Degradation modeling and life prediction method of digital multimeter for water surface ship equipment

A digital multimeter, life prediction technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems that the degradation modeling method cannot solve engineering practical problems well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

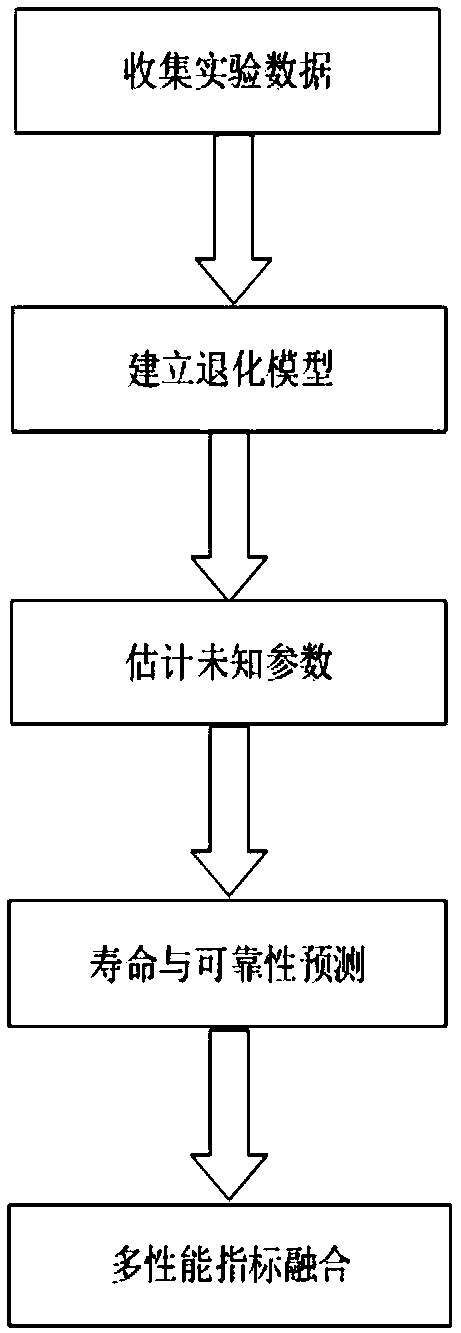

Method used

Image

Examples

Embodiment Construction

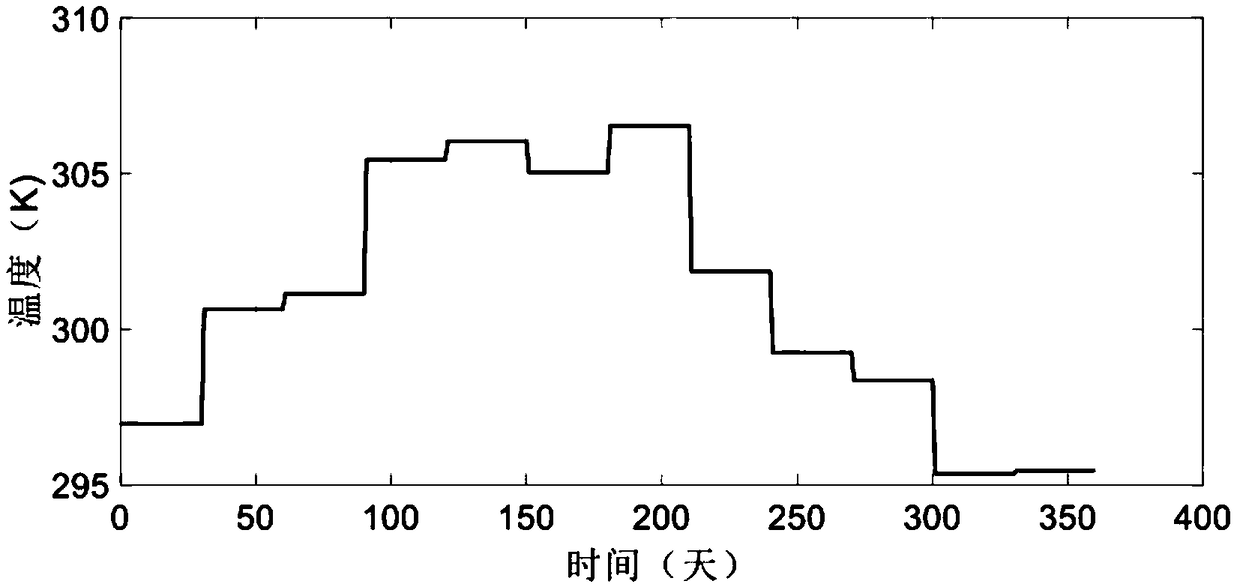

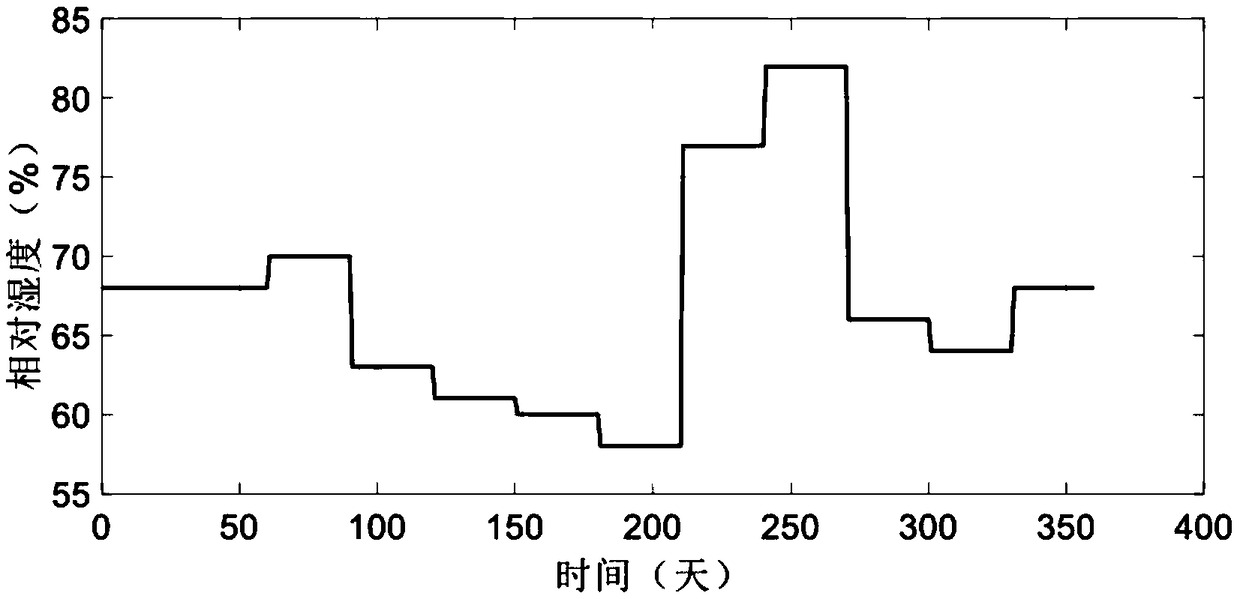

[0094] Based on the degradation test data of the multimeter under the combined action of temperature, relative humidity and salt spray three environmental stresses in the experiment, the experimental degradation data includes five measurement indicators of the multimeter DC voltage, DC current, AC voltage, AC current, and resistance. The degradation modeling method of this invention predicts the reliability of this table under the corresponding environmental stress profile in the future. The environmental stress (temperature, relative humidity, salt spray) profile settings of the multimeter in the experiment year are as follows Figure 2-4 Shown. The five performance indicators are respectively model-fitted using the first nine months of degradation data obtained in the experiment, and then the reliability of the multimeter in the future environmental profile for two years is predicted. Assuming that the product performance degradation process obeys the Wiener motion with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com