collection box 1, a thinning shear plate 3 and a shearing device 4, and the thinning shear plate 3 is swingably installed on the collection box through a pin shaft 31 1, the thinning shearing plate 3 is located directly above the chamber 11 of the collection box 1; the power output end of the power device 2 is fixedly connected with the pin shaft 31, and the shearing device 4 includes a stay rope 40, a first cone Gear 41, the second bevel gear 42, driving gear 43, driven gear 44, winding wheel 45, guide wheel 46 and blade 47, described guide wheel 46 is rotatably installed on the thinning shearing plate 3, and described first cone The gear 41 is fixedly installed on the collection box 1, the second bevel gear 42 and the driving gear 43 are coaxially fixedly installed together by the first rotating shaft 48, and the first rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com