Manufacturing process of 6-layer microphone embedded circuit board with embedded chip

A technology of embedded chip and manufacturing process, applied in the direction of multi-layer circuit manufacturing, printed circuit manufacturing, printed circuit, etc., can solve the problems of limiting the space expansion and utilization rate of terminal products, and achieve favorable expansion, low cost investment, and improvement effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. However, the scope of protection of the present invention is not limited to the following examples, that is, any simple equivalent changes and modifications made based on the patent scope of the present invention and the content of the description are still within the scope of the patent of the present invention.

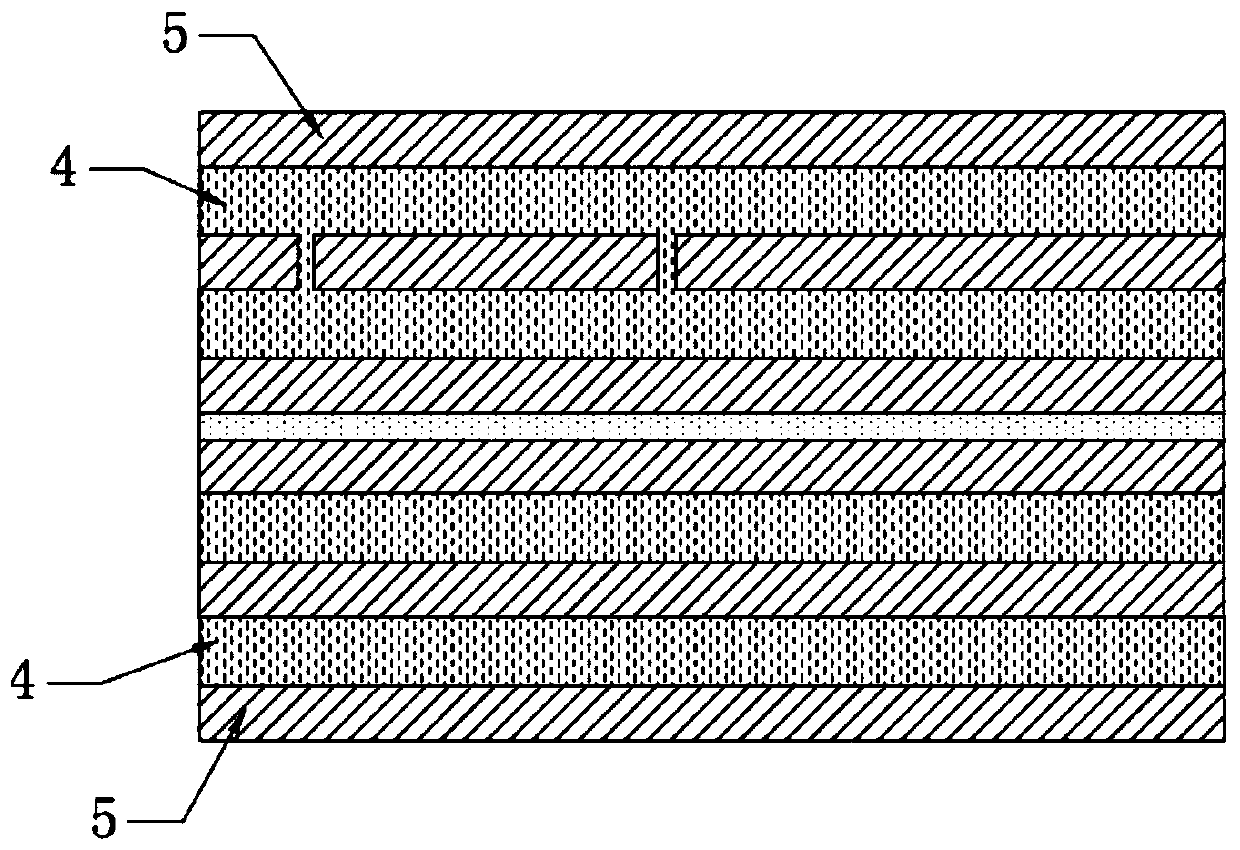

[0034] refer to Figure 1-7 , is a 6-layer microphone embedded circuit board manufacturing process for an embedded chip of the present invention, comprising the following steps:

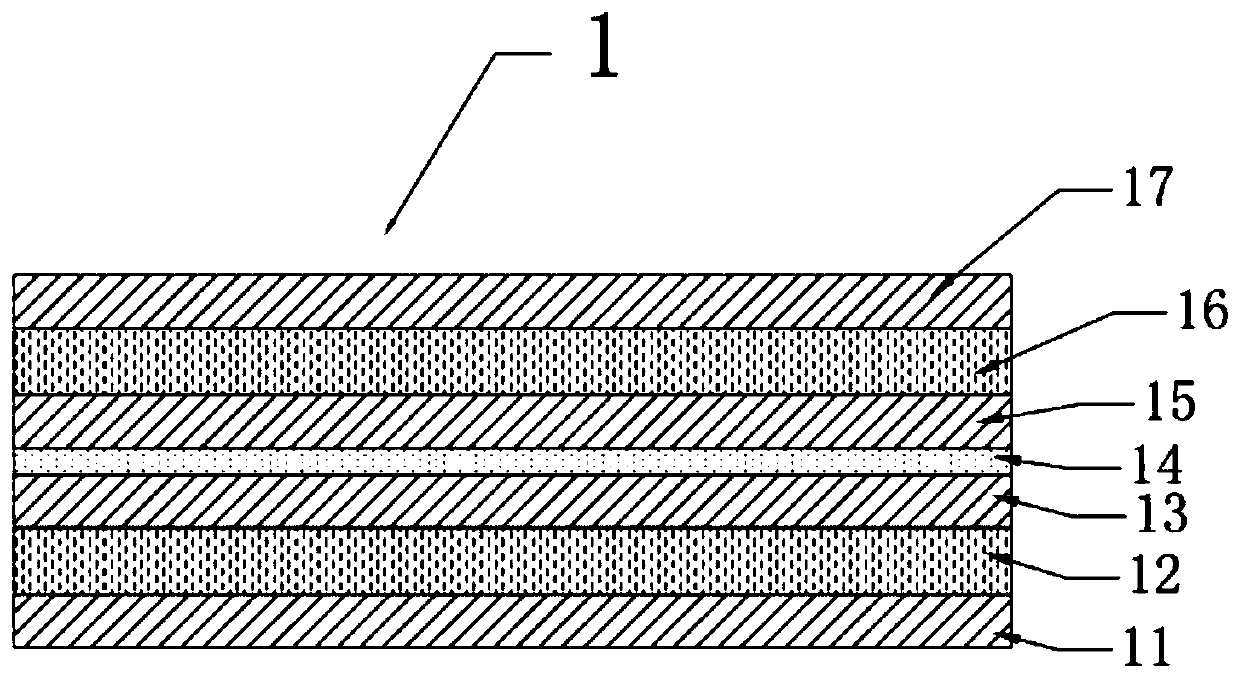

[0035] Step 1, preparing a four-layer embedded substrate 1 that has been laminated and etched twice;

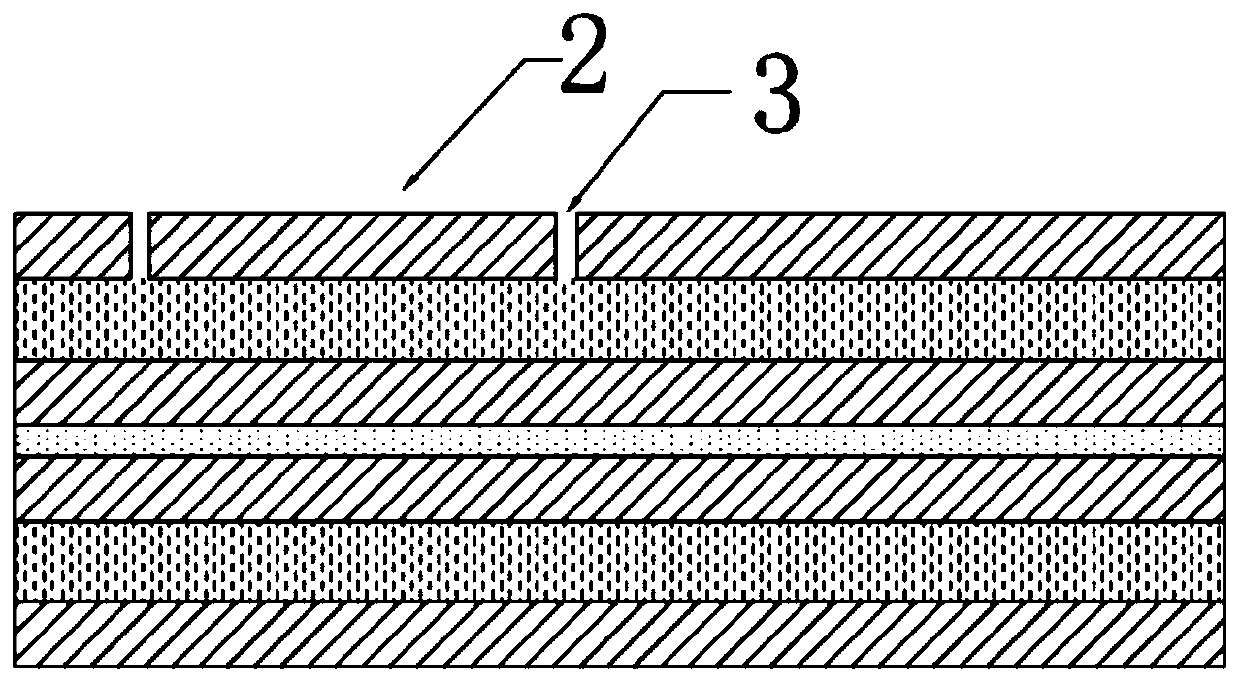

[0036] Step 2: Expose the double-sided laminated dry film of the four-layer embedded capacitor substrate, etch out the sub-outer layer pattern, and reserve the corresponding preset chip position on an outer layer copper foil of the four-layer embedded ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com