Device and method for measuring response time and speed of proportional electromagnet action

A technology of proportional electromagnet and action response, applied in the direction of magnetic performance measurement, etc., can solve the problems of increased measurement complexity, broken armature push rod, and difficult measurement, so as to achieve accurate and reliable induction signals, not easy to be damaged by impact, and improve The effect of temporal resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

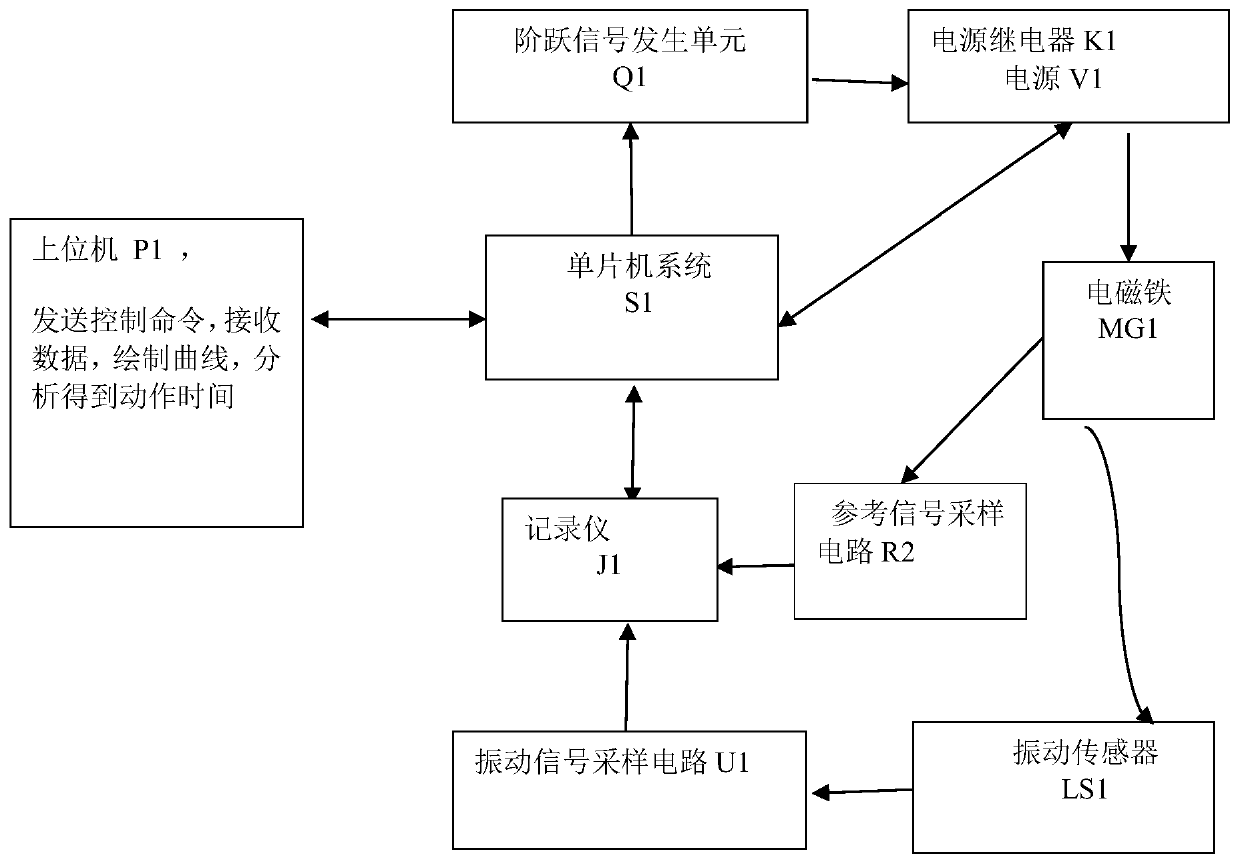

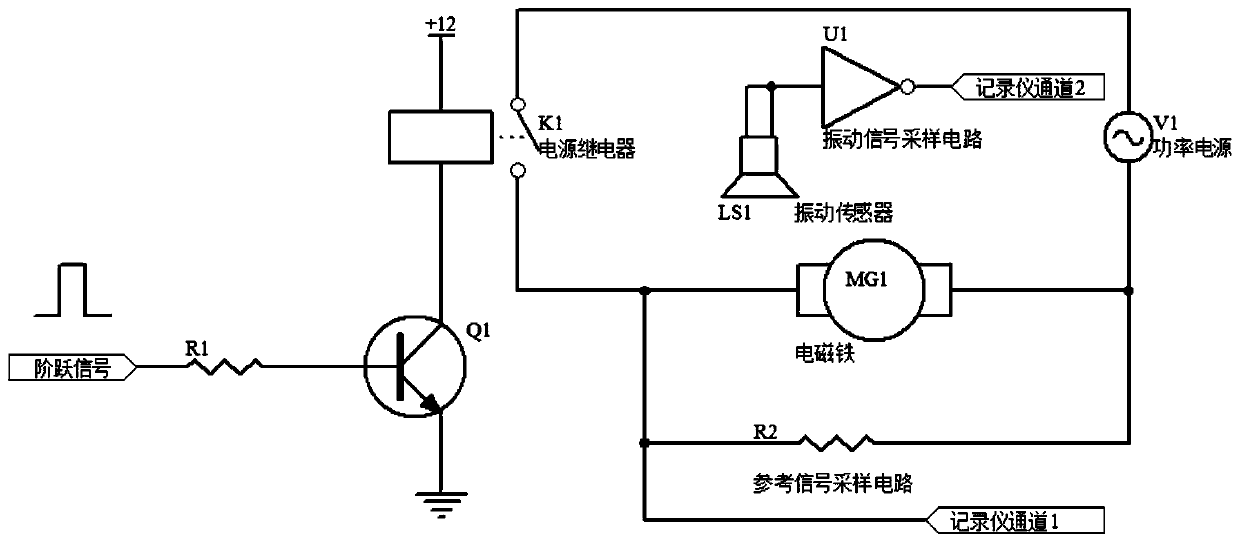

[0018] The device for measuring the action response time and speed of the proportional electromagnet includes: power relay K1, step signal generating unit Q1, reference signal sampling circuit R2, vibration sensor LS1, vibration signal sampling circuit U1, recorder J1, single-chip microcomputer system S1, The host computer P1, the step signal generating unit Q1 generates a step pulse signal and loads it on the power relay K1; the power relay K1 is used to control the on / off of the electromagnet power supply V1; the reference signal sampling circuit R2 It is connected in parallel with the coil of the electromagnet MG1, and is used to collect the electric pulse signal that excites the action of the armature of the electromagnet MG1; the vibration sensor LS1 is attached to the shell of the electromagnet MG1, and the vibration signal sampling circuit U1 is used to collect the signal of the vibration sensor LS1 The vibration signal is received, and the vibration signal comes from th...

Embodiment 2

[0020] The method for measuring the action response time and speed of the proportional electromagnet is realized based on the device of embodiment 1, and its steps include:

[0021] (1) The single-chip microcomputer generates a step pulse signal and loads it on the power relay; the pulse width is 10 milliseconds to 5000 milliseconds, the pulse width is 0 to 5V, and the rise / fall time of the step signal is less than 1 microsecond.

[0022] (2) The power supply relay is connected to the power supply to control the connection of the electromagnet power supply, thereby stimulating the movement of the electromagnet armature; the power supply is controlled by the single-chip microcomputer, and the output power is adjustable.

[0023] (3) The reference signal sampling circuit collects the voltage signal that excites the movement of the electromagnet armature and transmits it to the first channel of the recorder; through the sampling circuit, the voltage data obtained by the electromag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com