Wind power generation equipment with automatic opening and closing type fan blades

A kind of wind power generation equipment, open and close technology, applied in the direction of wind power generation, wind power engine, wind power engine at right angles to the wind direction, etc., can solve the problems such as the reduction of wind energy utilization rate, and achieve simple structure, high stability, and high execution efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

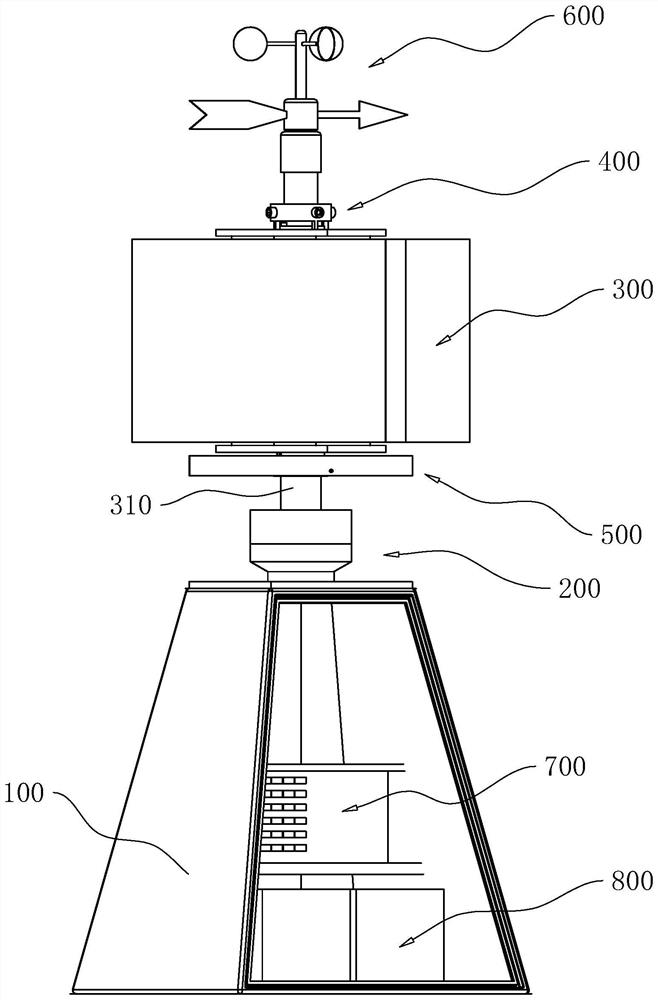

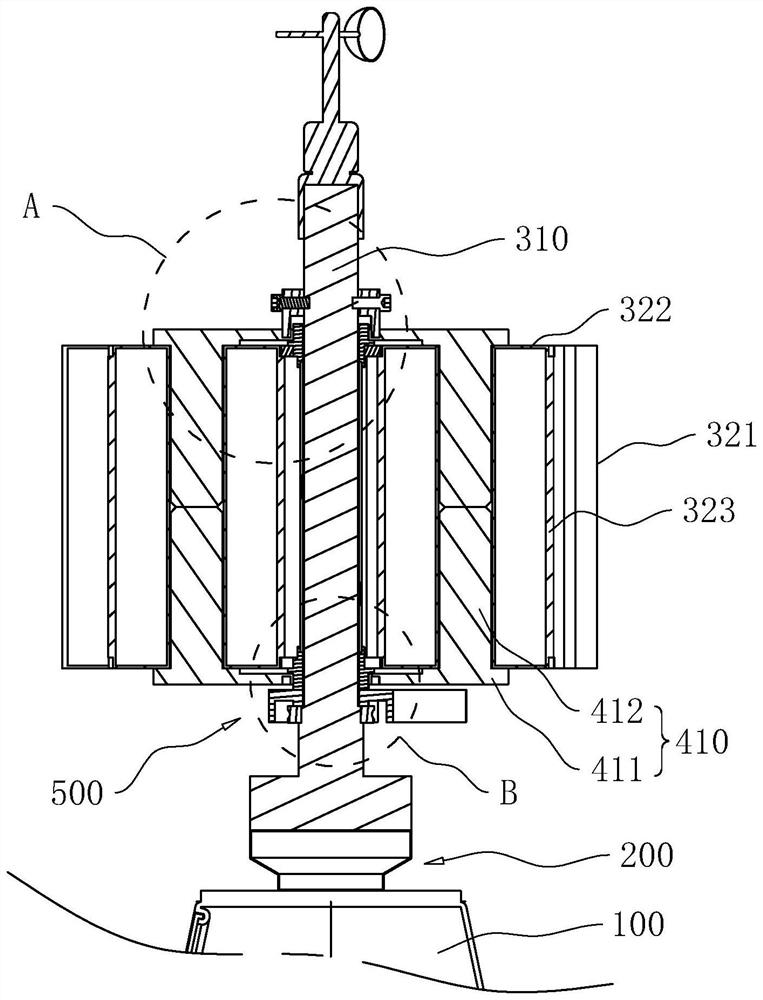

[0042] refer to figure 1 , The automatic opening and closing blade wind power generation equipment includes a fixed base 100, a power generation device 200, a blade module 300, a locking device 400, an opening and closing device 500, a wind speed sensing device 600, a control device 700 and an energy storage device 800. The wind speed sensing device 600 monitors the wind speed of the environment, the control device 700 controls the operation of the opening and closing device 500 according to different wind speeds, and changes the degree of opening and closing of the fan blade module 300, and the fan blade module 300 rotates under the action of the wind to make the power generation device 200 To generate electricity, the energy storage device 800 can store electric energy.

[0043] refer to figure 1 , the fixed base 100 is fixedly placed on the ground. In this embodiment, the fixed base 100 is in the shape of a hollow prism, and the control device 700 and the energy storage de...

Embodiment 2

[0051] refer to Figure 7 The difference between this embodiment and Embodiment 1 is that: there are multiple groups of fan blade modules 300, and the fan rods 310 in the plurality of groups of fan blade modules 300 are fixedly connected coaxially. By arranging multiple sets of fan blade modules 300, the utilization rate of wind energy is further improved.

Embodiment 3

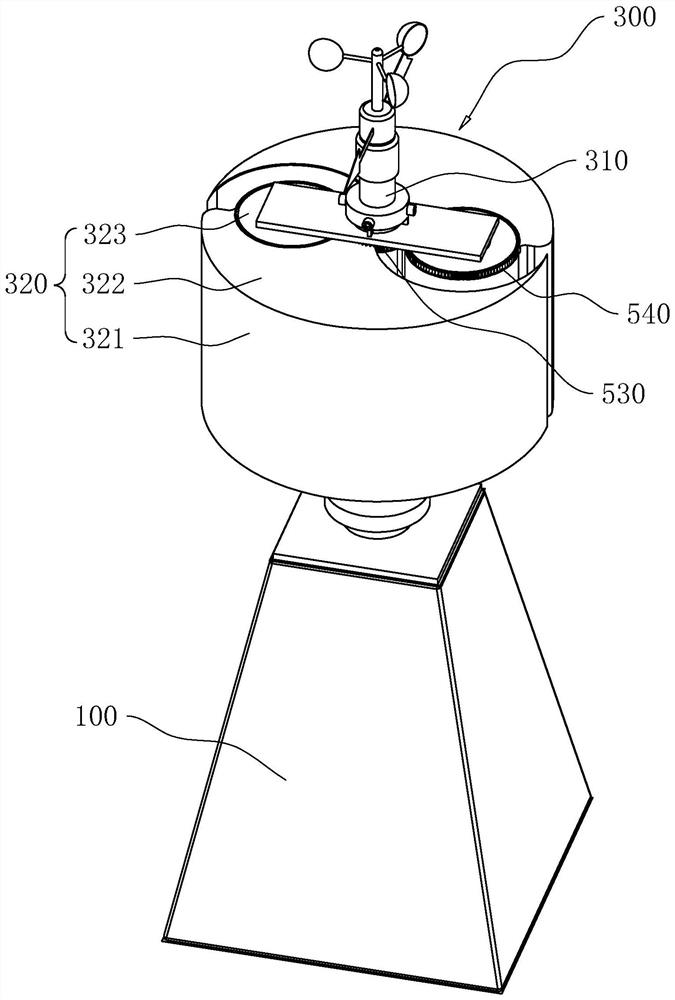

[0053] The difference between the present embodiment and the first embodiment is that the fan blade 320 includes an integrally formed enclosing portion 321 and two enclosing portions 322 , and the enclosing portion 321 is located between the two enclosing portions 322 . The enclosing part 322 is a flat plate structure arranged horizontally, and the closing part 321 is a plate-shaped structure arranged vertically. The closed parts 321 of the two fan blades 320 can be rotated to form closed patterns such as ellipse, rectangle and polygon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com