A wind turbine generator bearing automatic lubrication intelligent control system and method

An intelligent control system and generator bearing technology, applied in the control of wind turbines, wind power generation, machines/engines, etc., can solve problems such as blocked grease discharge channels, bearing high temperature alarms, rough lubrication strategies, etc., to improve reliability , Reduce maintenance costs and save workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

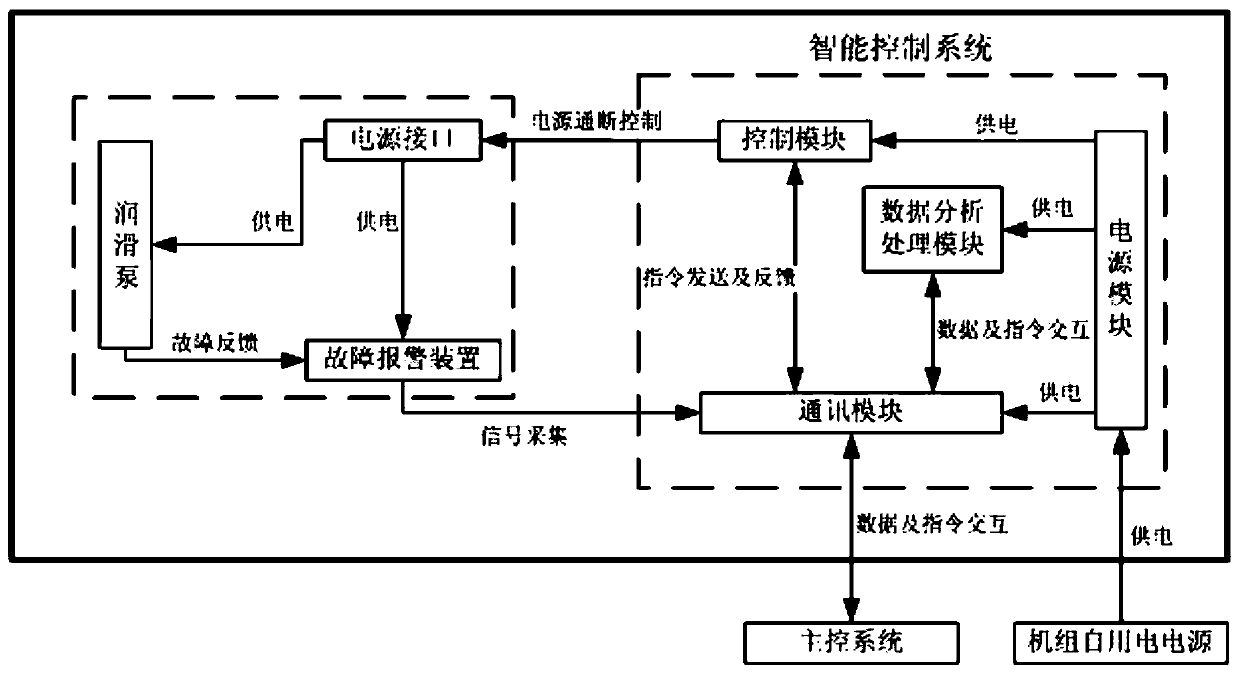

[0027] Refer to attached figure 1 As shown, the wind turbine generator bearing automatic lubrication intelligent control system of the present invention includes a lubrication pump and an intelligent control subsystem.

[0028] In this embodiment, the lubricating pump adopts a mechanical lubricating pump without a control system. The mechanical lubricating pump includes a grease injection port, a grease injection pipe, a drive motor, a grease storage chamber and a fault sensor. The failure sensors include a low fuel level alarm sensor and / or a clogging alarm sensor. This embodiment also includes a fault alarm device connected to the low oil level alarm sensor and / or blockage alarm sensor, and the fault alarm device is connected to the communication module in the intelligent control system. Then the fault alarm device realizes the alarm by receiving the fault information collected by the fault sensor, and transmits the collected fault information to the main control system of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com