Wall building robot

A technology of wall-building robots and mechanical claws, applied in manipulators, manufacturing tools, construction, etc., can solve the problems of large bricks, large quantities, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

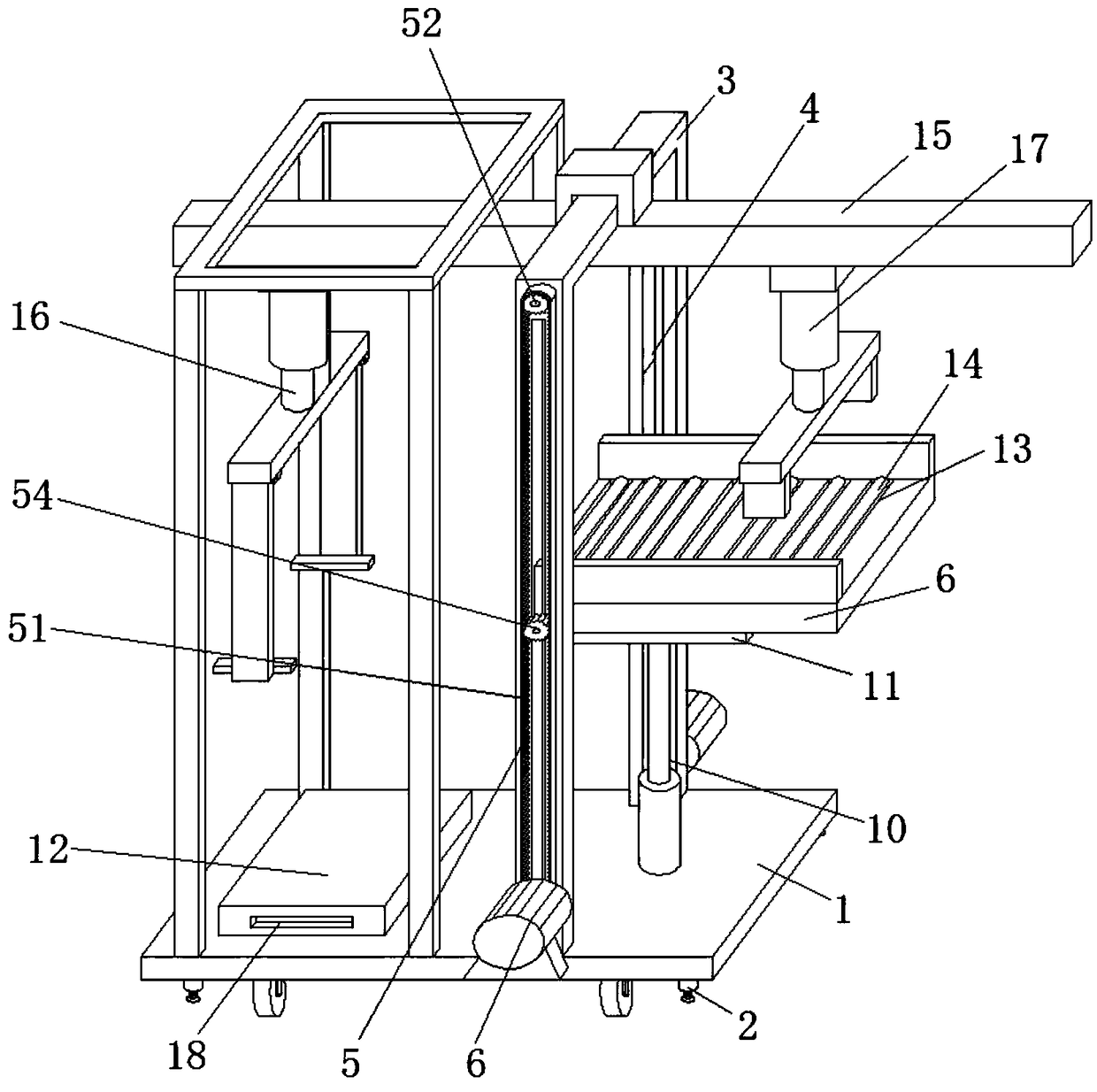

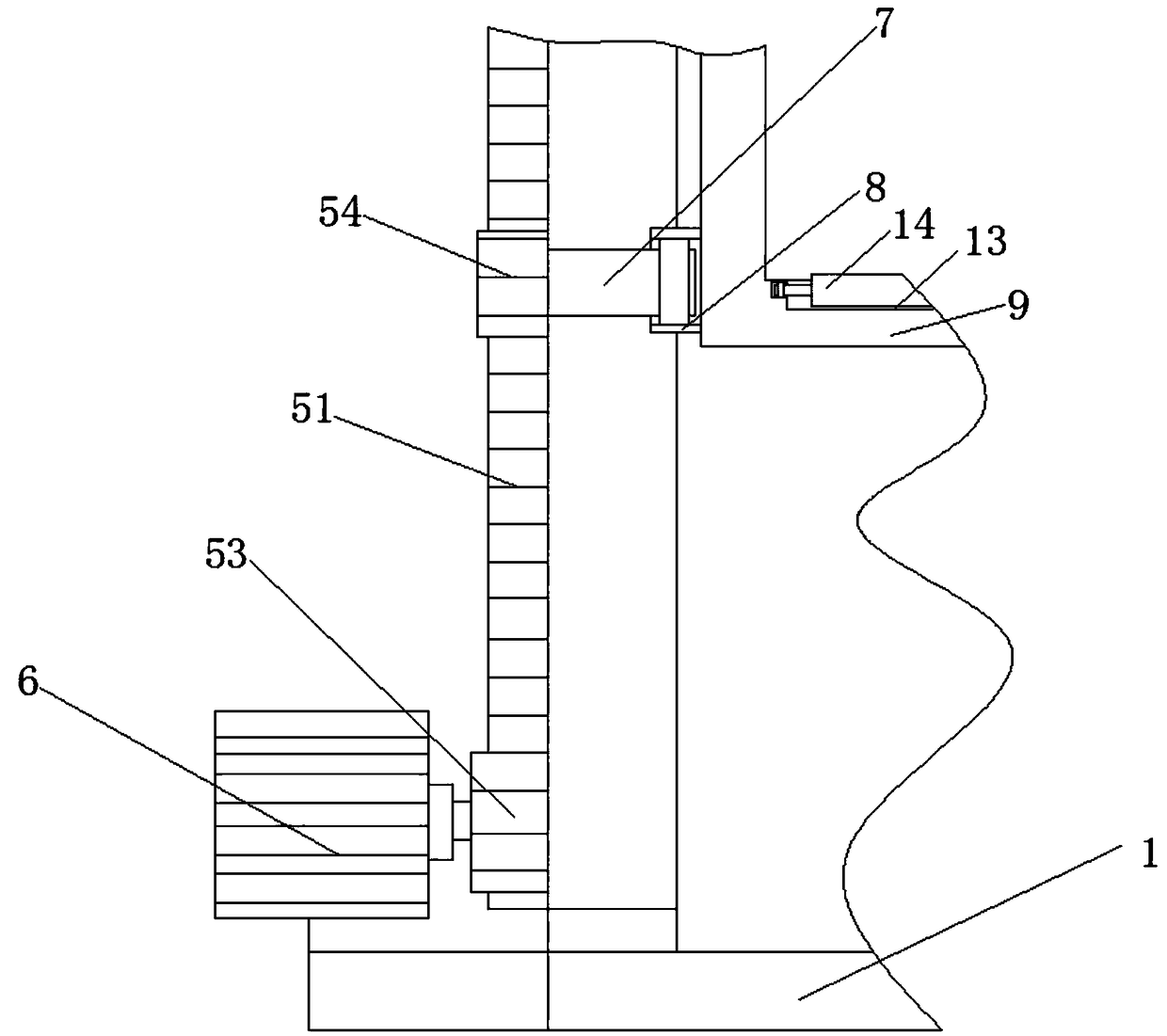

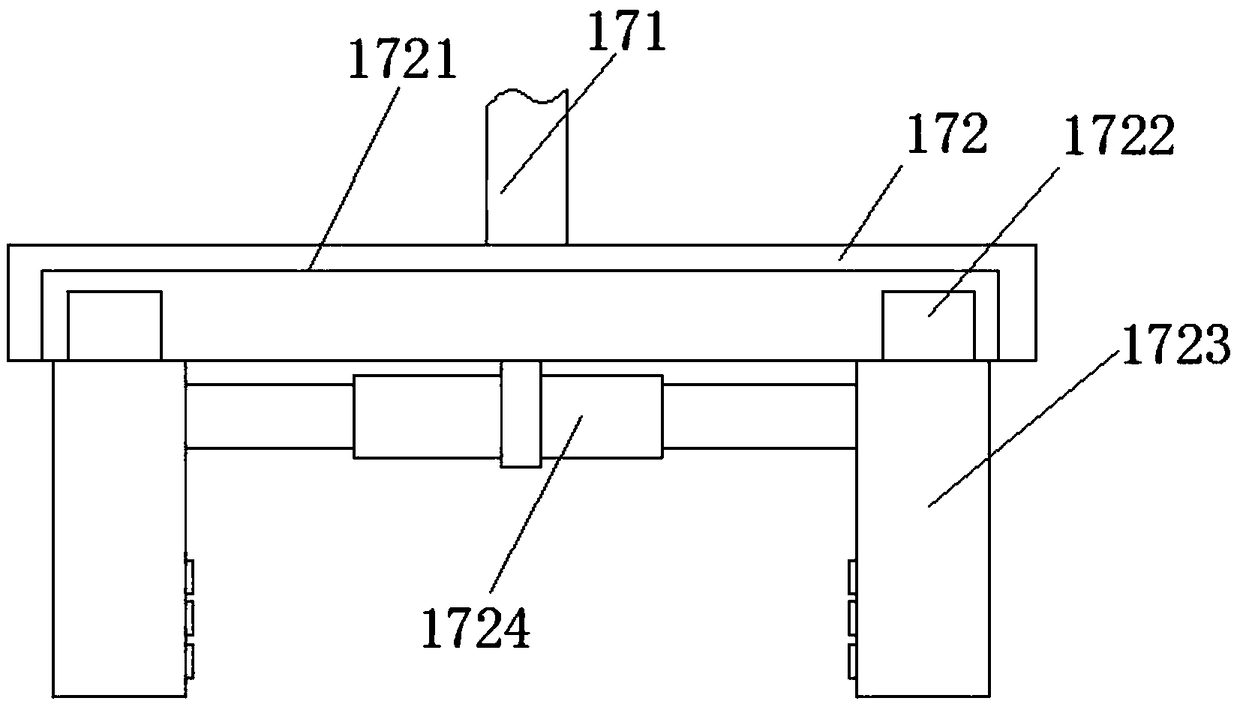

[0022] see Figure 1-2 , the present embodiment provides a wall-building robot, comprising a bottom plate 1, the top of the bottom plate 1 is fixedly connected with a fixed frame 3, and both sides of the inner wall of the fixed frame 3 are provided with moving ports 4, and both sides of the fixed frame 3 are provided with There is a transmission assembly 5, one side of the transmission assembly 5 is provided with a motor 6, the inner wall of the moving port 4 is slidingly connected with a rotating shaft 7, one side of the rotating shaft 7 is rotatingly connected with a rotating seat 8, and one side of the rotating seat 8 is fixedly connected with a brick Platform 9, the top of base plate 1 is fixedly equipped with cylinder 10, and the top of cylinder 10 is fixedly connected with support plate 11, and support plate 11 is movably connected with brick setting platform 9. The top of base plate 1 is movably connected with brick plate 12, fixed frame 3 Inner wall top is fixedly conn...

Embodiment 2

[0025] see Figure 1-2 , made further improvement on the basis of Embodiment 1: the transmission assembly 5 includes a gear belt 51, an upper positioning gear 52 and a lower positioning gear 53, the lower positioning gear 53 is fixedly connected with the output shaft of the motor 6, and the inner wall of the gear belt 51 The connecting gear 54 is meshed, and the connecting gear 54 is fixedly connected with the rotating shaft 7. When carrying out the lifting of the brick table 9, the positioning gear 53 is driven by the motor 6 to rotate, so that the gear belt 51 is rotated, and the gear belt 51 drives the connecting gear 54 to rotate. The internal movement of the gear belt 51 enables the rotating shaft 7 to move in the vertical direction, wherein the moving port 4 can well limit the rotating shaft 7 to prevent it from shifting.

[0026] Wherein, the bottom of the bottom plate 1 is movably connected with a moving wheel, and the bottom of the bottom plate 1 is fixedly connected ...

Embodiment 3

[0028] see Figure 1-2 , on the basis of Embodiment 1, a further improvement has been made: the inner wall of the rotating seat 8 is provided with a bearing, and the rotating shaft 7 is socketed with the inner edge of the bearing, so that the rotating shaft 7 can rotate more smoothly, so that the connecting gear 54 can rotate more smoothly , the top of the brick platform 9 is provided with a mounting groove 13, the inner wall of the mounting groove 13 is rotatably connected with a running wheel 14, and the surface of the rotating wheel 14 is provided with a rubber sleeve, by setting the rotating wheel 14, it is convenient for the follow-up brick plate 12 The used brick plate 12 is extruded from the brick platform 9 to prevent material accumulation on the brick platform 9.

[0029] Wherein, the upper brick mechanical claw 16 includes a driving cylinder and a brick claw, and the inner wall of the brick claw is provided with a block, and both sides of the brick plate 12 are provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com