Quartz nozzle and preparation method thereof

A technology of quartz nozzles and quartz tubes, which is applied in stone processing equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of accelerated cooling, condensation blocking pipes, and low precision of nozzle holes, and achieves controllable diameter and roundness. Improve consistency and maintain stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

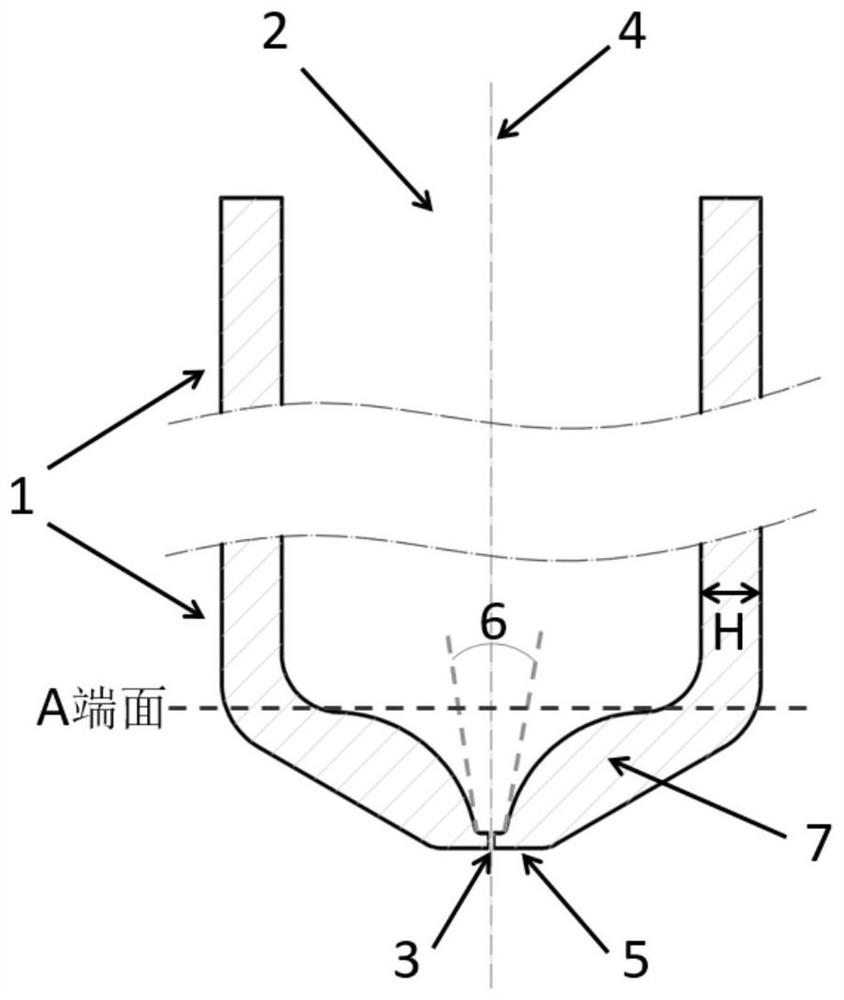

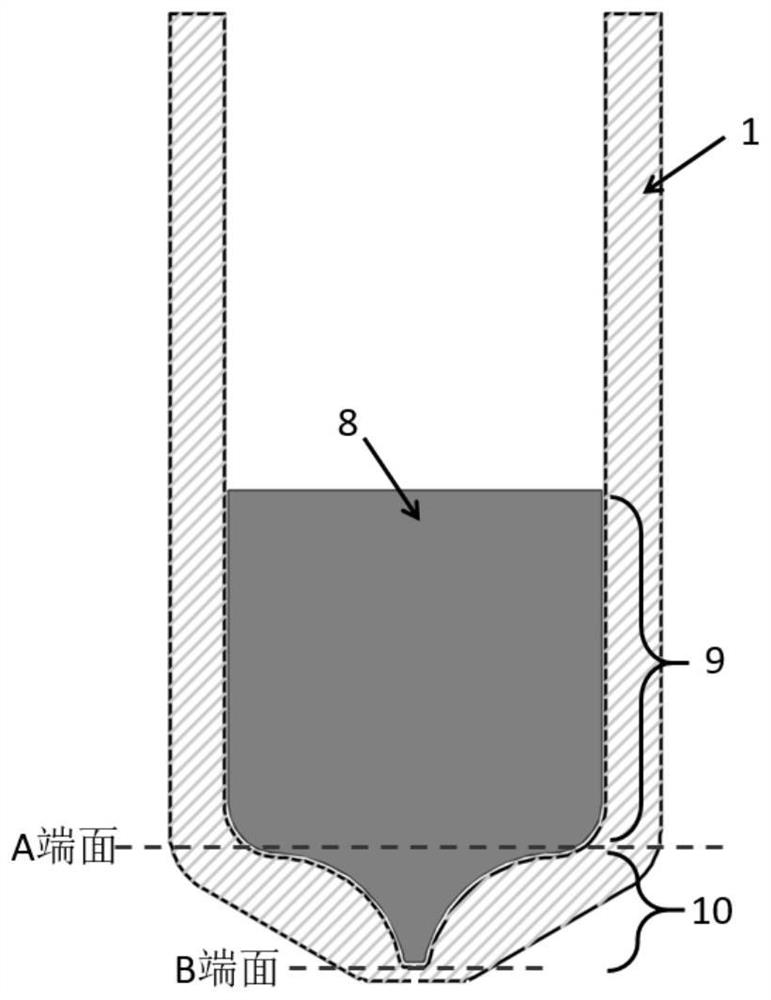

[0031] like figure 1 As shown, the quartz nozzle includes a hollow quartz tube 1 with openings at both ends. The thickness H of the tube wall of the quartz tube is 1.5mm. Along the length direction of the quartz tube, the tube wall at the A end of the quartz tube 1 gradually approaches the central axis 4. The opening 2 at the end A forms a funnel-shaped structure, and the opening 3 forms a nozzle hole of the funnel-shaped structure, and the diameter of the opening 3 is 0.12 mm.

[0032] In this embodiment, the pipe wall at the end A is planarized to the outer wall of the end 5 close to the central axis 4, that is, the outer wall of the end 5 is formed into a plane by means of external mechanical extrusion or grinding.

[0033] In this embodiment, when the pipe wall at end A approaches the central axis 4, the inner wall 7 of the pipe wall "expands" to form an outer convex surface, and the tangential angle 6 of the outer convex surface is 30°, thereby increasing the diameter of ...

Embodiment 2

[0042] In this embodiment, the structure of the quartz nozzle package is basically the same as that of Embodiment 1, the difference is that the thickness H of the quartz tube wall is 1.0 mm; the diameter of the opening 3 is 0.3 mm; Convex surface, the tangential angle 6 of the outer convex surface is 90°.

[0043] In this embodiment, the preparation method of the quartz nozzle is basically the same as that of Example 1, except that the quartz tube 1 with a tube wall thickness H of 1.0 mm is used; The tube is burned and softened for drawing, and the inner wall of the quartz tube 1 is tightly attached to and covers the frustum structure of the mold. Since the inner concave arc surface can make the inner wall of the quartz tube covered with the frustum structure be convex, the outer convex surface The tangential angle 6 is 90°; and a nozzle hole with a diameter of 0.3 mm is obtained when laser drilling is performed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com