Oxygen-rich fan

An oxygen-enriched fan and oxygen-enriched technology, applied in gas treatment, liquid fuel engines, mechanical equipment, etc., can solve problems such as discomfort symptoms, achieve the effect of improving user comfort, improving breathing comfort, and avoiding physical discomfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

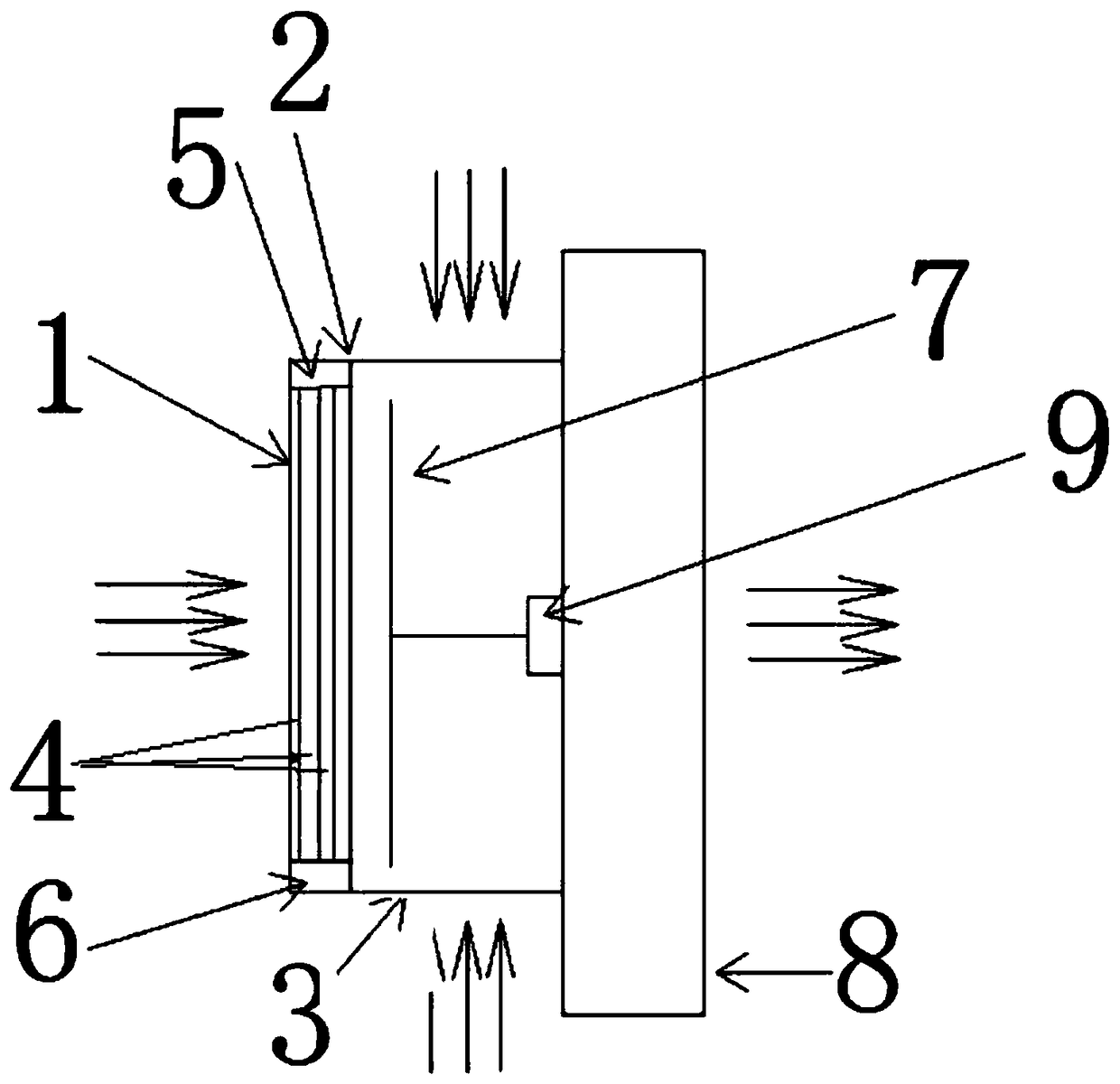

Embodiment 1

[0028] Such as figure 1 As shown, an oxygen-enriched fan of the present invention includes a fan body, and an oxygen-enriched module arranged on the fan body, and the oxygen-enriched module is arranged inside at least one air inlet surface of the fan body , the air inlet surface provided with the oxygen-enriched module is an oxygen-enriched air inlet surface, the oxygen-enriched module has an air inlet side, an air outlet side, and an exhaust gas outlet, and the air inlet side is connected to the corresponding oxygen-enriched air inlet The air inlet on the air side communicates, the air outlet side communicates with the inside of the fan body, the exhaust gas outlet communicates with the outside of the fan body, and the air passes through the oxygen-enriched module from the inlet side to separate oxygen from the The gas outlet side flows out, and the remaining gas flows out from the exhaust gas outlet.

[0029] At least one air inlet surface of the fan body is set as an oxyge...

Embodiment 2

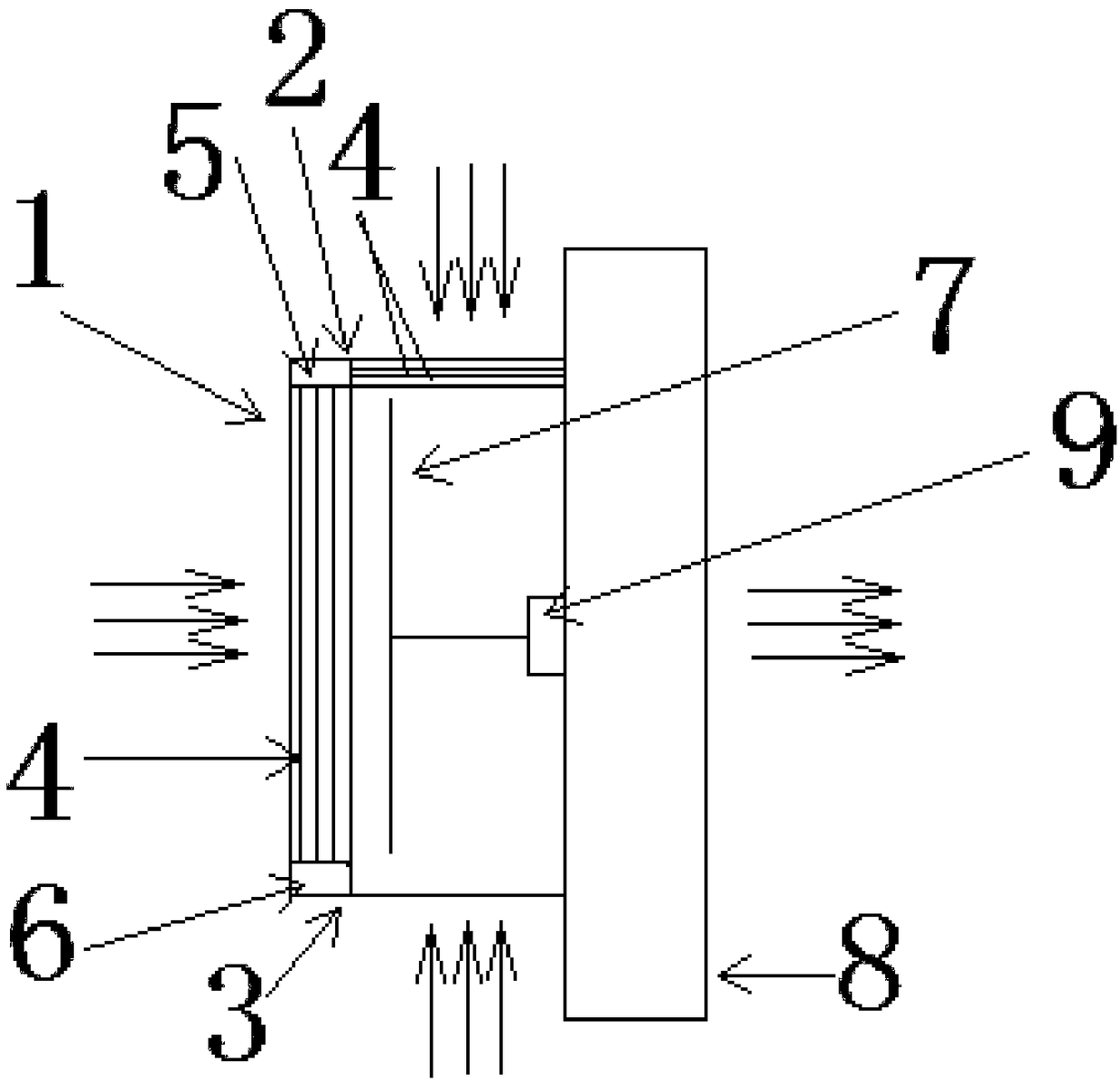

[0037] Such as figure 2 As shown, the difference between Embodiment 2 and Embodiment 1 is that a common waste gas outlet is provided at the junction of the air inlet side wall and the air inlet bottom, and the common exhaust gas outlet is the air inlet side. The oxygen enrichment module on the wall is shared with the oxygen enrichment module on the bottom of the air intake. This can make the structure of the oxygen-enriched fan more compact and occupy less space.

[0038]In this embodiment, preferably, the air inlet side walls include upper and lower air inlet side walls, and left and right air inlet side walls, and the air inlet bottom 1 and the upper air inlet side wall 2 are respectively provided with the oxygen-enriched module, where the upper end of the air inlet bottom 1 and the upper air inlet side wall 3 meet to form an upper common exhaust gas outlet, of course, as one of the alternative implementations, it can also be the upper air inlet bottom 1, The upper air in...

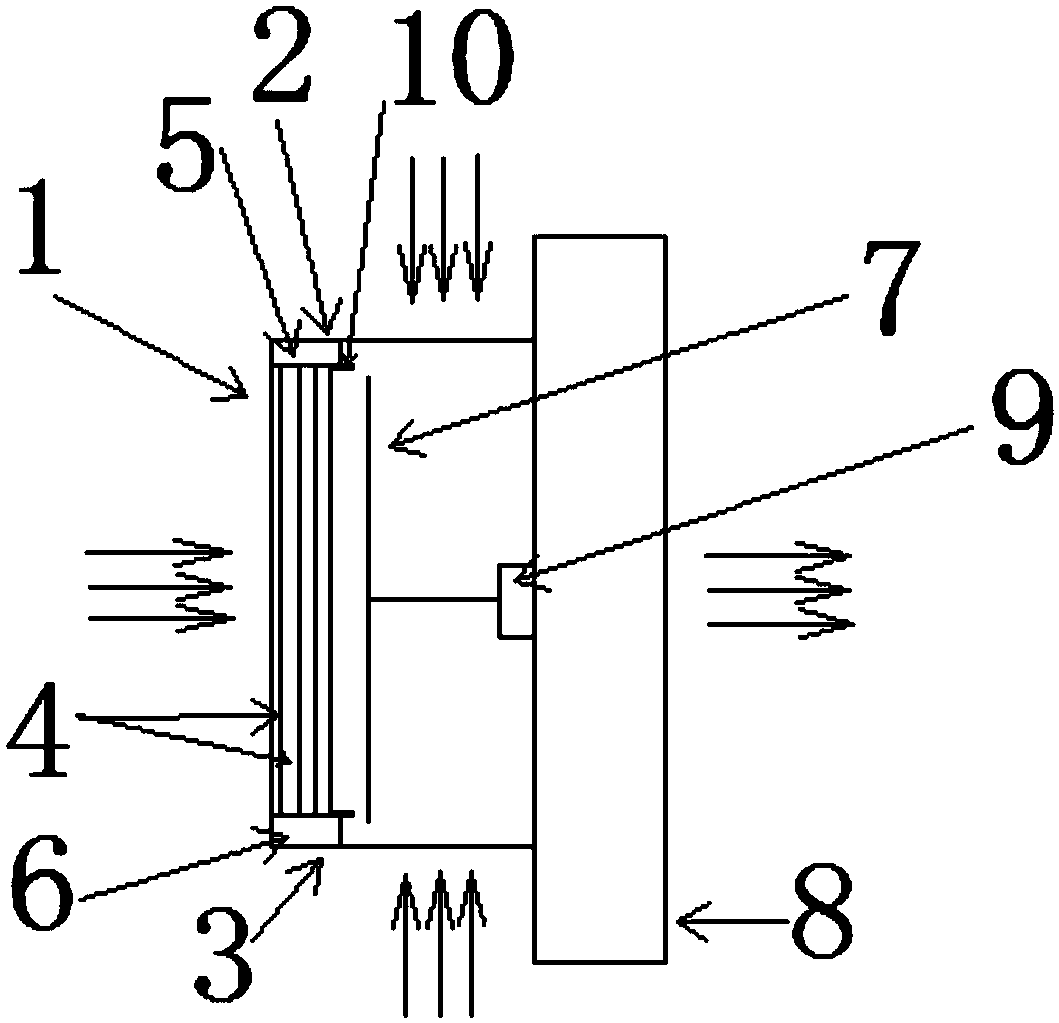

Embodiment 3

[0040] Such as image 3 As shown, the difference between Embodiment 3 and Embodiment 1 or 2 is that the oxygen-enriched module also includes an adjustment slide cover 10, and the adjustment slide cover 10 is arranged at the exhaust gas outlet facing the multi-layer oxygen-enrichment module. One side of the membrane 4, and can slide along the lamination direction of the multi-layer oxygen-enriched membrane 4, and is used to block the part of the exhaust gas outlet that is not provided with the oxygen-enriched membrane 4. In this way, the number of layers of the oxygen-enriched membrane 4 in the oxygen-enriched module can be increased or decreased according to the actual use, so as to realize the adjustment of the oxygen content in the air blown by the fan. Further, preferably, the adjusting sliding cover 10 is detachably arranged on the housing of the oxygen-enriching module. During specific operation, the adjusting slide cover 10 can be removed from the oxygen-enriched module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com