Medium-pressure air-insulated sealed switch cabinet

An air-insulated, switchgear technology, applied in switchgear, switchgear settings, electrical components, etc., can solve problems such as mechanism can not work normally, reduce the insulation strength in the cabinet, reduce product reliability, etc., to maintain the level of insulation strength , Improve the ability to resist phase-to-phase faults and maintain the effect of dielectric strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below with reference to the drawings and embodiments.

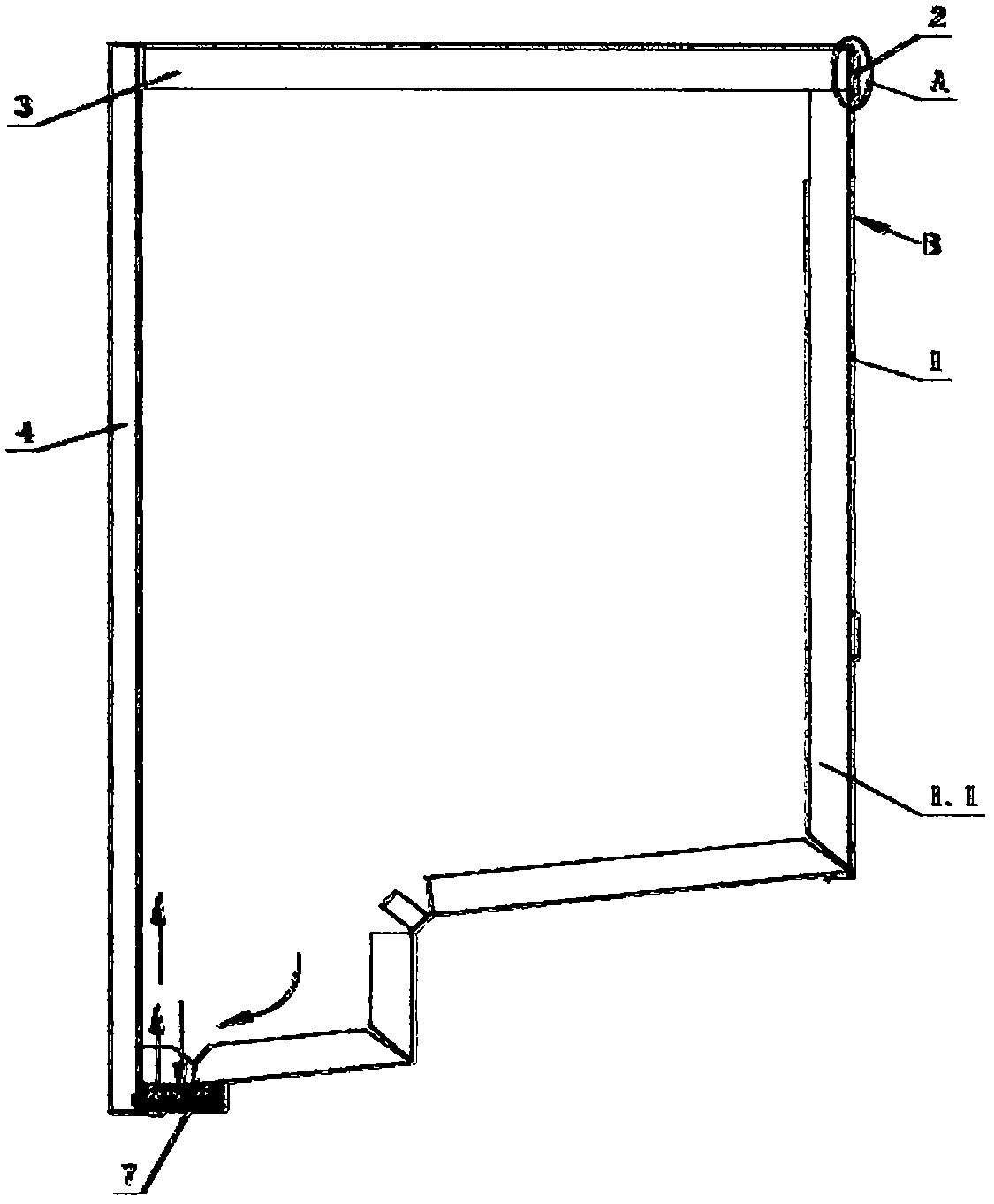

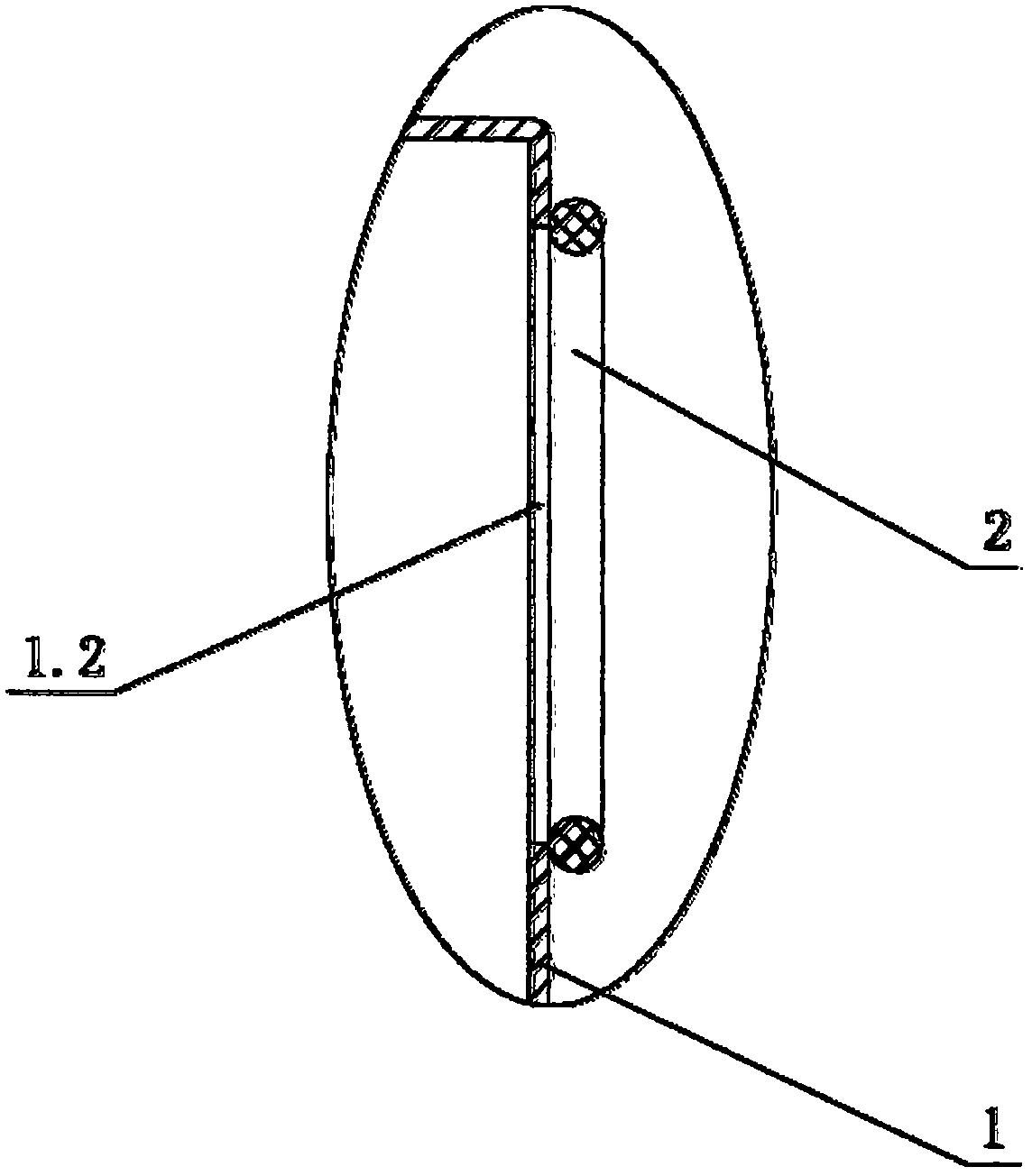

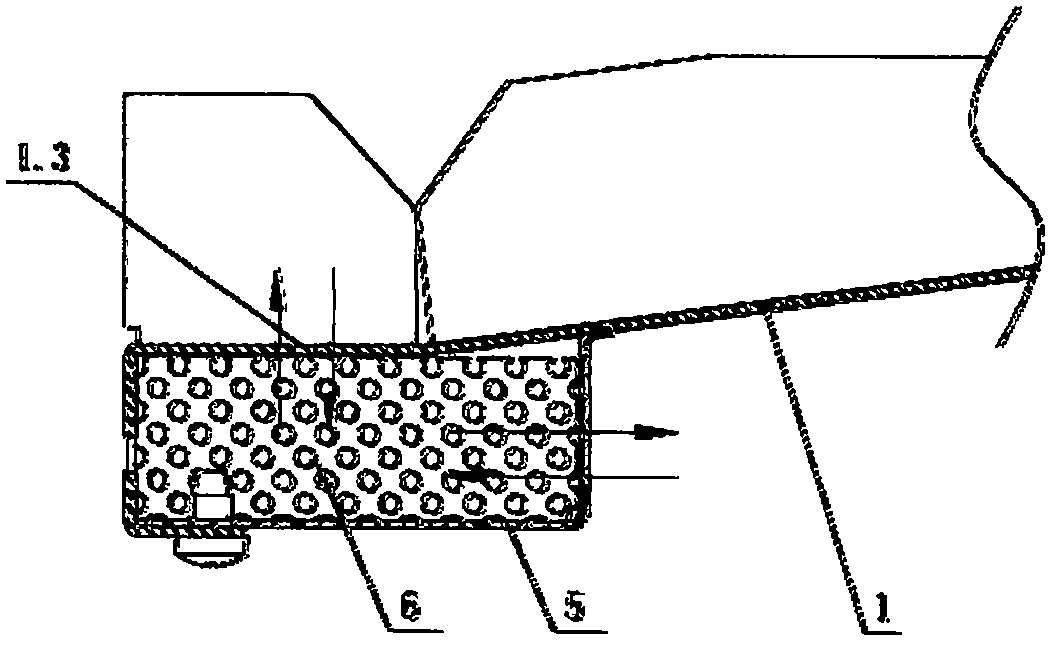

[0014] See Figure 1-Figure 3 , This medium-pressure air-insulated sealed switchgear includes a front panel 1, left and right side panels and a rear panel 4. The front panel 1, left and right side panels and the rear panel 4 are spliced with each other and fixed by fasteners, the front panel 1, left and right The side panel and the rear panel 4 are provided with a bending short side 1.1 and / or a corner panel, and a joint sealing area is formed by bending the short side 1.1 and / or the corner plate, and the switch cabinet is sealed by the seam A sealant is set on the top to form a permanently fixed and statically sealed box structure; the switch cabinet is also provided with a natural pressure relief balanced vent channel 7 that realizes the principle of self-balancing the internal and external air pressure of the sealed switch cabinet, so that the switch cabinet has a n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com