Hot-melt observation device and cable hdpe waterproof cover including it

An observation device and hot-melt technology, which is applied in the field of stay cables, can solve the problems of difficult observation of the protruding length of the moving pin and difficult judgment of the hot-melt effect, and achieve the effect of observing whether the hot-melt is good or not

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

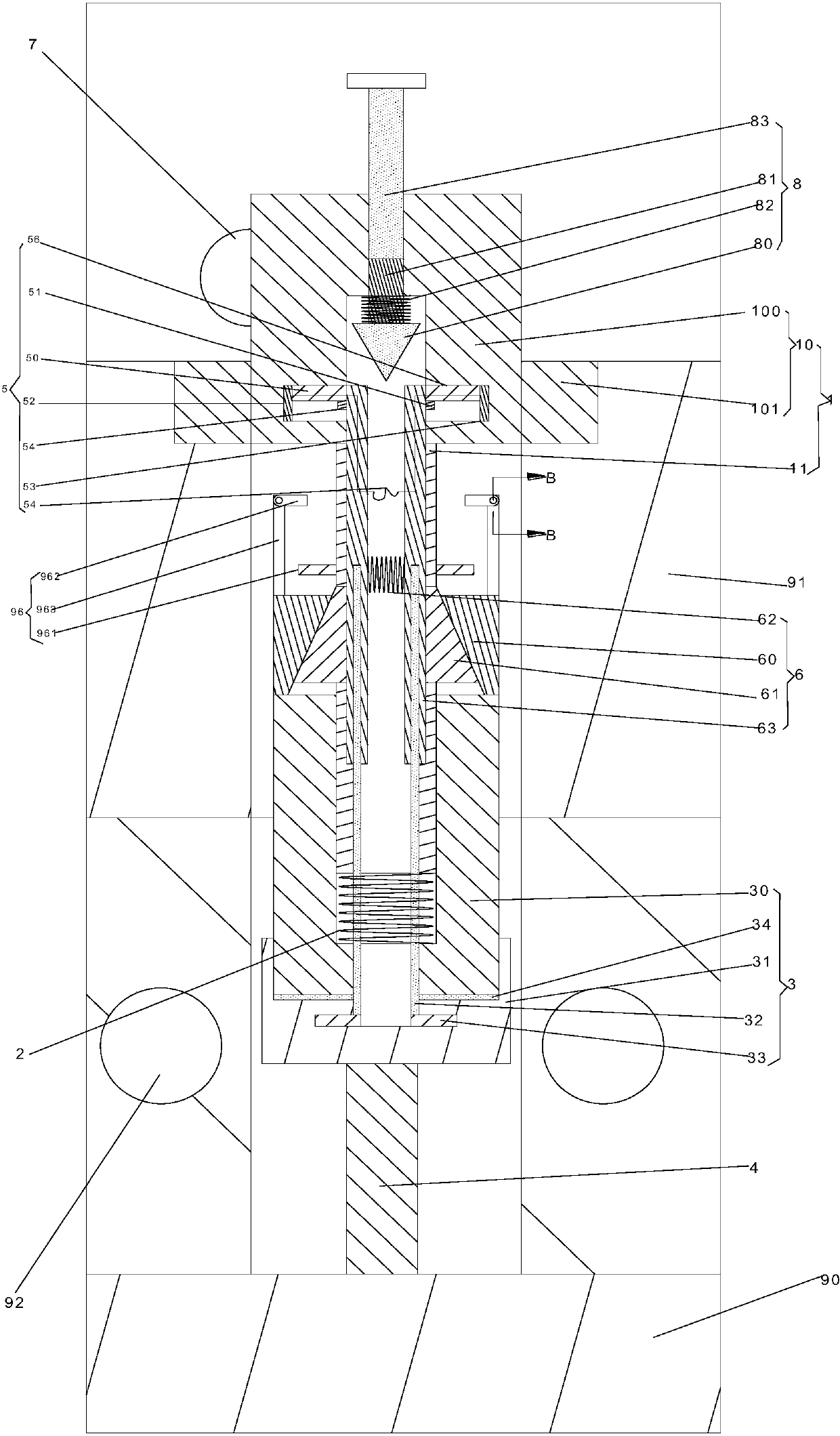

[0018] like figure 1 as well as figure 2 As shown, the present embodiment proposes a thermal fusion observation device, comprising: a mounting assembly 1, a first elastic member 2, a moving assembly 3, a thermal fusing block 4, a switch assembly 5, a driving assembly 6, a power supply (not shown in the figure) ) and the indicator light 7, the shell surface of the new stay cable HDPE waterproof cover is recessed to form a mounting hole, the installation hole is connected to the hot melt layer of the new stay cable HDPE waterproof cover, and the installation component 1 is connected to the mobile component through the first elastic member 2 3. After the mobile component 3 is connected with the installation component 1, it extends toward the hot melt layer. The end of the mobile component 3 close to the hot melt layer is equipped with a hot melt block 4, which can keep the hot melt block 4 and the The hot melt layer is close to each other, and there is a gap between the hot mel...

Embodiment 2

[0032] The difference between this embodiment and Embodiment 1 is that, in order to avoid the disengagement of the relative position between the installation rod 11 and the first wedge 60 due to the fact that the installation rod 11 has no pulling force on the first wedge 60 during disassembly, causing the snap-on arm 33 It cannot be separated from the mounting block 31 , so this embodiment only adds a limit assembly 96 on the basis of Embodiment 1.

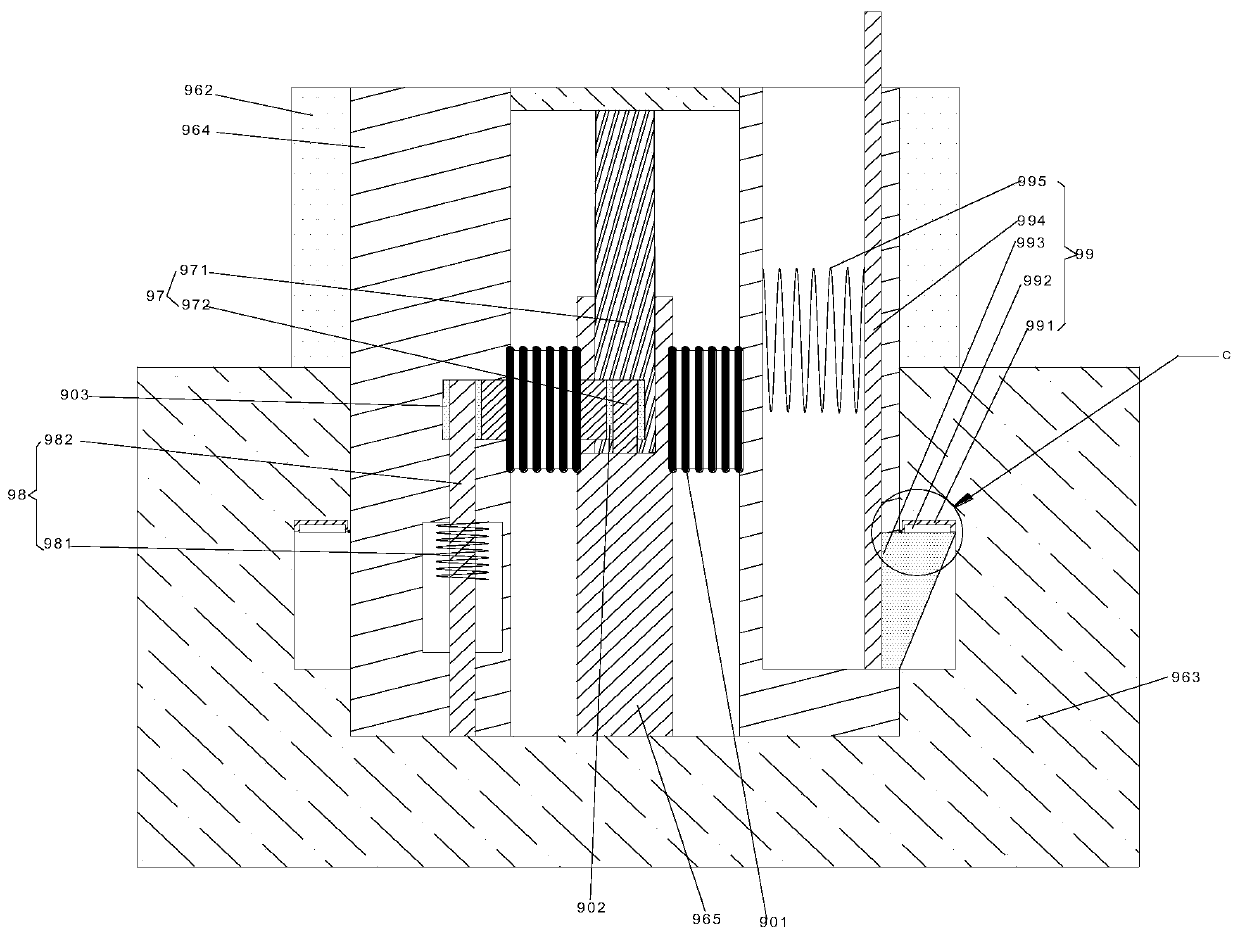

[0033] like Figure 3 to Figure 5 As shown, the thermal fusion observation device 95 further includes: a limiting component 96 . The limit assembly 96 includes: a second elastic member 960, a first limit arm 961, a second limit arm 962 and a mounting arm 963, and a wedge between the first wedge 60 and the mounting post 100 is mounted on the mounting rod 11. The first limiting arm 961 is provided with a second limiting arm 962 between the first limiting arm 961 and the mounting column 100, the second limiting arm 962 is hinged to...

Embodiment 3

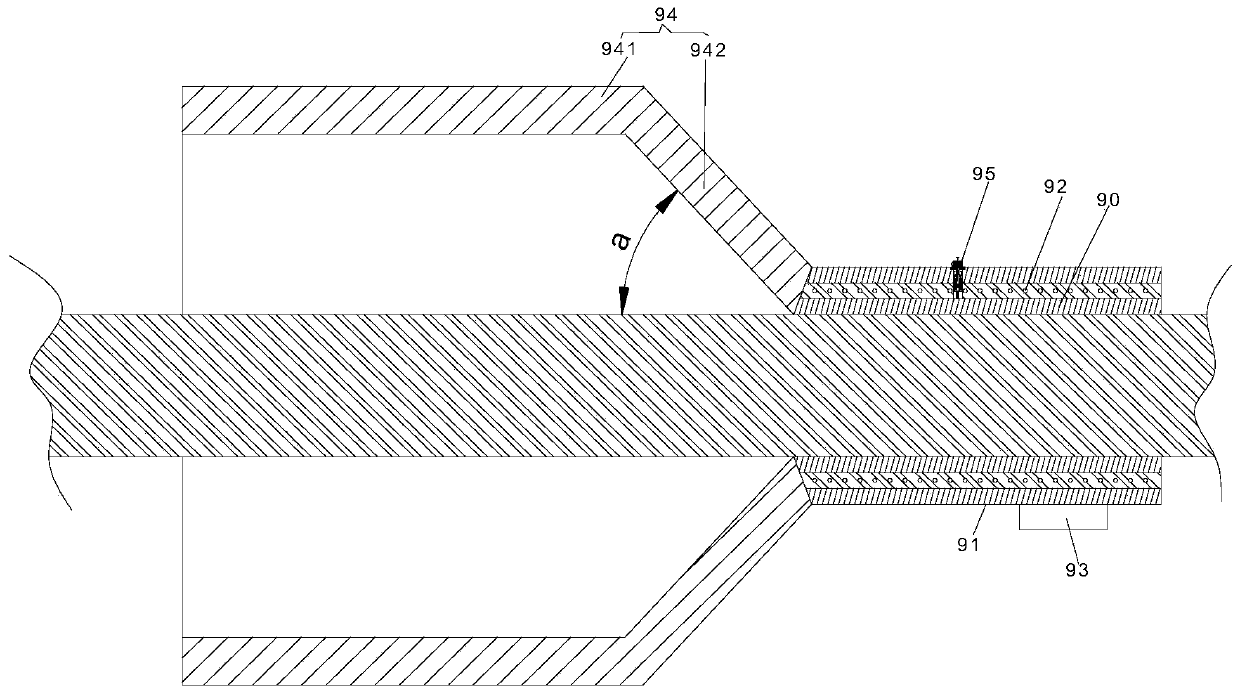

[0041] The present embodiment proposes a novel cable-stayed HDPE waterproof cover, comprising: a hot-melt layer 90, a housing 91, a resistance wire 92, an electrical socket 93, a cover body 94, and a hot-melt observation device as in Embodiment 1, and The molten layer surrounds the cable, the casing surrounds the hot-melt layer, and the electric socket is installed outside the casing. The resistance wire is embedded in the casing and surrounds the hot-melt layer. One end of the body is connected with a cover body, and the hot-melt observation device is installed on the shell body.

[0042] The specific structure of the thermal fusion observation device is as described in Example 1 or Example 2.

[0043] In order to facilitate drainage, the cover body 94 includes: an annular segment 941 and a truncated cone segment 942, the annular segment 941 and the truncated cone segment 942 are both sleeved outside the cable, and the annular segment 941 and the truncated cone segment 942 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com