a brick mold

A technology of molds and mold bases, applied in the direction of molds, etc., can solve the problems of unchanged wiring and heavy quality, and achieve the effect of saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementations.

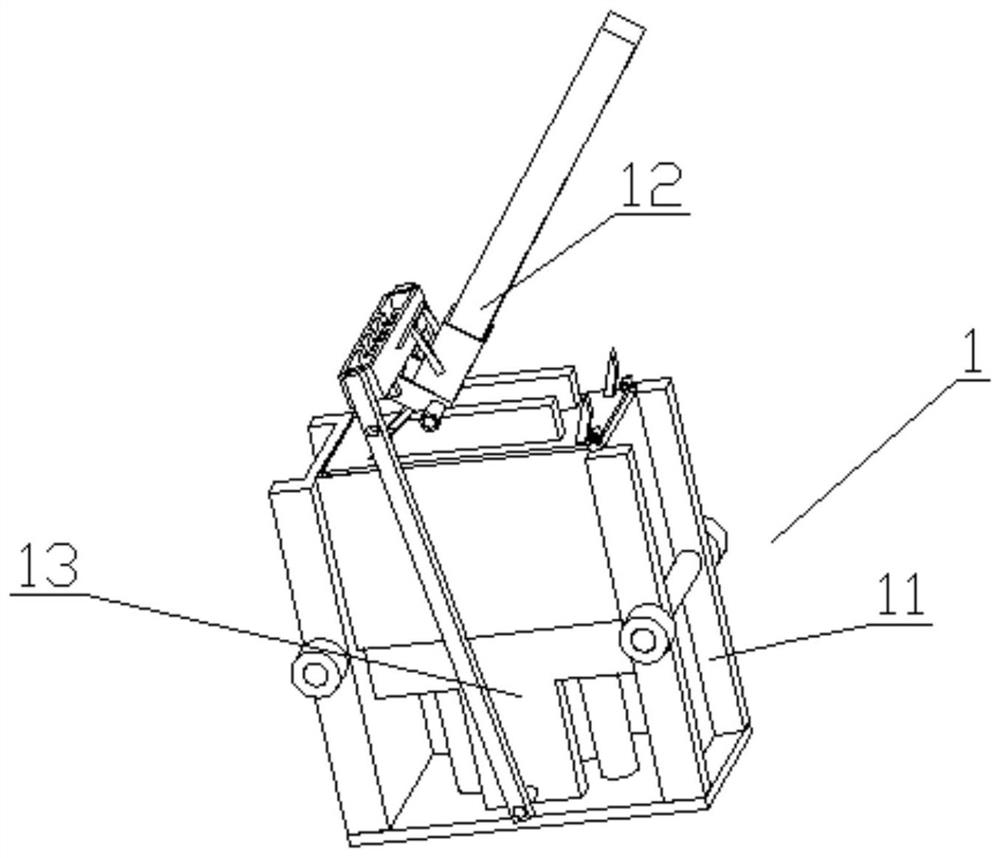

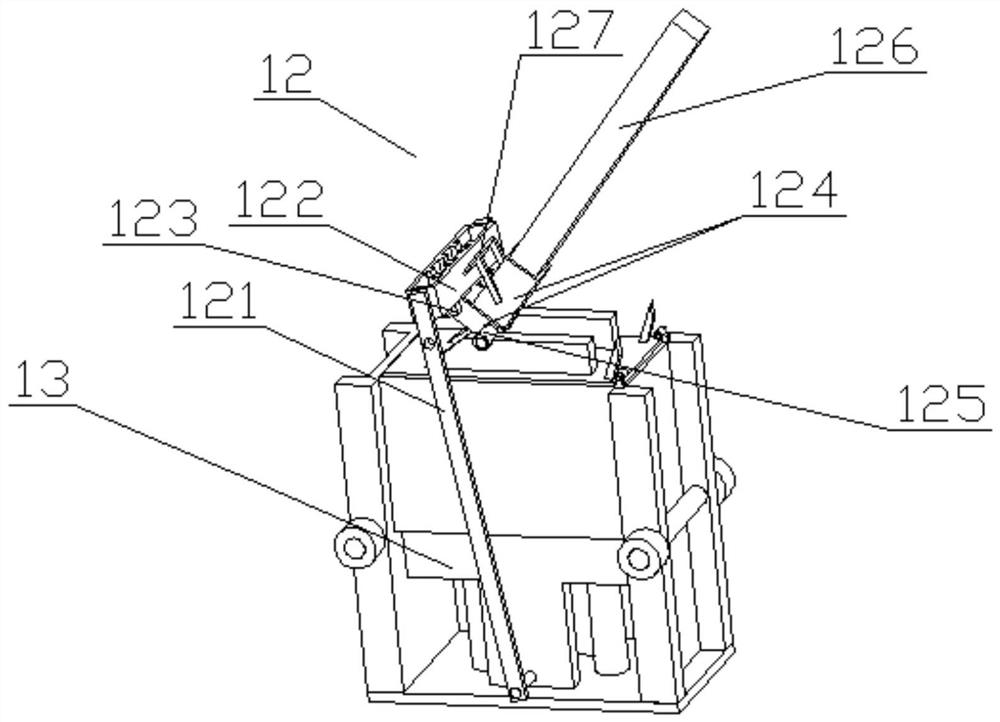

[0020] see Figure 1 to Figure 6 The present invention is: a brick-making mold, comprising a brick-making mold 11, an opening and closing mechanism 12 and an ejection mechanism 13, one end of the opening and closing mechanism 12 is connected with the brick-making mold 11, and drives the brick-making mold 11 to do opening and closing movement, and the other One end is connected with the ejector mechanism 13, and drives the ejector mechanism 13 to move up and down.

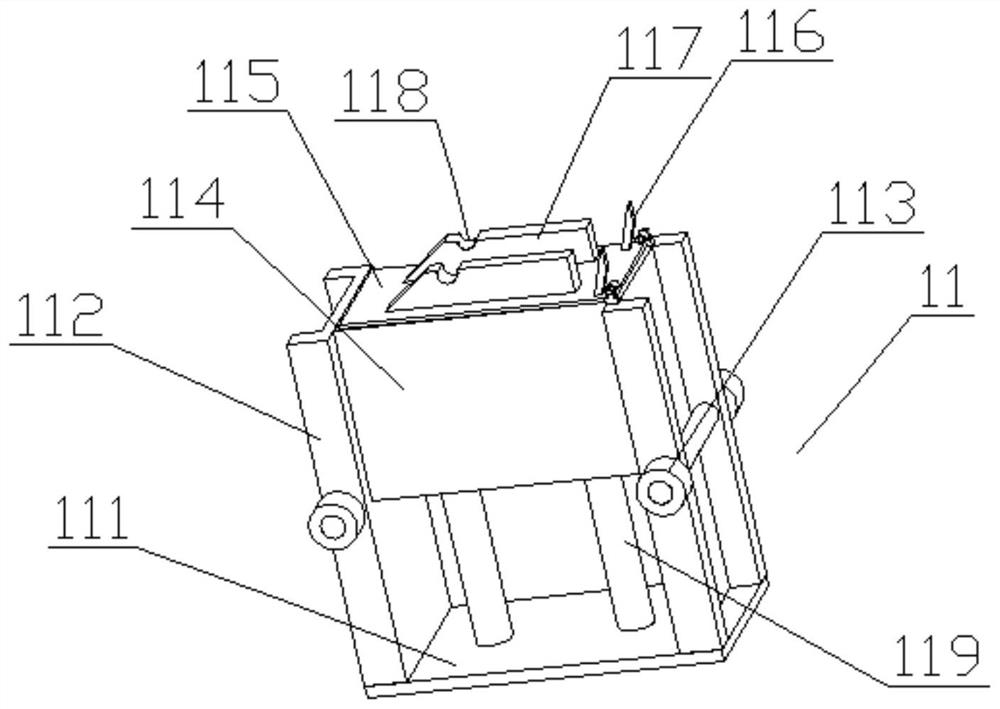

[0021] The brick-making mold 11 includes a mold base 111 , a support plate 112 is provided on both sides of the mold base 111 , a support roller 113 is provided on the support plate 112 , a mold 114 is fixedly connected to the upper end of the support plate 112 , a cover plate 115 is provided on the mold 114 , and the cover The plate 115 is hinged with the mold 114, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com