EPE sheet cutting machine with mincing mechanism

A board cutting machine, pearl cotton board technology, applied in the direction of stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of inconvenient production process, high cost, low efficiency, etc., and achieve the effect of easy reshaping and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following figures further illustrate the present invention in conjunction with the accompanying drawings and specific embodiments.

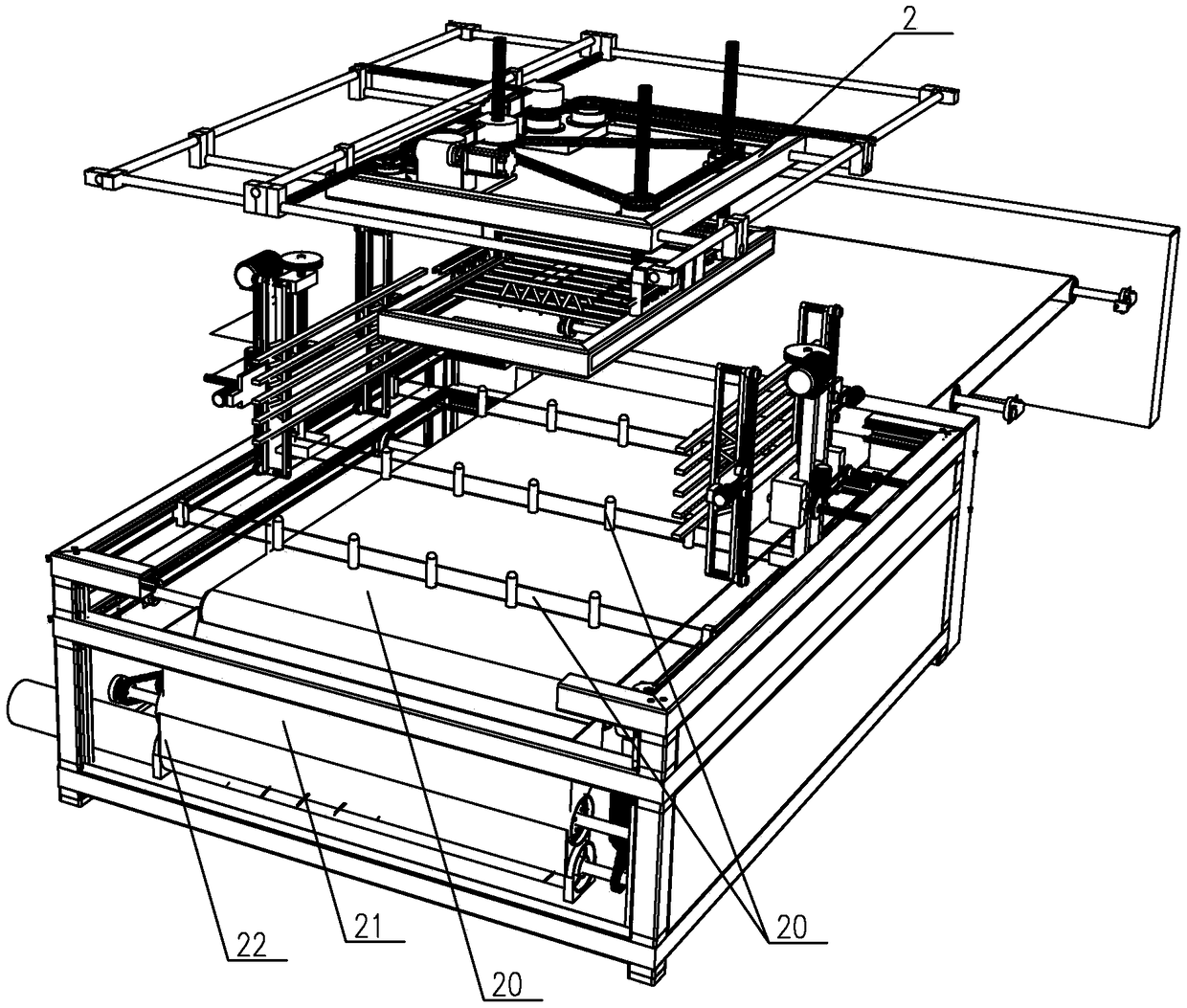

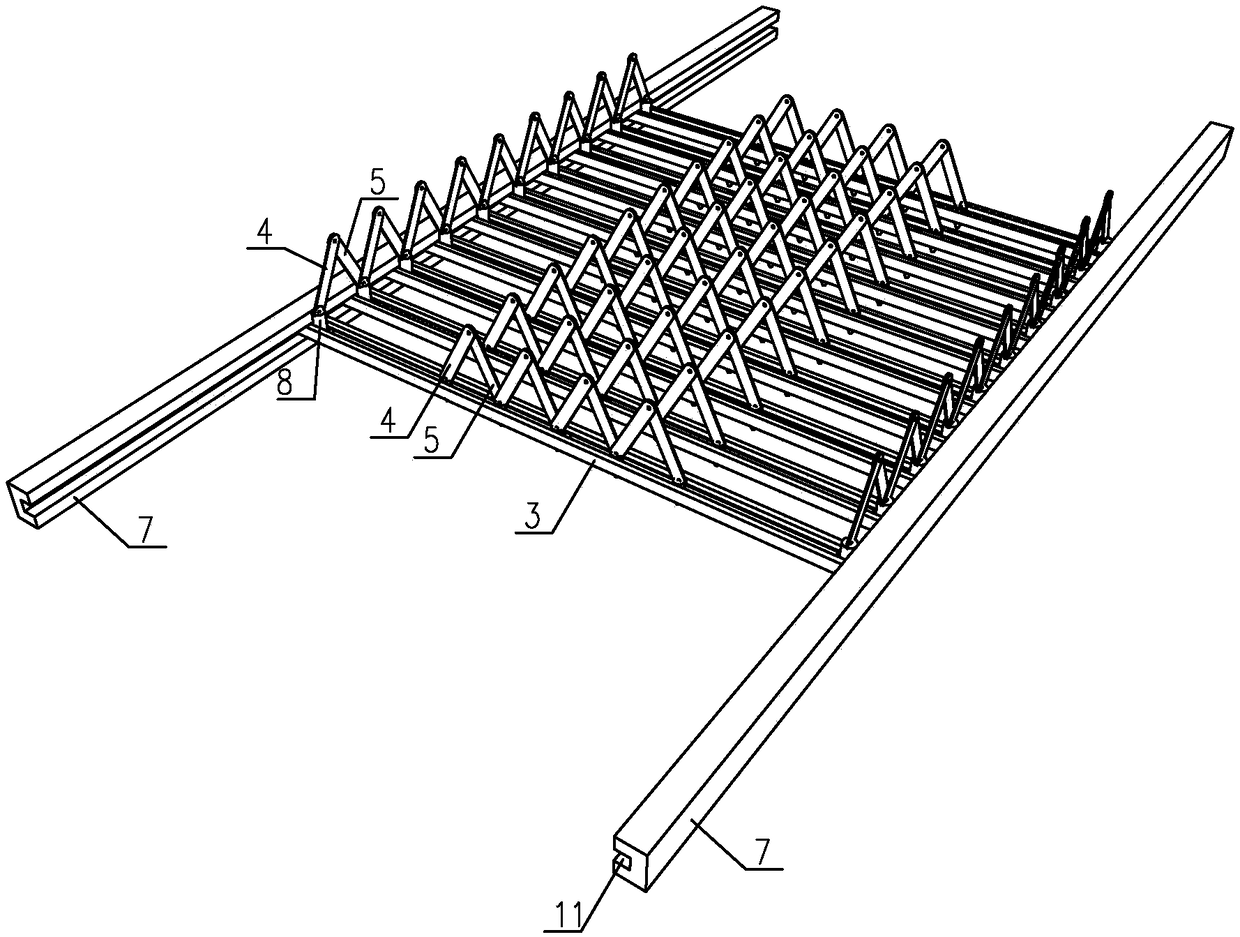

[0036] Such as figure 1 A kind of pearl cotton board cutting machine with shredding mechanism shown, comprises the fixed frame 1 of product to be cut, is provided with cutting device 2 above described fixed frame 1 of product to be cut, and described cutting device 2 comprises and distributes a plurality of The cutting nozzle matrix of the cutting nozzle 6 also includes a pitch adjustment mechanism for adjusting the spacing of the cutting nozzles 6, an up and down adjustment mechanism for adjusting the overall movement of the cutting nozzle lattice, and a path adjustment mechanism for adjusting the cutting path of the cutting nozzle lattice.

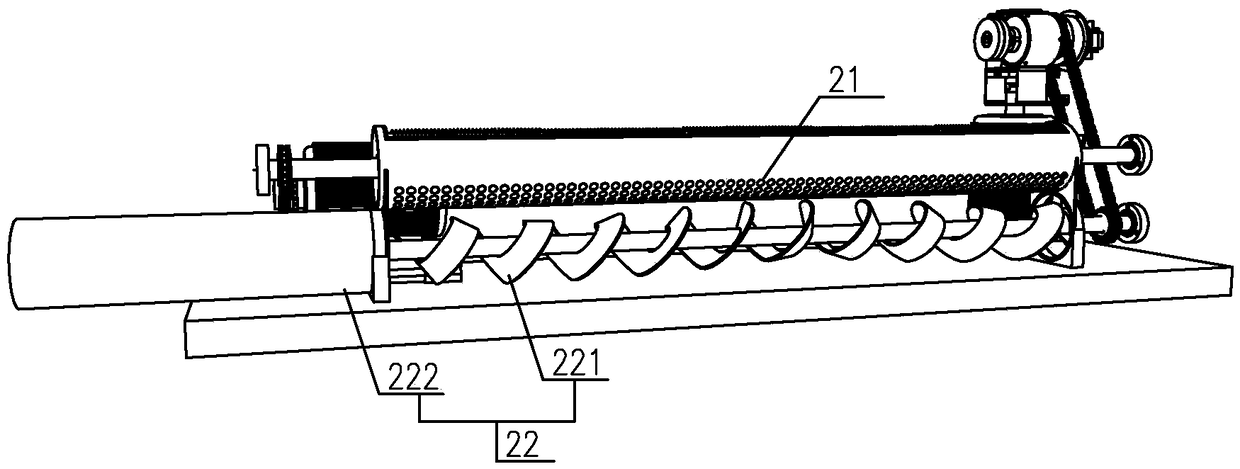

[0037] A conveyor belt 20 is provided below the fixed frame of the product to be cut, and the end of the conveyor belt 20 is provided with a pearl cotton board crushing mechanism 21, the upper pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com