Valve rod valve rotating device

A technology of rotating devices and valves, which is applied in the direction of valve devices, valve operation/release devices, valve details, etc., can solve the problems of increasing production costs of enterprises and increasing capital investment of rotating equipment, so as to reduce production costs of enterprises and improve compatibility of use sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

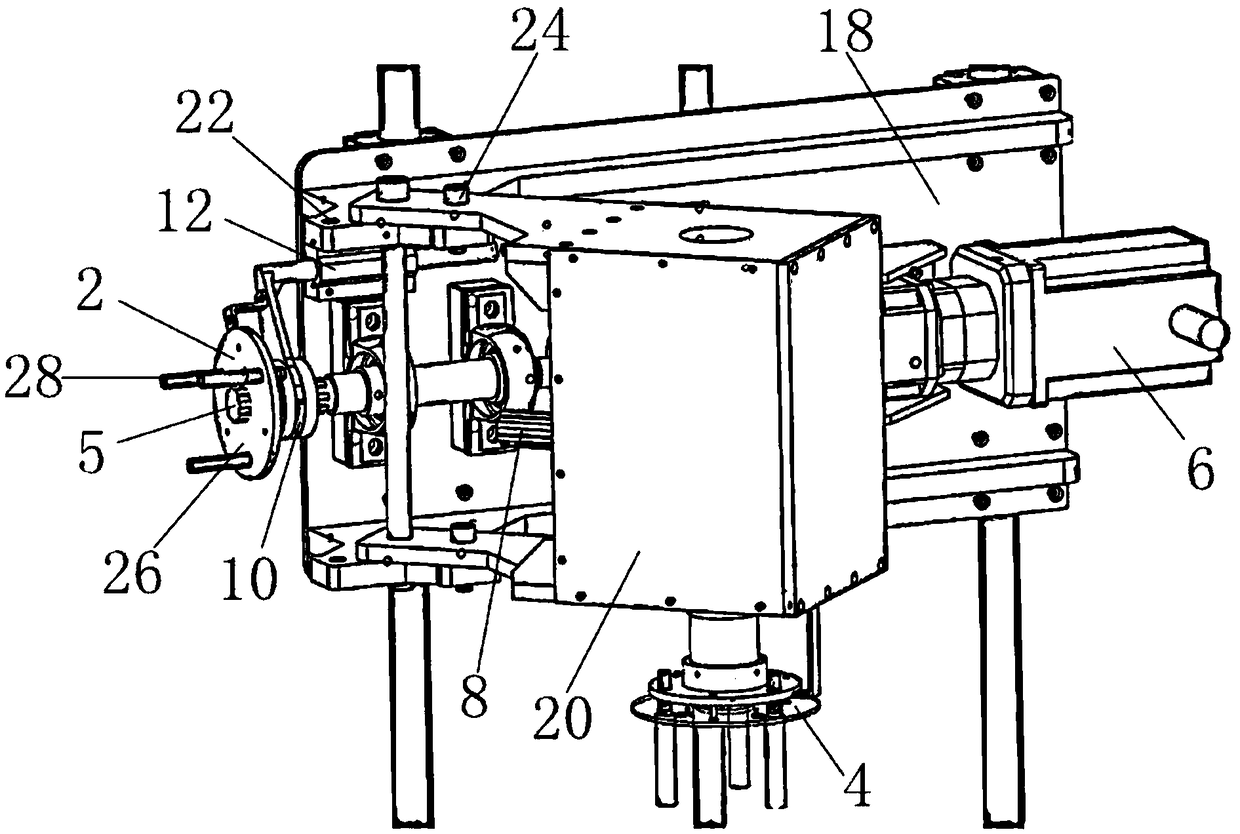

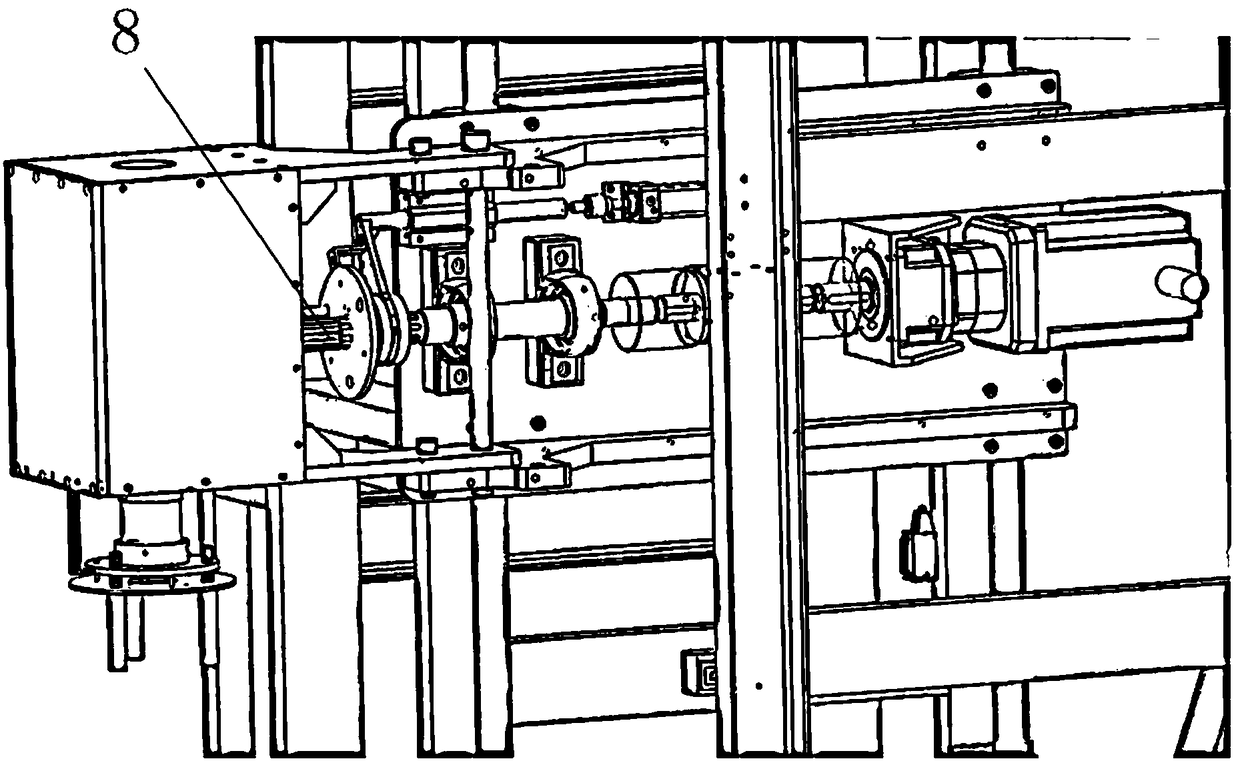

[0019] like Figure 1-2 As shown, this embodiment discloses a valve stem valve rotation device, including a first rotary actuator 2 and a second rotary actuator 4, the first rotary actuator 2 is fixed on the first spline shaft 5, and the first rotary actuator 4 is fixed on the first spline shaft 5. A spline shaft 5 rotates horizontally under the drive of the power source; the above-mentioned second rotary actuator 4 is fixed on the transmission mechanism, and the above-mentioned transmission mechanism can convert the horizontal rotation into vertical rotation; the above-mentioned transmission mechanism is fixed on the second spline shaft 8 Above; the above-mentioned first spline shaft 5 is spline-coupled with a sliding sleeve 10; the above-mentioned sliding sleeve 10 is connected to the switching mechanism, and the above-mentioned switching mechanism drives the sliding sleeve 10 to move axially along the first spline shaft 5, so that the second spline The key shaft 8 is spline...

Embodiment 2

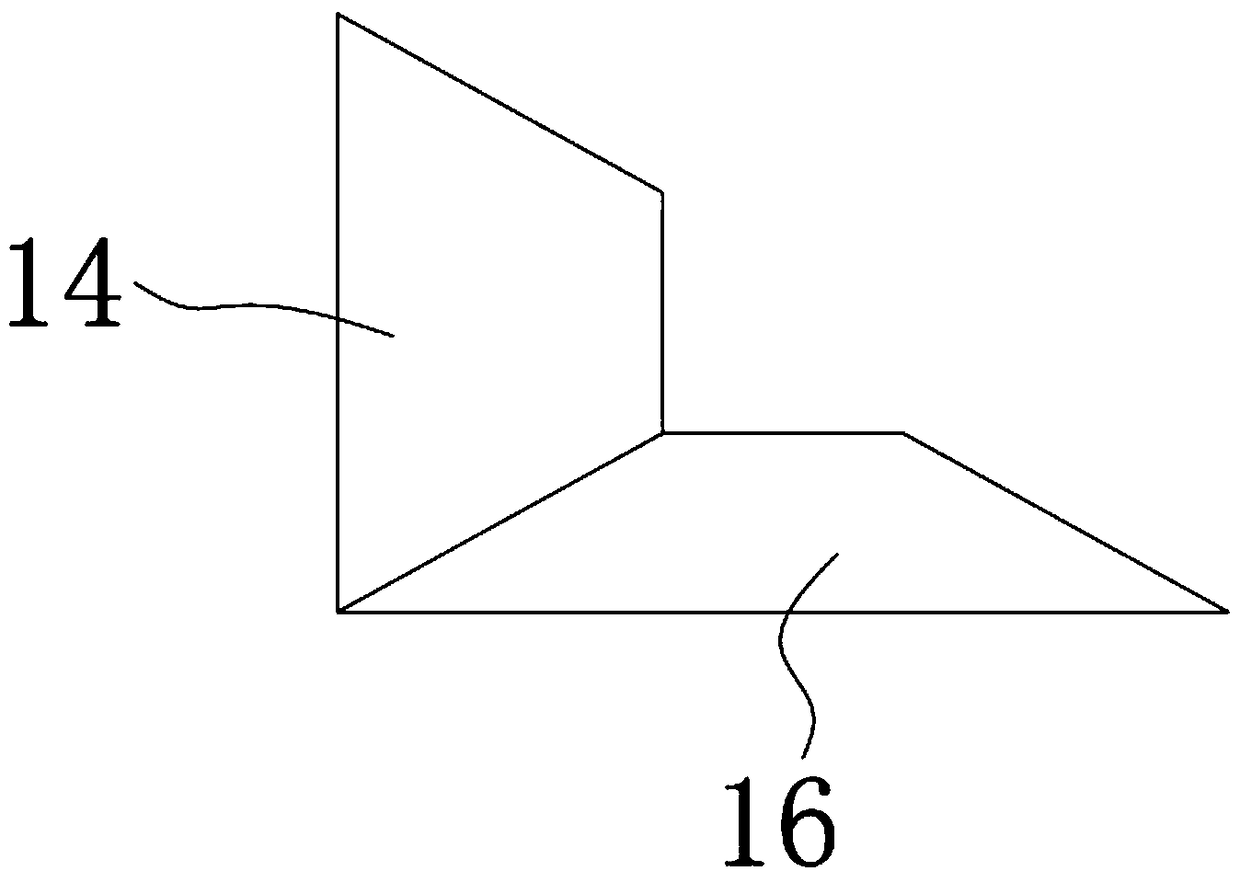

[0029] This embodiment discloses a valve stem valve rotation device. The difference between this embodiment and Embodiment 1 lies in the structure of the transmission mechanism. In the technical solution of this embodiment, the above-mentioned transmission mechanism is a first bevel gear and a second For the bevel gear, the above-mentioned first bevel gear is spline-coupled to the second spline shaft, and the above-mentioned second rotary actuator is fixed on the wheel shaft of the second bevel gear. The above-mentioned first bevel gear rotates horizontally, which drives the second bevel gear to rotate vertically. The transmission mechanism with the above structure can also realize the transformation of horizontal rotation and vertical rotation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com