Automobile direction sensor

A direction sensor and sensor technology, applied in vehicle parts, steering mechanism, transportation and packaging, etc., can solve the problems of affecting the sensor's sensing accuracy and difficult to control the level, so as to improve convenience, avoid automatic reset, and improve sensing accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

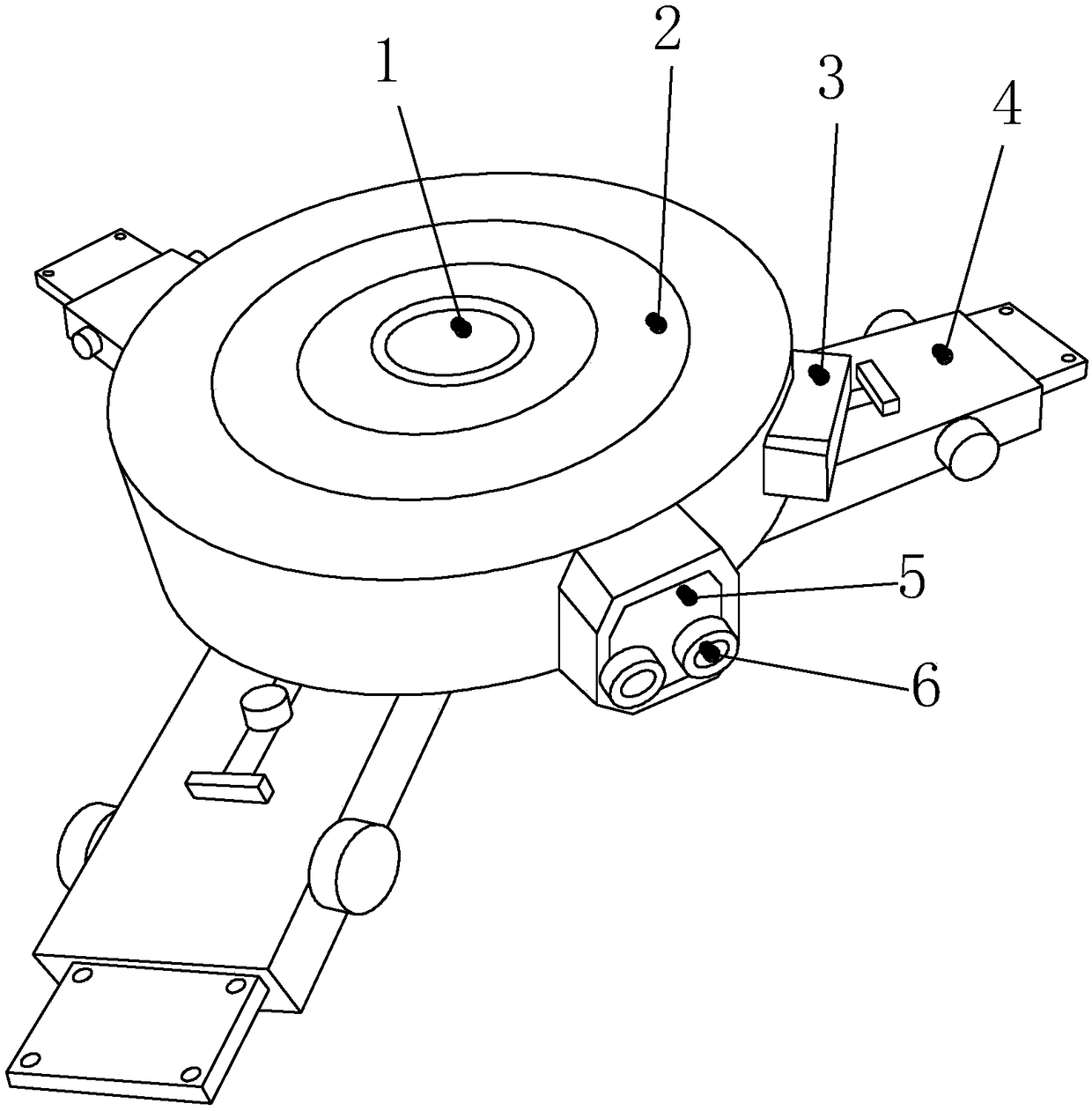

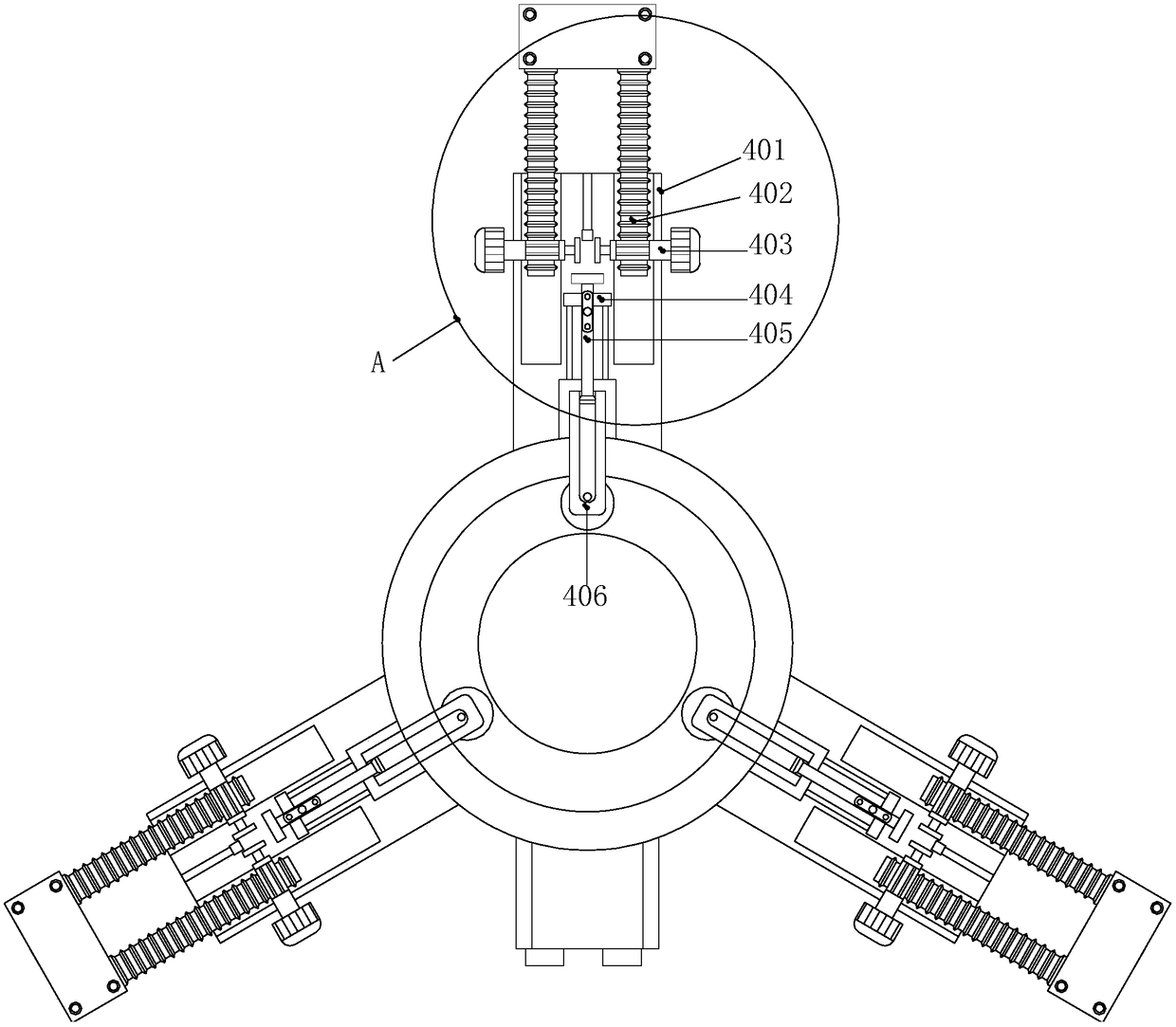

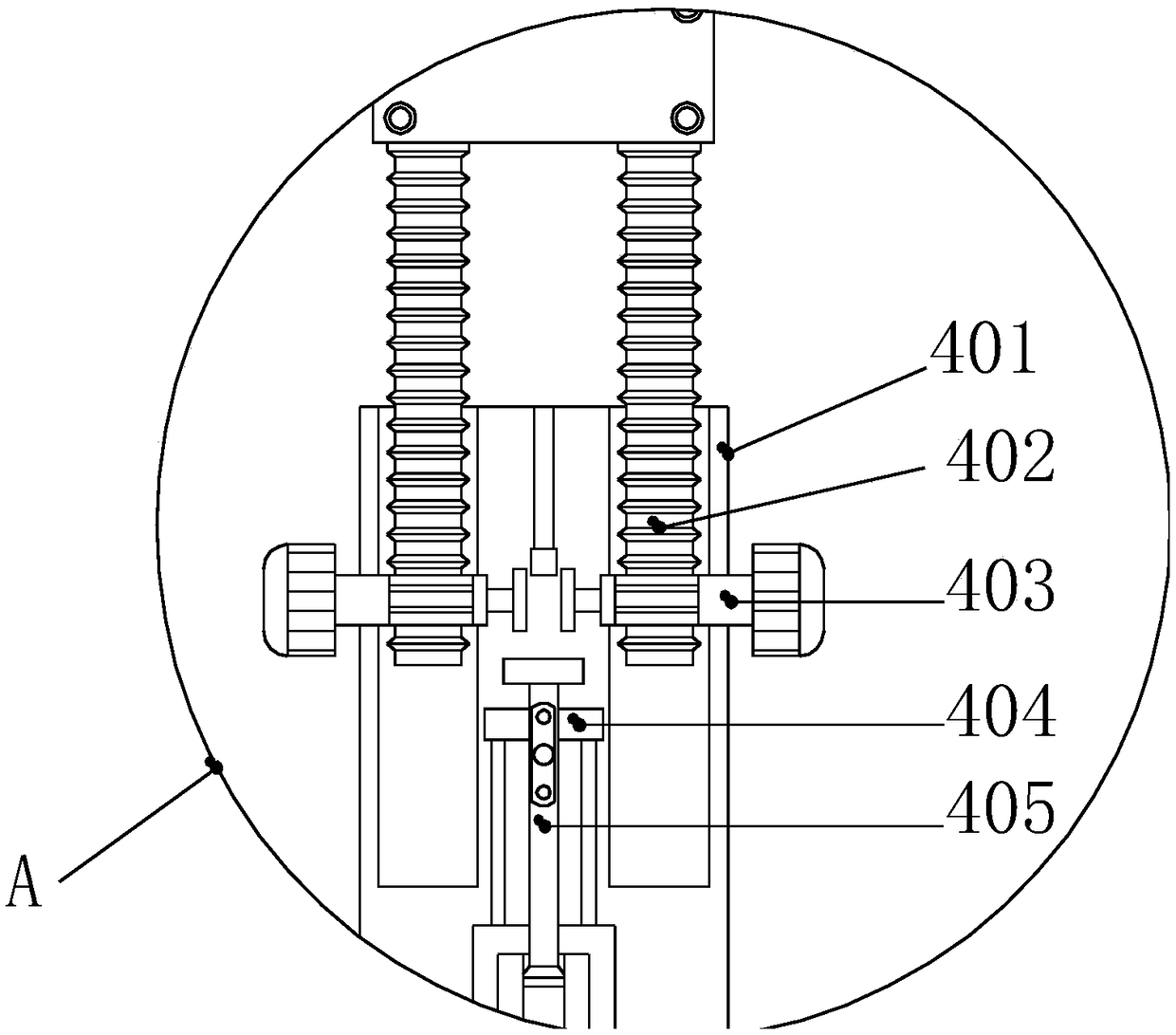

[0022] see Figure 1-Figure 5, the present invention provides an automobile direction sensor, the structure of which includes a steering column bushing 1, a sensing wheel 2, a position sensor 3, a mounting seat 4, a data sensor 5, and a joint 6, and the steering column bushing 1 is arranged on the sensing wheel 2 The middle part is an integrated structure, the right end of the sensing wheel 2 is provided with a position sensor 3, the position sensor 3 and the data sensor 5 are both rectangular structures, and the data sensor 5 is arranged at the right front end of the sensing wheel 2 by embedding , there are two joints 6, and they are installed on the surface of the data sensor 5 by snap-fitting. The seat 4 includes a shell assembly 401, a positioning mechanism 402, a telescopic control mechanism 403, a limit mechanism 404, a transmission device 405, and a negative pressure device 406. There are two telescopic control mechanisms 403 in total, and they are arranged at both end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com