Flexible tobacco conveying system of AGV (Automatic Guided Vehicle)

A conveying system and trolley technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of affecting tobacco packaging, high maintenance costs, and high maintenance frequency, so as to ensure the quality of tobacco, reduce maintenance costs, and maintain long-term effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

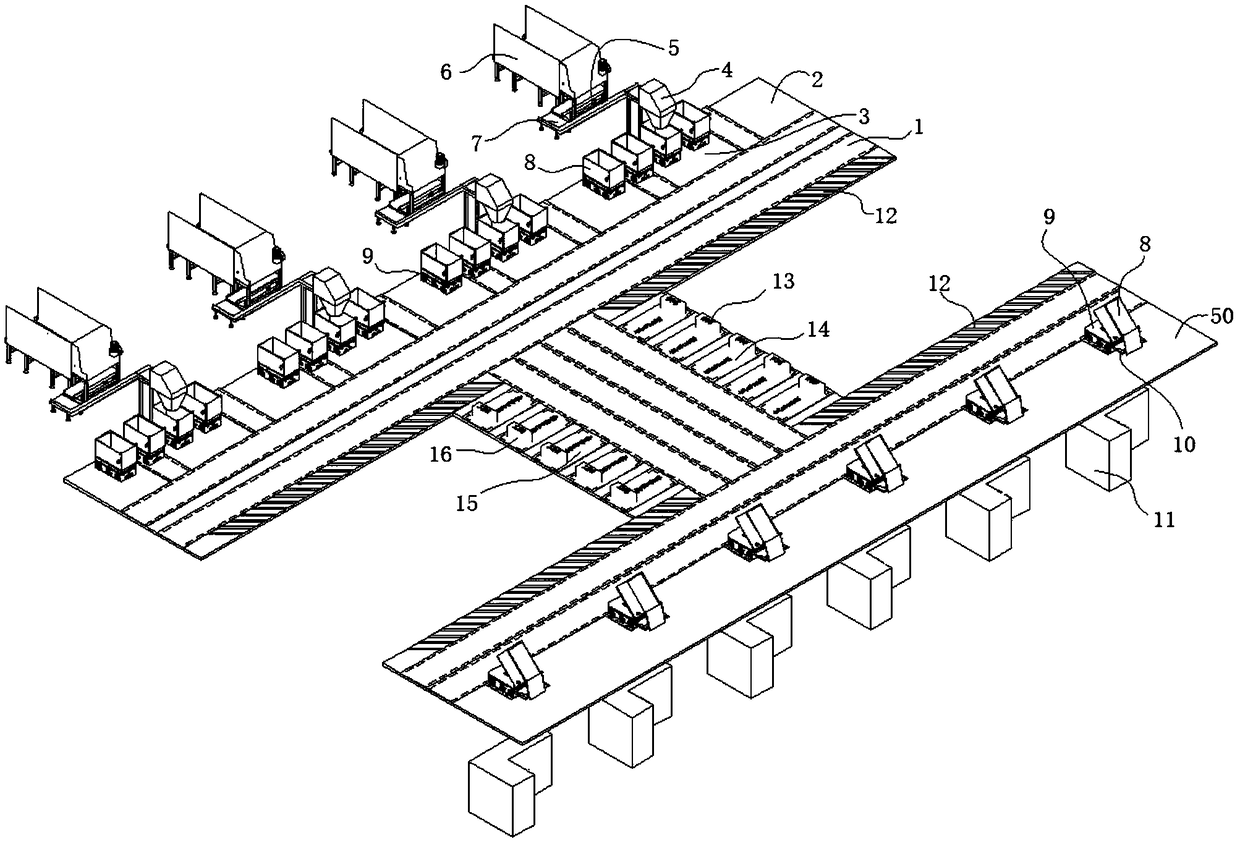

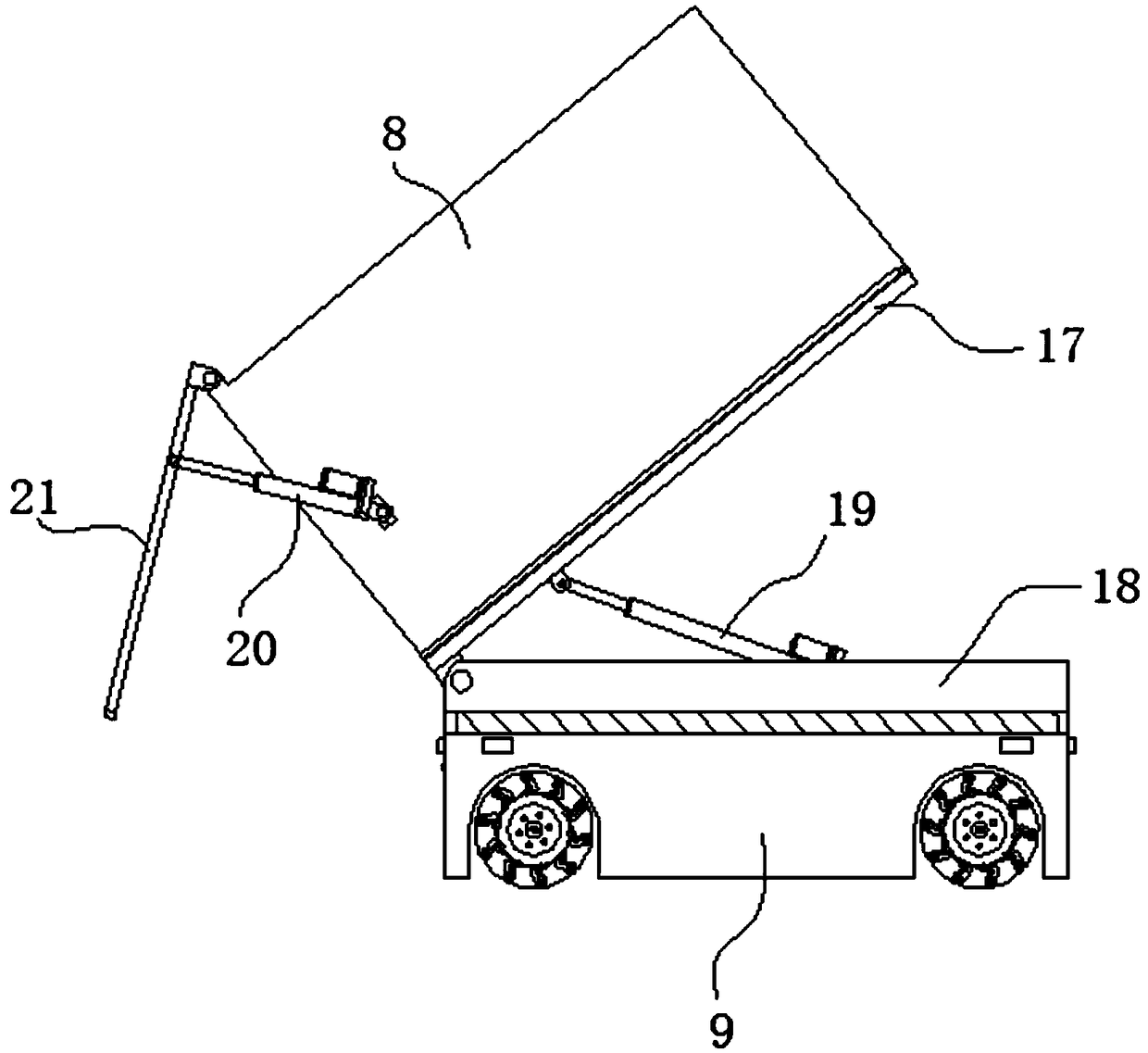

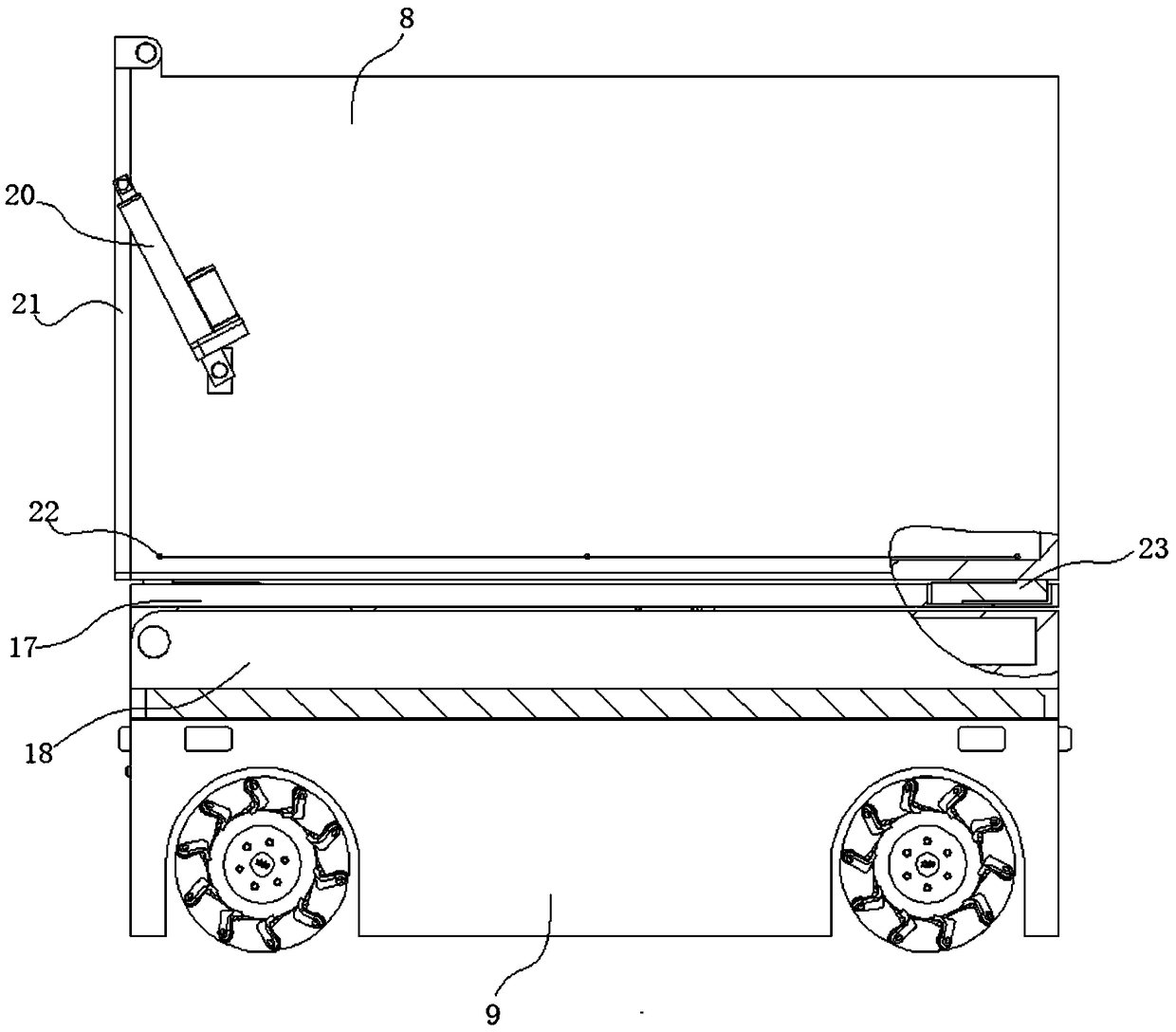

[0042] Such as figure 1 and figure 2As shown, an AGV trolley flexible shredded tobacco conveying system includes a controller, multiple silk storage cabinets 6, multiple cigarette making machines 11, several AGV trolleys 9 for loading transfer boxes 8 and AGVs for AGV trolley 9 driving trolley runway 1; each silk storage cabinet 6 is provided with at least one silk outlet, each silk outlet is provided with a wire outlet conveyor 5, and the output end of the wire outlet conveyor 5 is provided with a lifting conveyor 7, and the lifting conveyor The output end of 7 is equipped with a loading hopper 4; the two ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com