A coating device for producing hot melt adhesive film

A technology of coating device and hot melt adhesive film, which is applied to the device and coating of the surface coating liquid, can solve the problems of affecting the yield and uneven coating, so as to improve the quality, improve the uniformity, reduce the The effect of loss of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

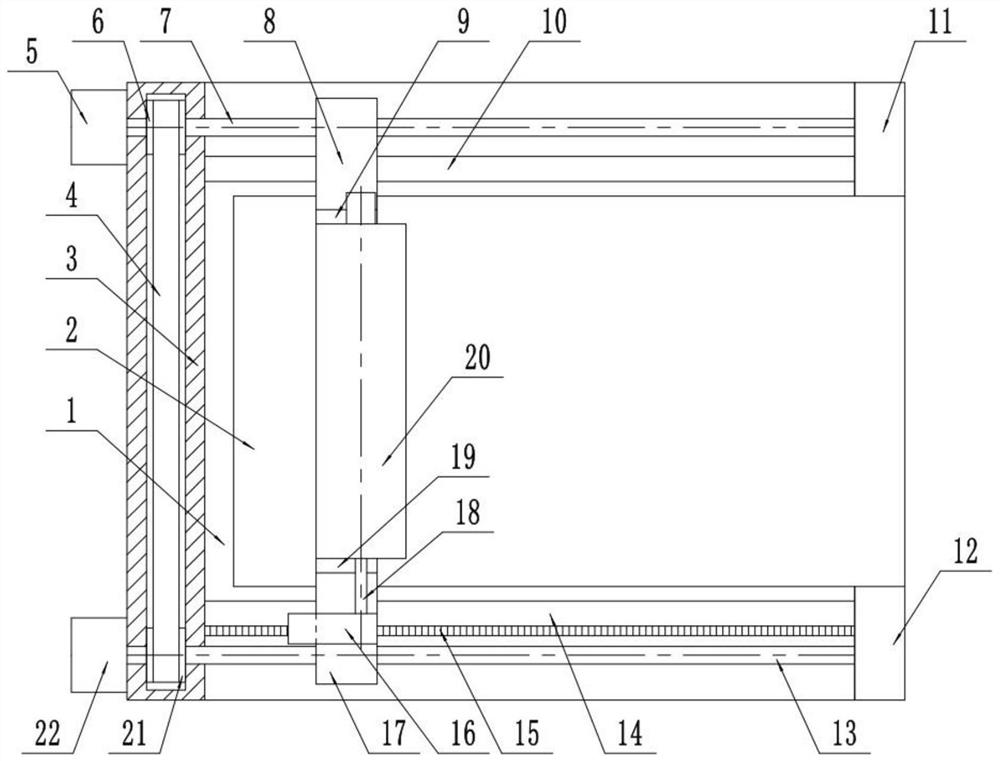

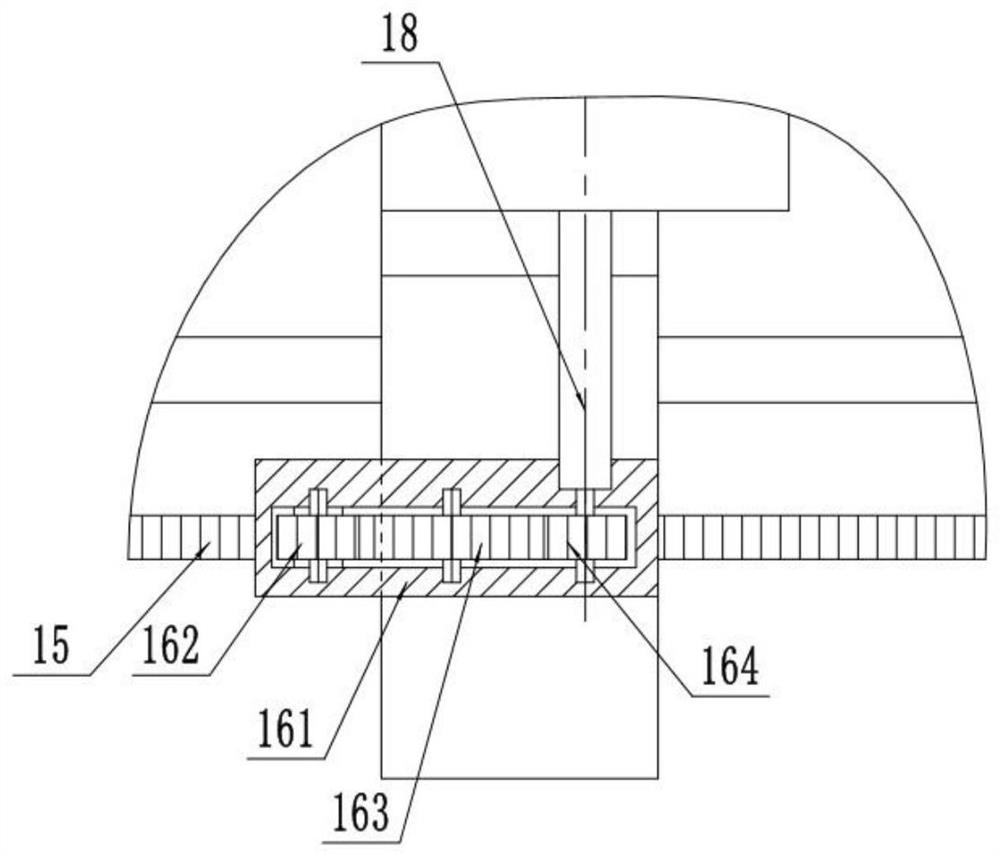

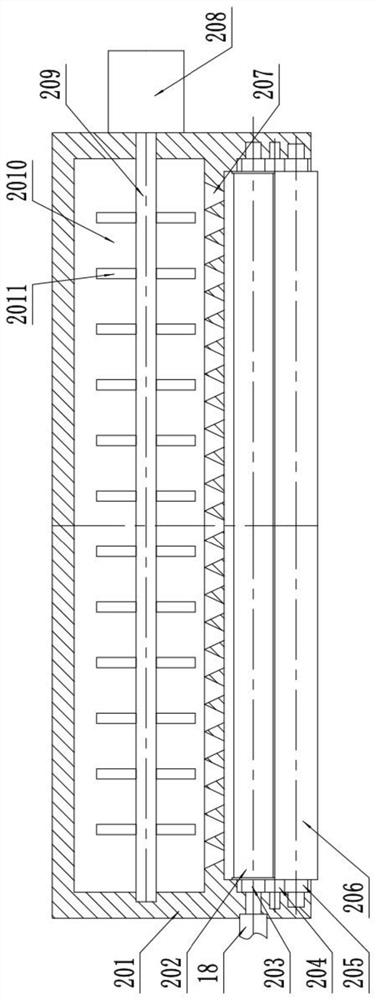

[0019] Such as figure 1 As shown, the present embodiment adopts the following technical solutions: a coating device for producing hot-melt adhesive films, including a frame 1, a table top 2, a casing 3, a transmission belt 4, a motor-5, a pulley-6, Screw one 7, movable seat one 8, connector one 9, guide rail one 10, limit block one 11, limit block two 12, screw rod two 13, guide rail two 14, rack 15, transmission device 16, movable seat two 17 , transmission shaft 18, connector two 19, coating mechanism 20, pulley two 21 and motor two 22; said frame 1 is provided with a table top 2 in the center, and said frame 1 is provided with guide rails two on both sides, front and rear respectively 14 and guide rail one 10; the box body 3 is fixedly connected to the left end face of the frame 1; movable seat one 8 is connected to the left and right above the guide rail one 10, and the limit block one 11 is fixedly connected to the right end of the guide rail two 14; The outer threaded h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com