Open pit coal mine dumping method

An open-pit coal mine and soil dumping technology, which is applied in open-pit mine mining, earth square drilling, special mining, etc., can solve the problem of low efficiency of soil dumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

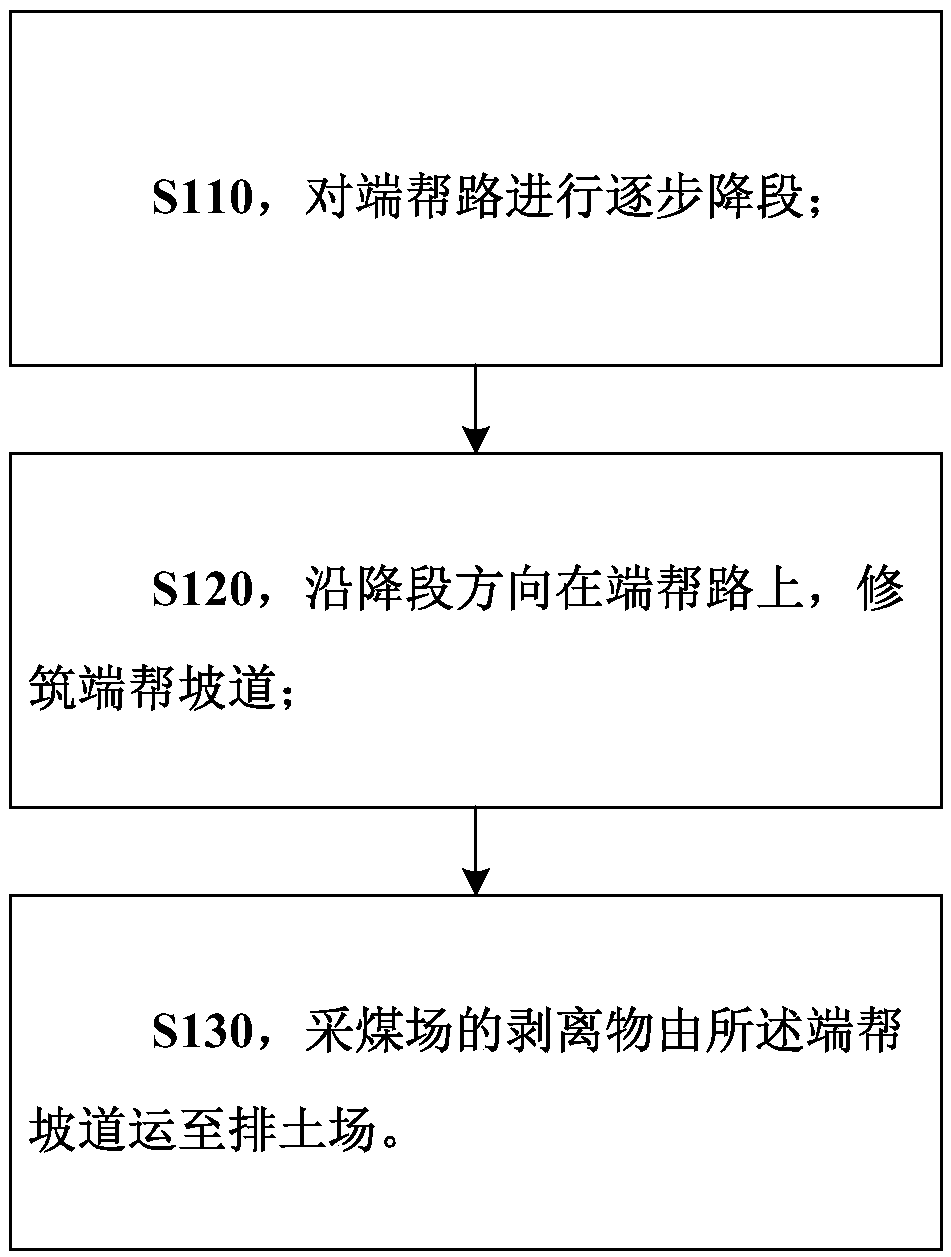

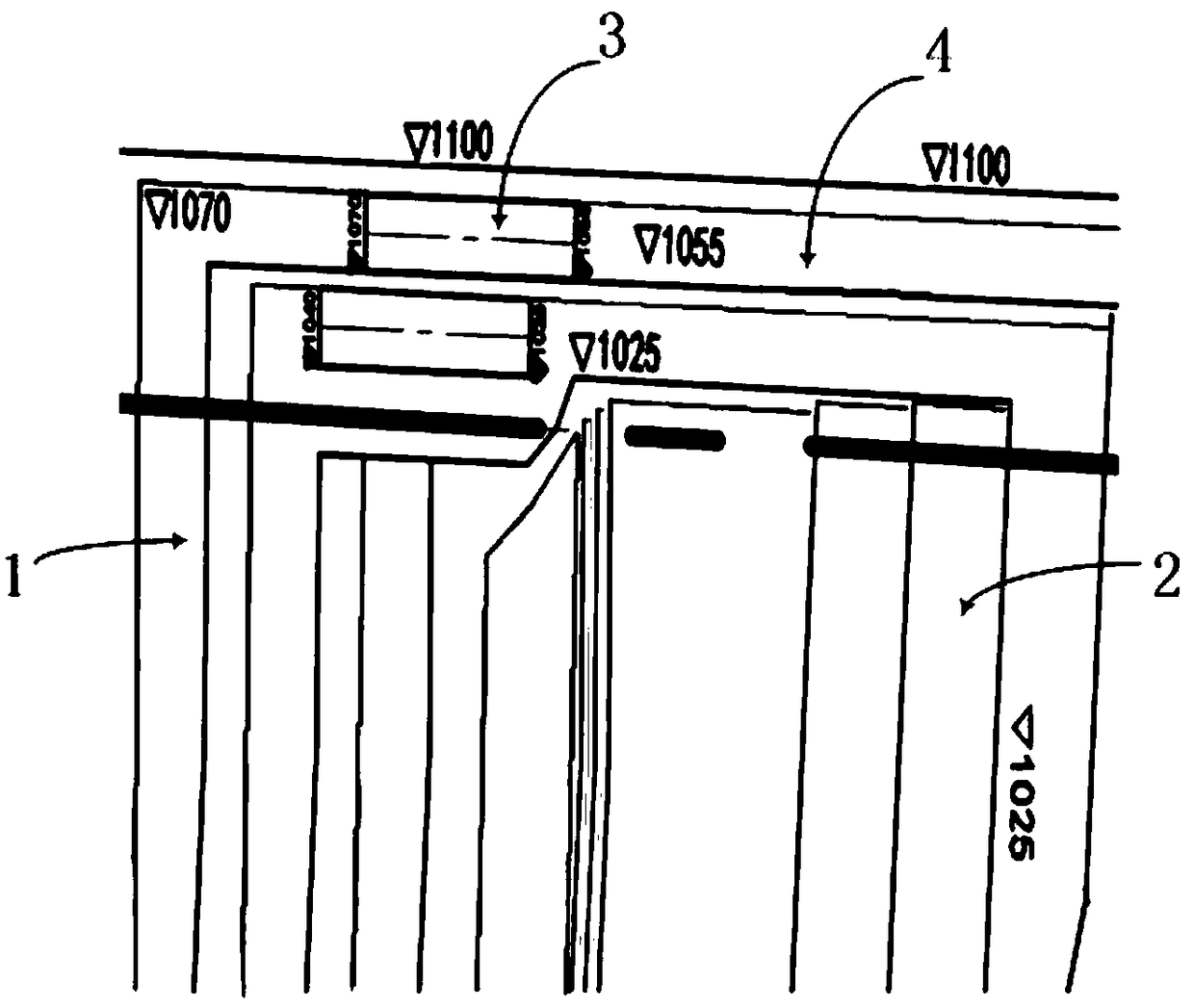

[0021] figure 1 Shows the flow chart of the open-pit coal mine dumping method of the embodiment of the present invention, figure 2 A schematic diagram of the location of the solid square end-side ramp is shown. Such as figure 1 and 2 As shown, the open-pit coal mine dumping method that the embodiment of the present invention provides, it comprises:

[0022] S110, step down the Duanbang Road step by step;

[0023] Duanbang Road 4 and dump site 1 are at the same level. One end of Duanbang Road 4 is connected to dump site 1, and the other end is gradually descended to connect with coal mining site 2.

[0024] Duanbang Road 4 is gradually degraded to form a first-level Duanbang Road, a second-level Duanbang Road...N-level Duanbang Road, where N≥2. The height of the N-level end side road is consistent with the height of the coal mining field.

[0025] S120, along the direction of the descending section, build a ramp on Duanbang Road;

[0026] Secondary end-side ramps can b...

Embodiment 2

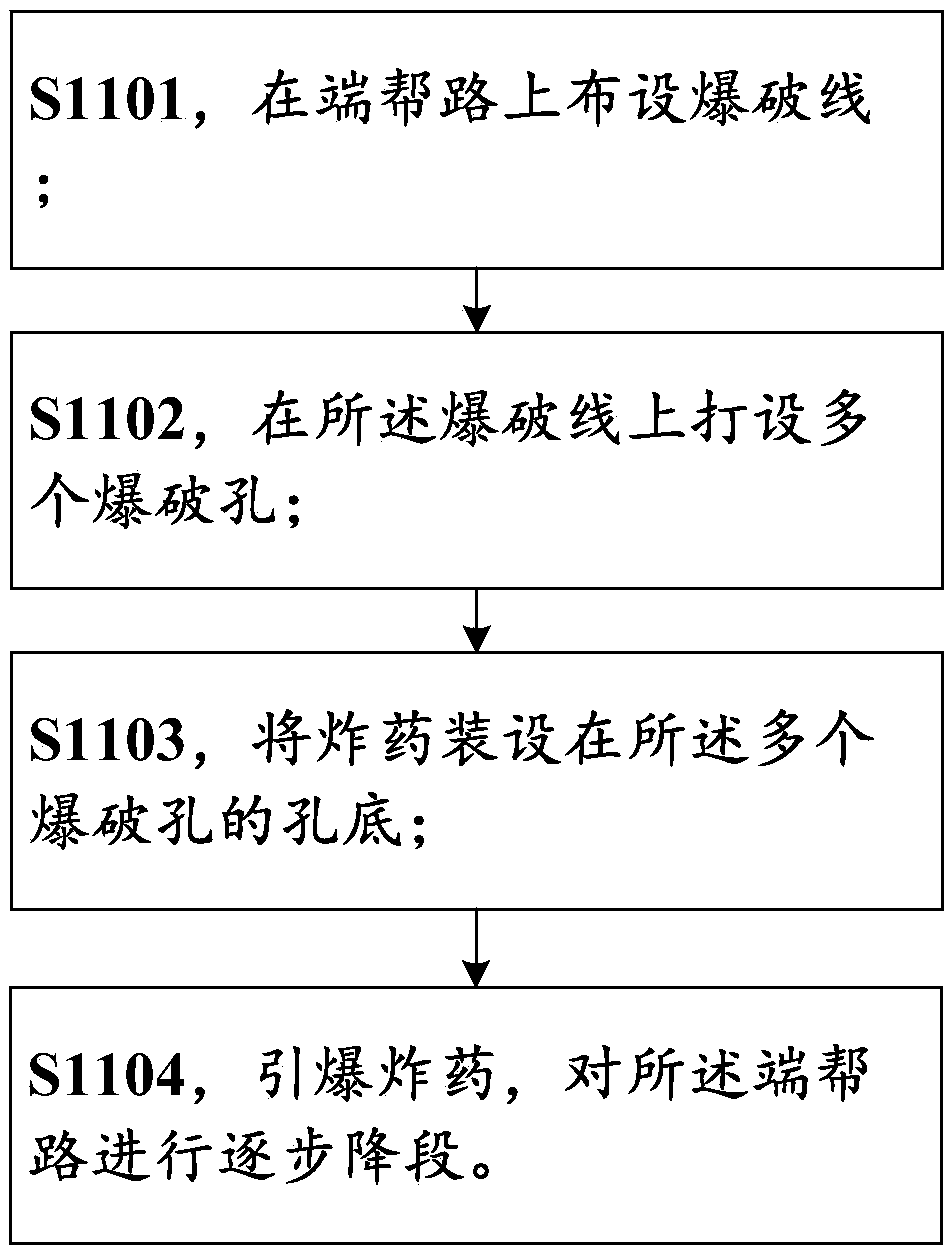

[0037] On the basis of the first embodiment above, optionally, as image 3 As shown, S110, gradually descending the end-side road, specifically including:

[0038] S1101, laying blasting lines on Duanbang Road;

[0039] The blasting line can be arranged along the length direction of the end side road 4, and can also be arranged along the width direction of the end side road 4.

[0040] S1102, drilling a plurality of blast holes on the blast line;

[0041] A plurality of blast holes can be evenly arranged along the blast line to facilitate the arrangement of blast holes. In this embodiment, the distance between adjacent blast holes is about 6 meters.

[0042] S1103, installing explosives at the bottom of the plurality of blast holes;

[0043] Bury explosives at the bottom of each blast hole.

[0044] S1104, detonate the explosives, and gradually descend the section of the end-side road.

[0045] Carry out loosening blasting on the end side road 4, and change the solid end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com