Ceramic integrated wall board close-joint installation structure used for flat wall surface

A technology for integrating wall panels and installation structures, which is applied in building construction, covering/lining, construction, etc., and can solve problems such as increased construction procedures, easy loosening of decorative parts, and material waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

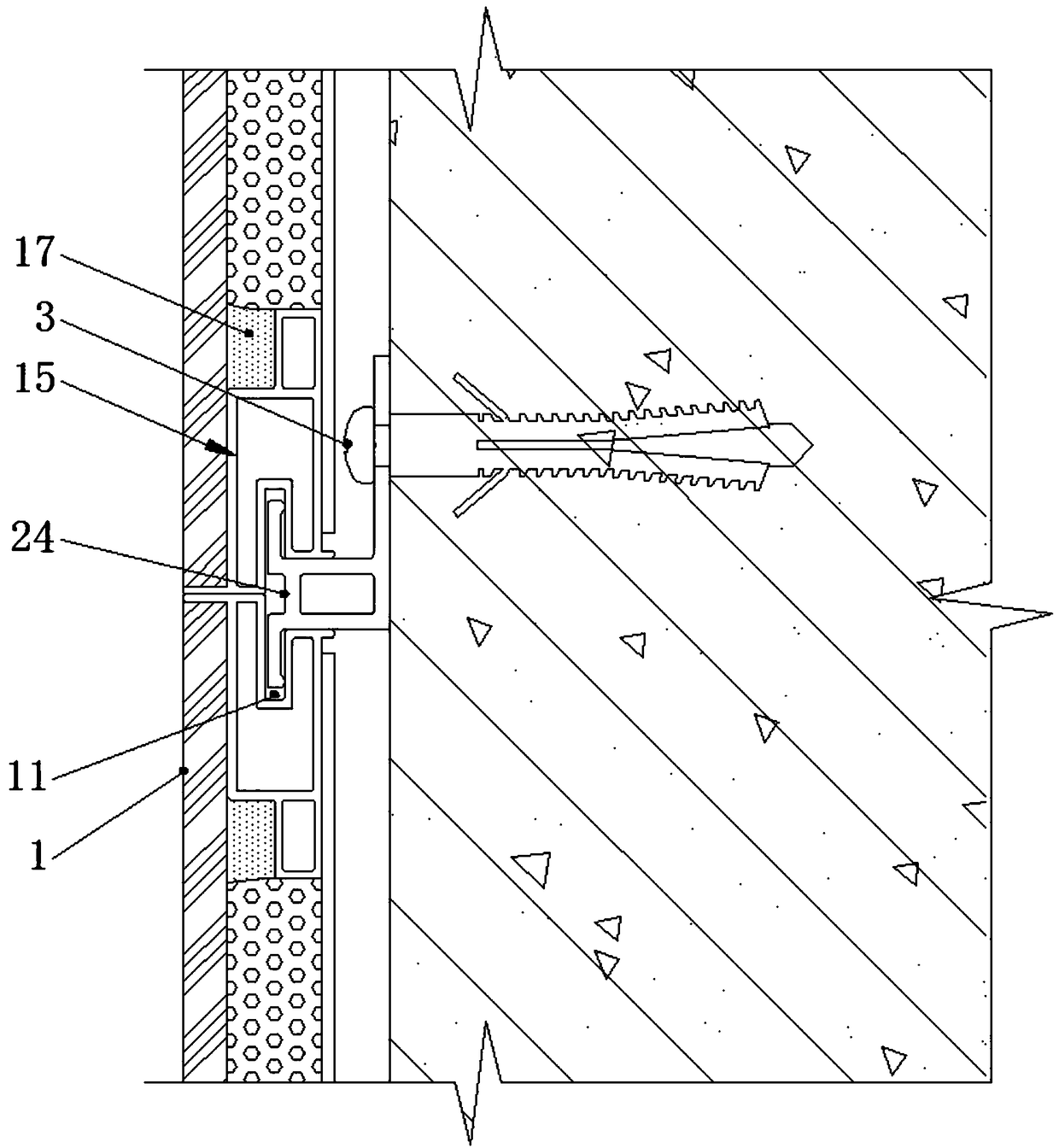

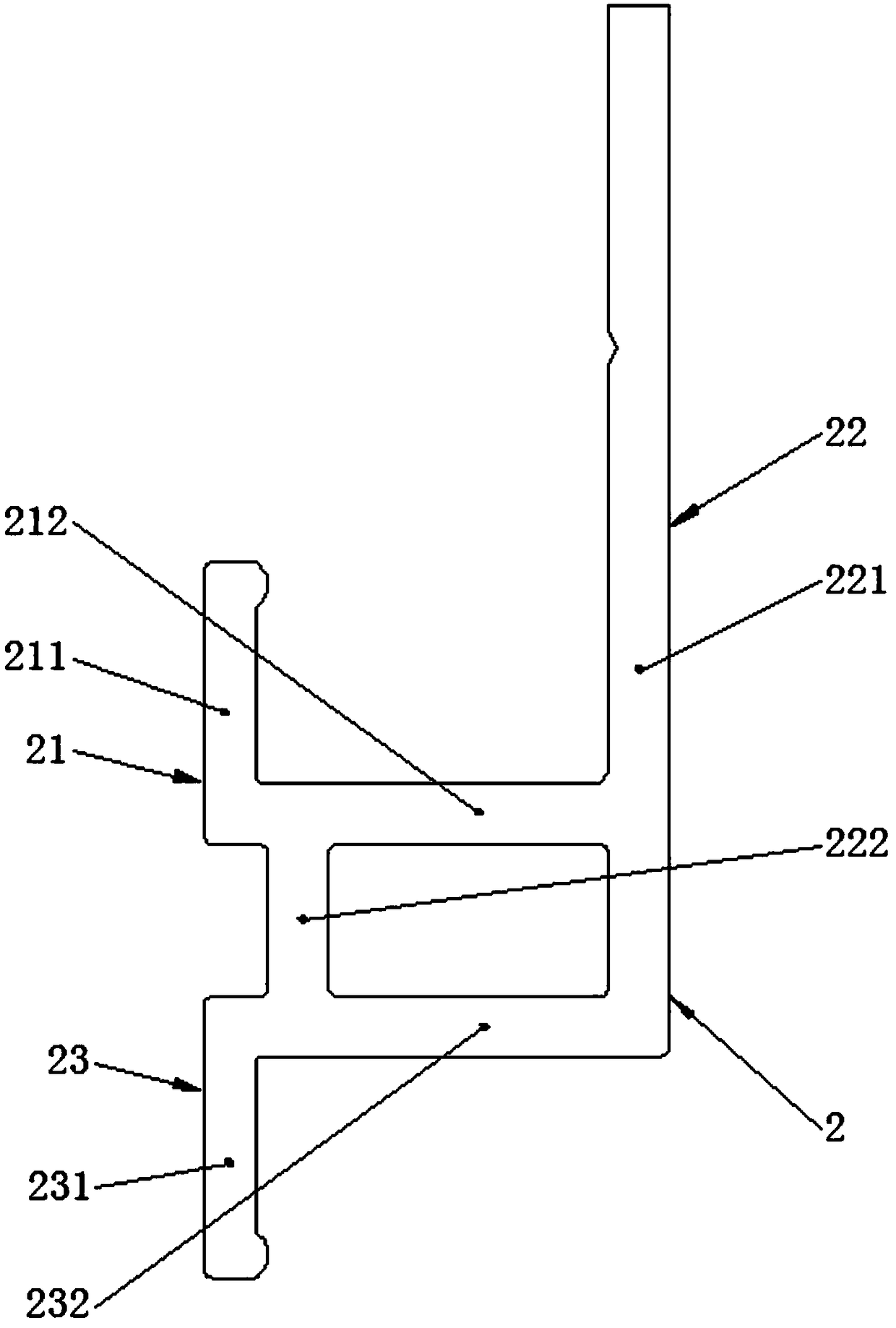

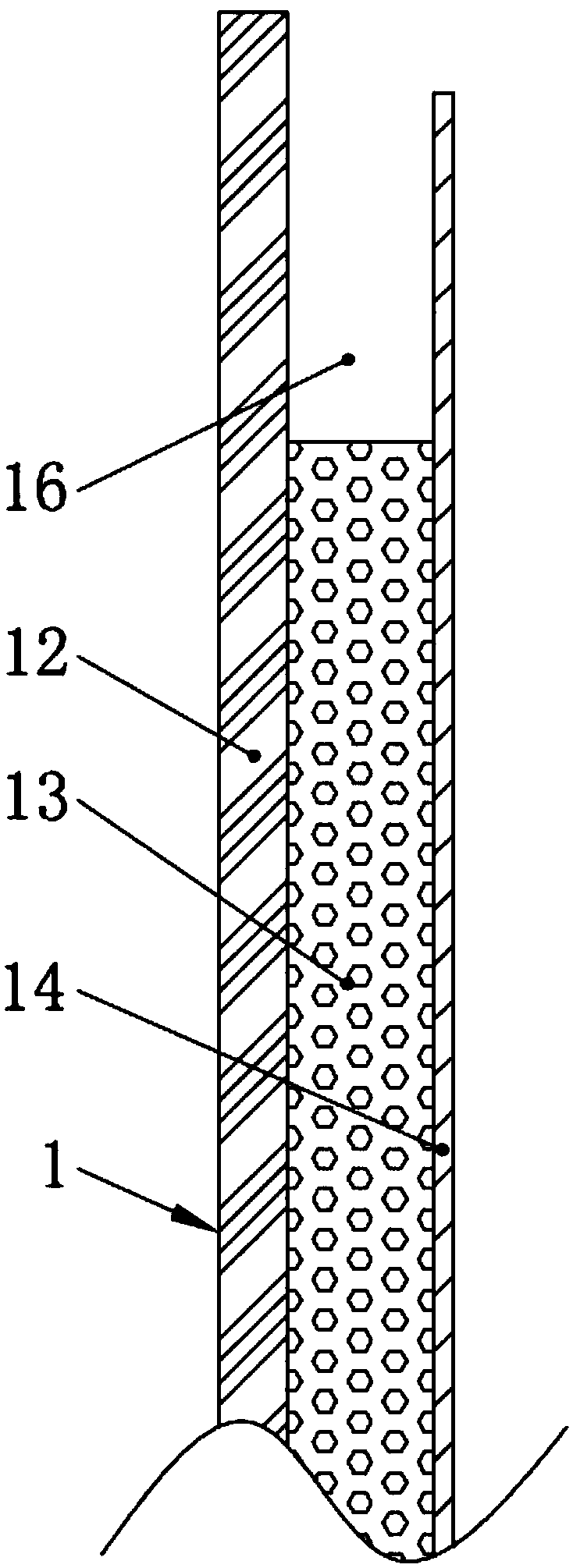

[0024] A kind of ceramic integrated wall panel sealing seam installation structure that is used for flat wall surface of this embodiment, such as figure 1 and figure 2 As shown, it includes a ceramic integrated wallboard 1, a mounting part 2 and an expansion bolt 3. There are multiple ceramic integrated wallboards 1, and each of the ceramic integrated wallboards 1 is provided with a mounting groove 11 on the end surface around it. The length and width of the left surface of each said ceramic integrated wallboard 1 are respectively greater than the length and width of its right surface; said mounting parts 2 are multiple, and each said mounting part 2 includes an upper connection part 21, a middle connection part 22 and the lower connecting part 23, the middle connecting part 22 includes a first co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap