A tamping machine capable of controlling steering

A technology of tamping machine and steering rod, which is used in soil protection, construction, infrastructure engineering and other directions, can solve the problems of inconvenient operation, complex structure, low tamping efficiency, etc., and achieve the effect of easy direction control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

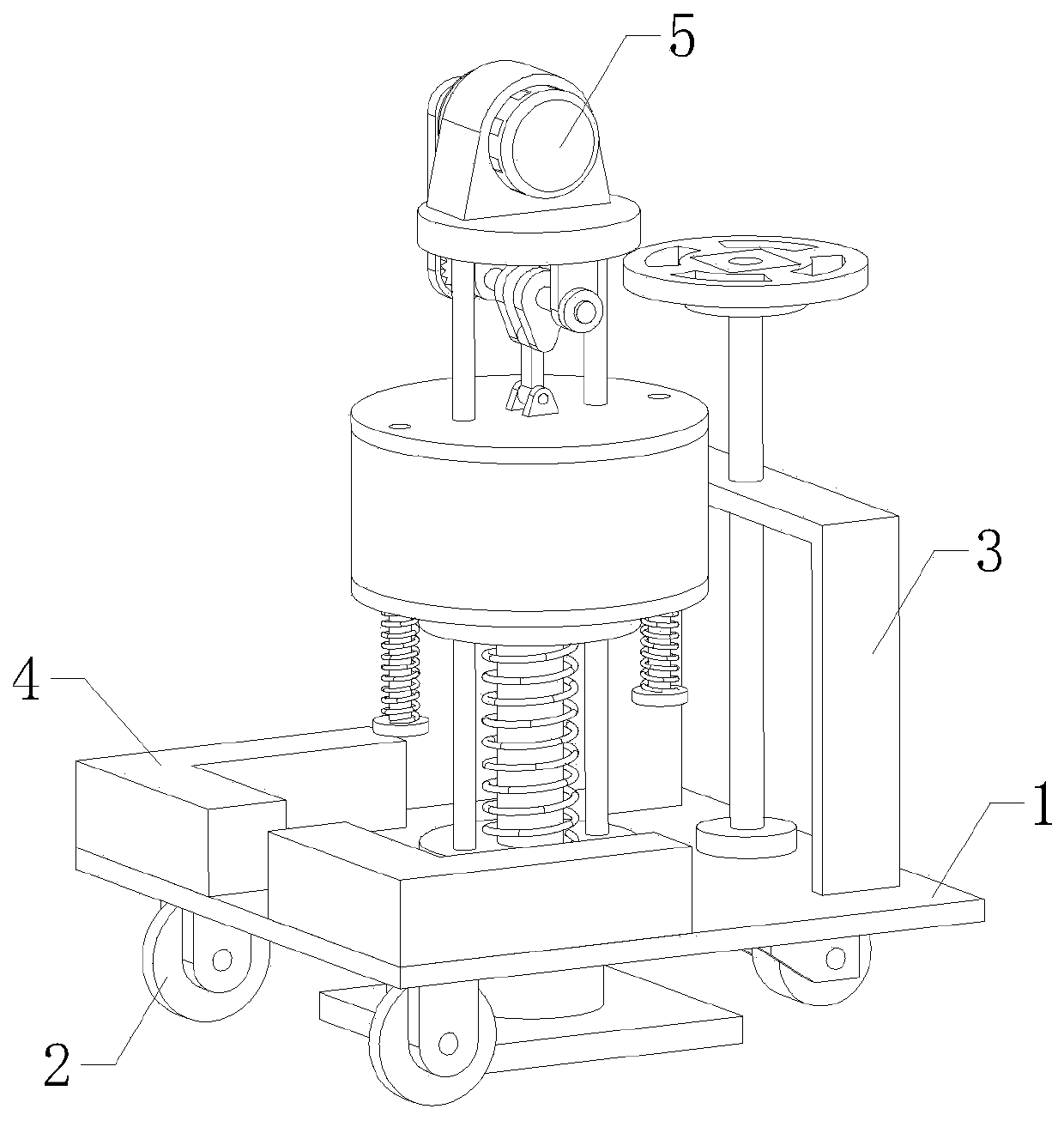

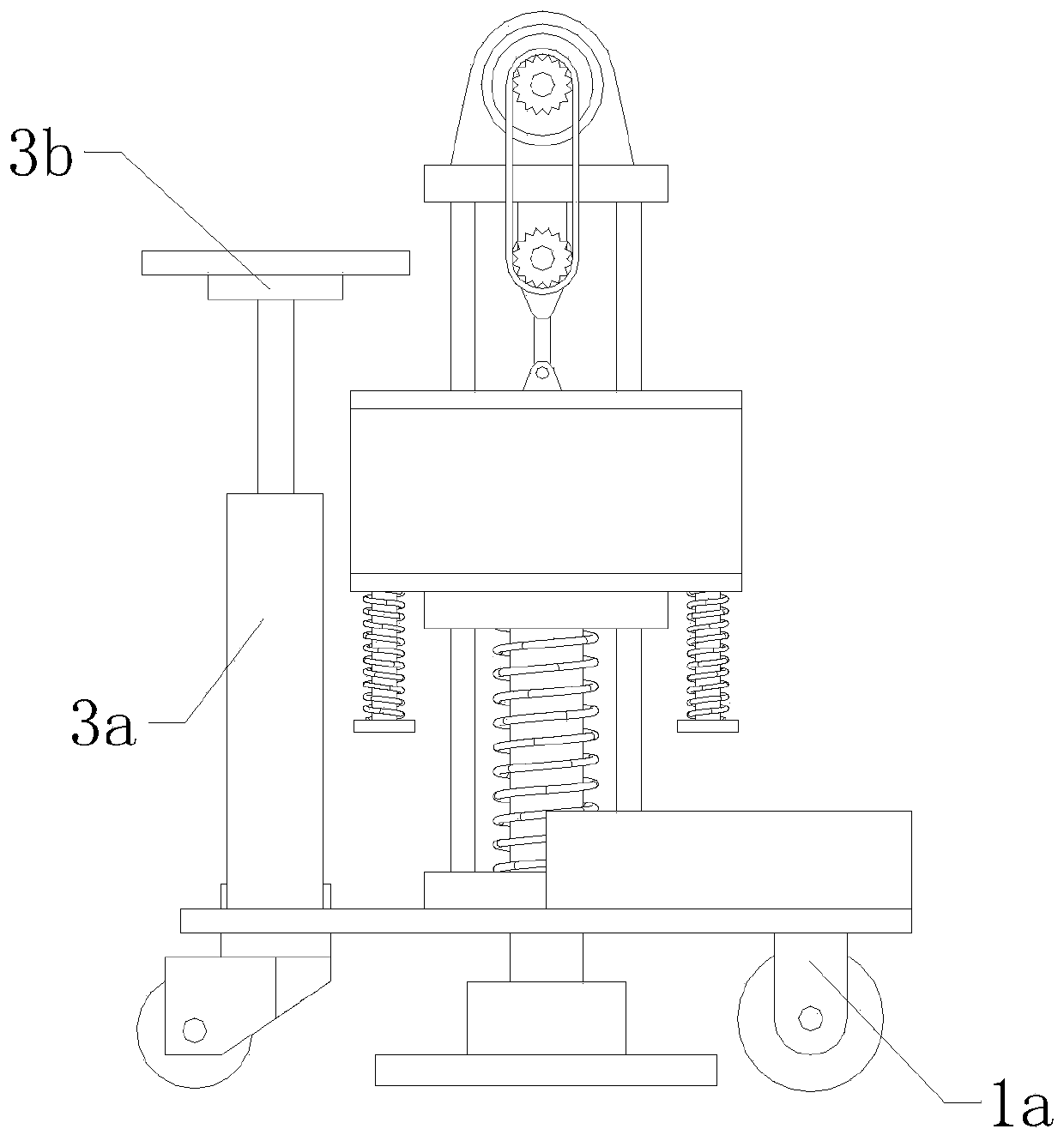

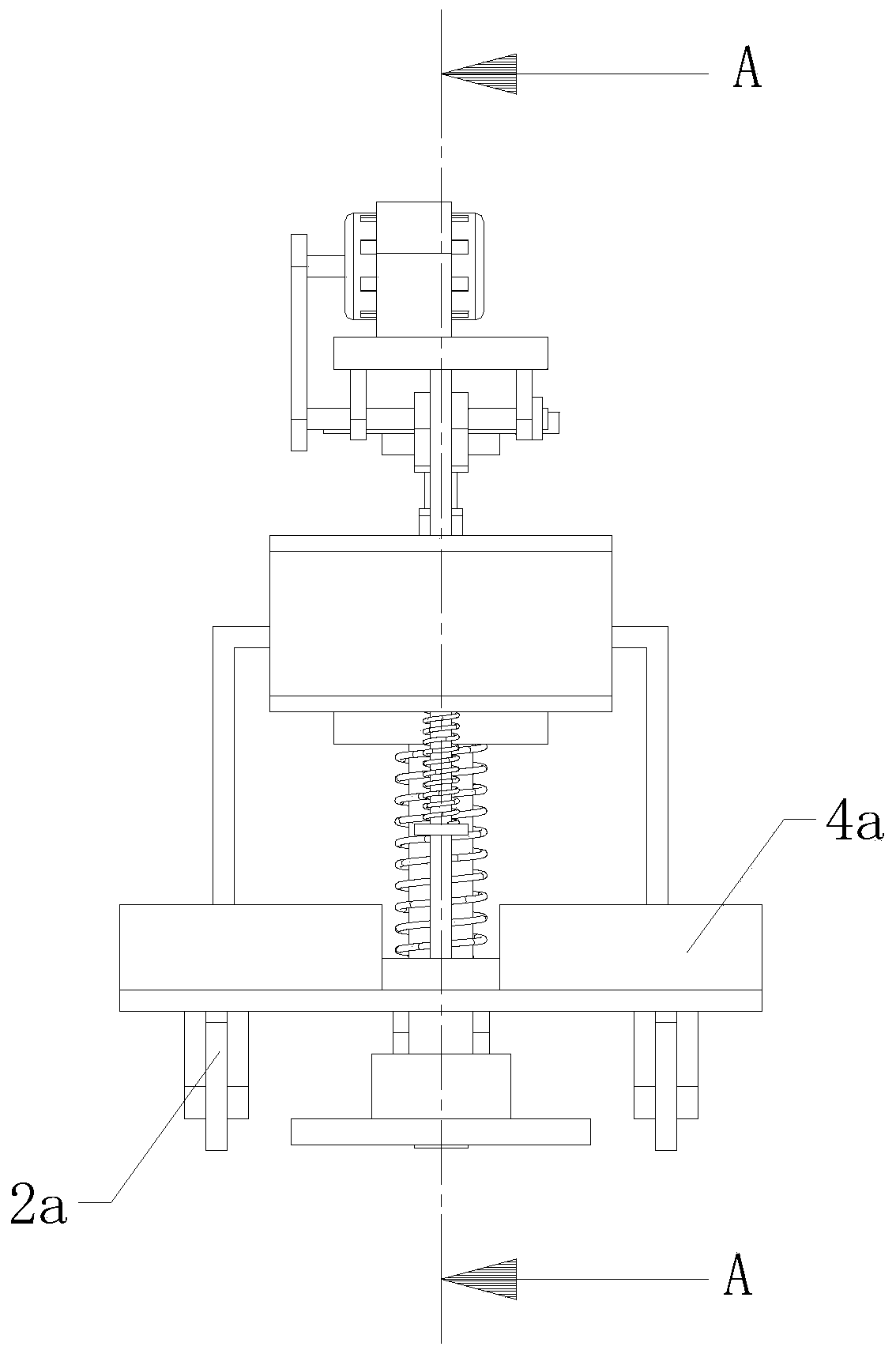

[0025] refer to Figure 1 to Figure 11 A tamping machine that can control steering is shown, including a chassis 1, a rolling device 2 arranged at the bottom of the chassis 1, a steering device 3 arranged at the top of the chassis 1, a balancing device 4 arranged at the top of the chassis 1 and a 1 Tamping device 5 on top.

[0026] The rolling device 2 includes a rolling assembly 2a, the rolling assembly 2a is rotatably arranged on the bottom of the chassis 1, the steering device 3 includes a supporting assembly 3a and a steering assembly 3b, and the supporting assembly 3a is fixedly arranged on the bottom of the chassis 1 At the top, the steering assembly 3b is rotatably arranged on the support assembly 3a and is plugged with the chassis 1. The balance device 4 includes a balance assembly 4a, and the balance assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com