Plug

A plug and sleeve technology, applied in the field of leak detection devices, can solve problems such as poor sealing effect, misjudgment of test, small contact surface, etc., and achieve good sealing performance, convenient operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions in the embodiments of the present application will be described below with reference to the drawings in the embodiments of the present application.

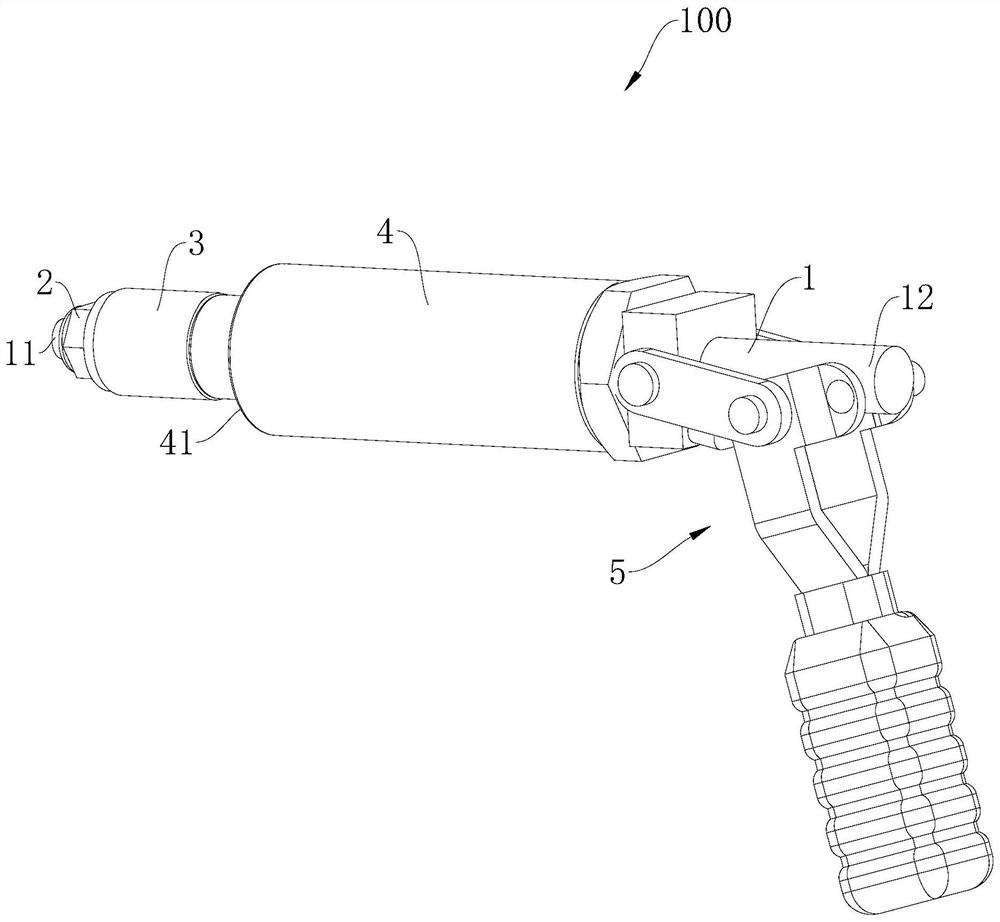

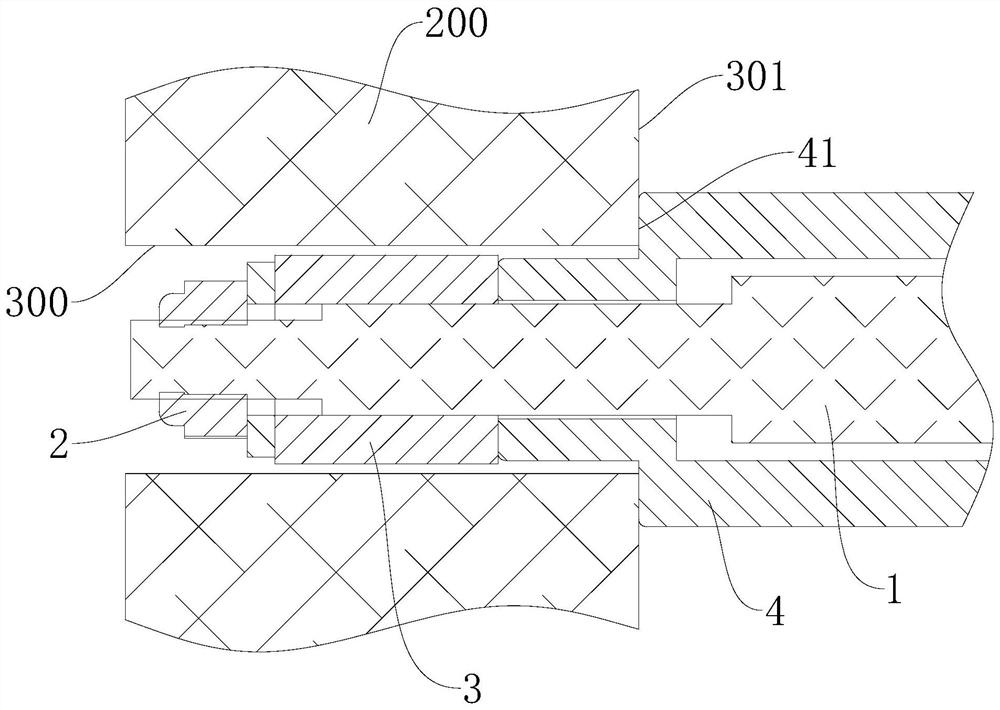

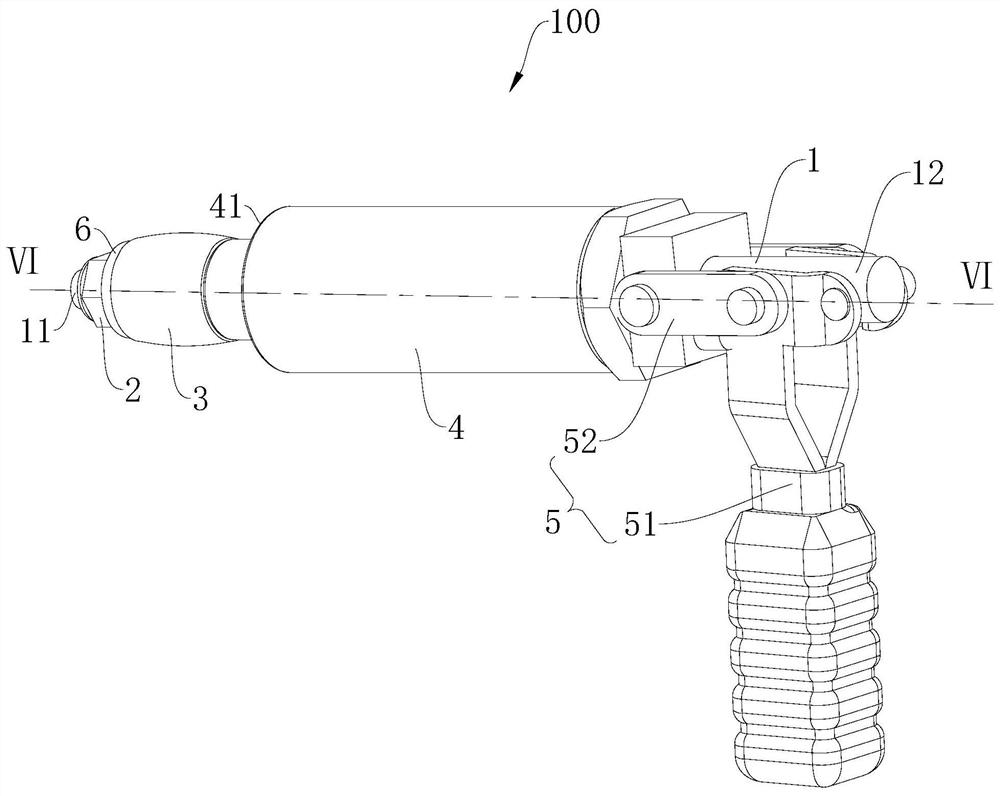

[0033] Please also refer to Figure 1 to Figure 6 , the embodiment of the present application provides a plug 100, and the plug 100 can be used to seal the channel 300 to be sealed of the housing 200 to be tested for leak tightness.

[0034] The plug 100 includes a main rod 1 , a pressing piece 2 , a sealing ring 3 , a sleeve 4 and a push-pull assembly 5 . The main rod 1 includes a first end 11 and a second end 12 oppositely disposed. The pressing member 2 is fixed on the first end 11 . The sealing ring 3 is slidingly sleeved on the outer peripheral side of the main rod 1 and located between the pressing member 2 and the second end 12 . The sleeve 4 is slidably sleeved on the outer peripheral side of the main rod 1 and located between the sealing ring 3 and the second end 12 . The outer peripher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com