Roller suitable for soft bag settling machine

A technology of rollers and soft bags, applied in the direction of rollers, rollers, conveyor objects, etc., can solve the problems of small gap, angle deviation, stacking and overlapping of soft bags, etc., achieve direct and stable speed transmission, and avoid slipping and throwing. The effect of fast output and rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

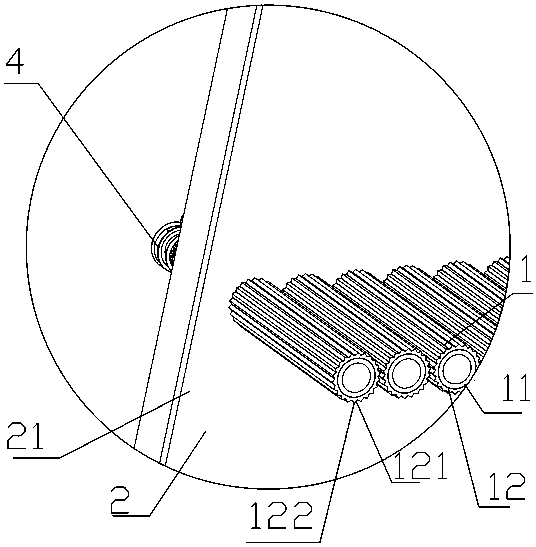

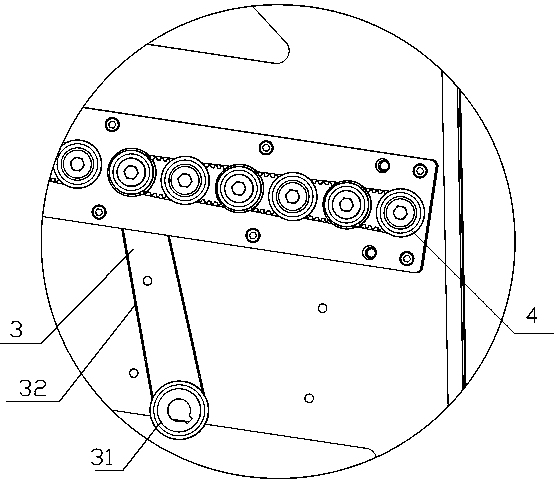

[0030] Example 1, such as figure 1 As shown, the main support 2 is included, and the main support 2 includes a blocking wall 21 extending vertically, and the blocking wall 21 can stand on the ground.

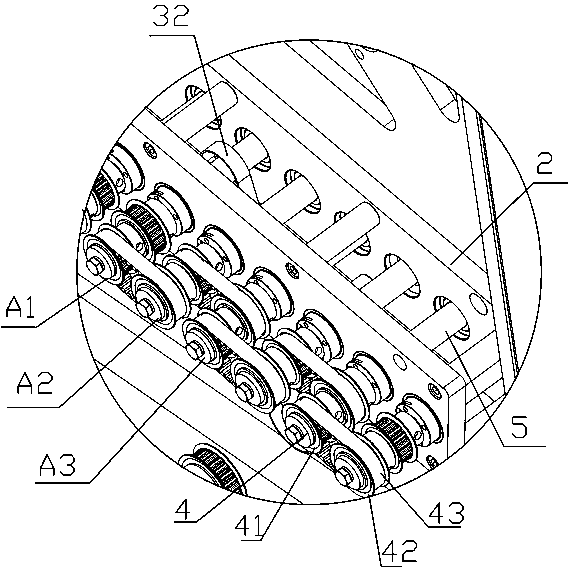

[0031] The barrier wall 21 is provided with a roller body 1, and there may be multiple roller bodies 1 arranged obliquely. Specifically, the height of the roller body 1 from the ground gradually increases according to the conveying direction of the soft bag. The roller body 1 can rotate by itself under the action of the driving structure. The driving structure can be a structure such as a motor, a belt, and a gear transmission device in the prior art, and will not be described in detail here.

[0032] The height of the plurality of roller bodies 1 from the ground is gradually increased to facilitate the distance between the plurality of soft bags during the transmission process. Specifically, because the surface of the soft bag is relatively smooth, when there is a height diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com