A two-stage supercharging device based on single-shaft loading

A two-stage pressurized, single-axis technology, applied in the field of in-situ neutron diffraction experiments, can solve the problems of gasket deformation and thinning, and achieve ideal results and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

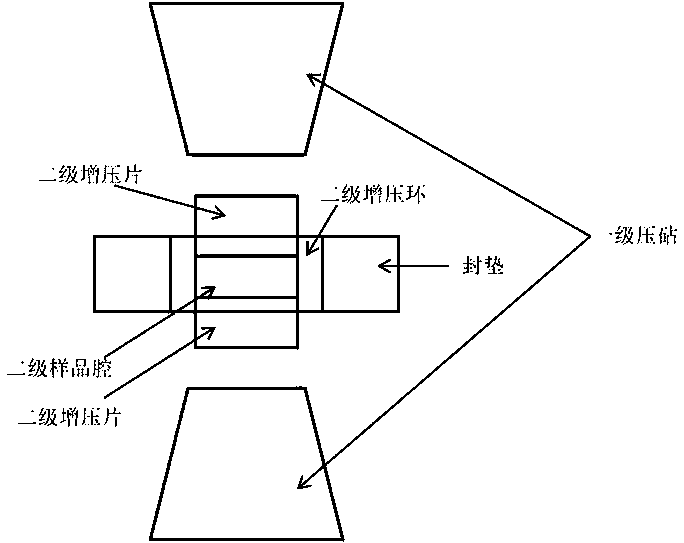

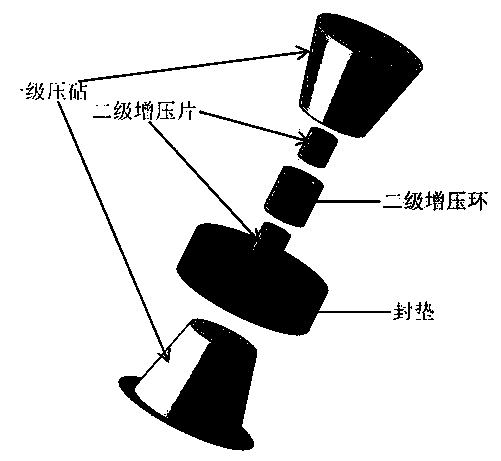

[0015] The structure of the two-stage supercharging device based on uniaxial loading for in-situ neutron diffraction experiments in this embodiment is as follows: figure 1 As shown, there is a first-level anvil on the upper and lower sides, and the anvil surfaces are opposite. There is a TiZr alloy gasket with a thickness of 3mm between the anvil surfaces of the two first-level anvils. Drilling is used as the primary pressure cavity with a diameter of 3mm. The primary pressure cavity is equipped with a secondary booster ring with an outer diameter of 3mm and an inner diameter of 2mm. The outer wall of the secondary booster ring matches the inner wall of the primary pressure cavity. , the upper and lower ports of the secondary booster ring are respectively provided with a secondary booster sheet with a diameter of 2mm and a height of 2mm, and the ZnTa sample is placed in the secondary sample chamber surrounded by the secondary booster ring and the secondary booster sheet, and in...

Embodiment 2

[0017] The structure of the two-stage supercharging device based on uniaxial loading for in-situ neutron diffraction experiments in this embodiment is as follows: figure 1 As shown, there is a first-level anvil on the upper and lower sides, and the anvil surfaces are opposite. There is a TiZr alloy gasket with a thickness of 3mm between the anvil surfaces of the two first-level anvils. Drilling is used as the primary pressure cavity with a diameter of 3mm. The primary pressure cavity is equipped with a secondary booster ring with an outer diameter of 3mm and an inner diameter of 2mm. The outer wall of the secondary booster ring matches the inner wall of the primary pressure cavity. , the upper and lower ports of the secondary booster ring are respectively provided with a secondary booster sheet with a diameter of 2mm and a height of 1.5mm, and the ZnTa sample is placed in the secondary sample chamber surrounded by the secondary booster ring and the secondary booster sheet, and ...

Embodiment 3

[0019] The structure of the two-stage supercharging device based on uniaxial loading for in-situ neutron diffraction experiments in this embodiment is as follows: figure 1 As shown, there is a first-level anvil on the upper and lower sides, and the anvil surfaces are opposite. There is a TiZr alloy gasket with a thickness of 4mm between the anvil surfaces of the two first-level anvils. Drilling is used as the primary pressure cavity with a diameter of 4mm. The primary pressure cavity is equipped with a secondary booster ring with an outer diameter of 4mm and an inner diameter of 3mm. The outer wall of the secondary booster ring matches the inner wall of the primary pressure cavity. , the upper and lower ports of the secondary booster ring are respectively provided with a secondary booster sheet with a diameter of 3mm and a height of 1.5mm, and the ZnTa sample is placed in the secondary sample chamber surrounded by the secondary booster ring and the secondary booster sheet, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com