Paper feeding device for beta ray-method PM10 online monitor

A monitor and beta-ray technology, applied in the direction of instruments, analytical materials, etc., can solve the problem of different moving amounts of filter paper, and achieve the effect of no paper breakage, smooth movement, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

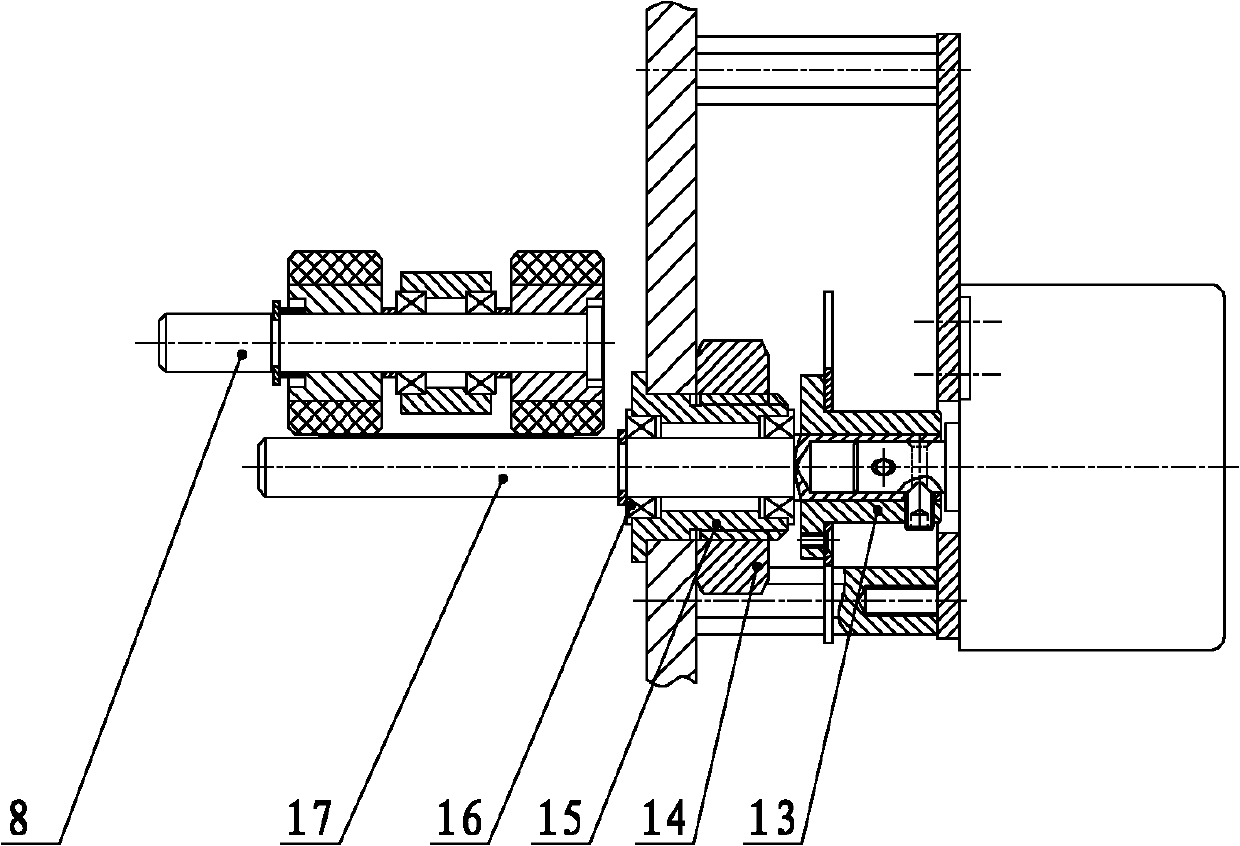

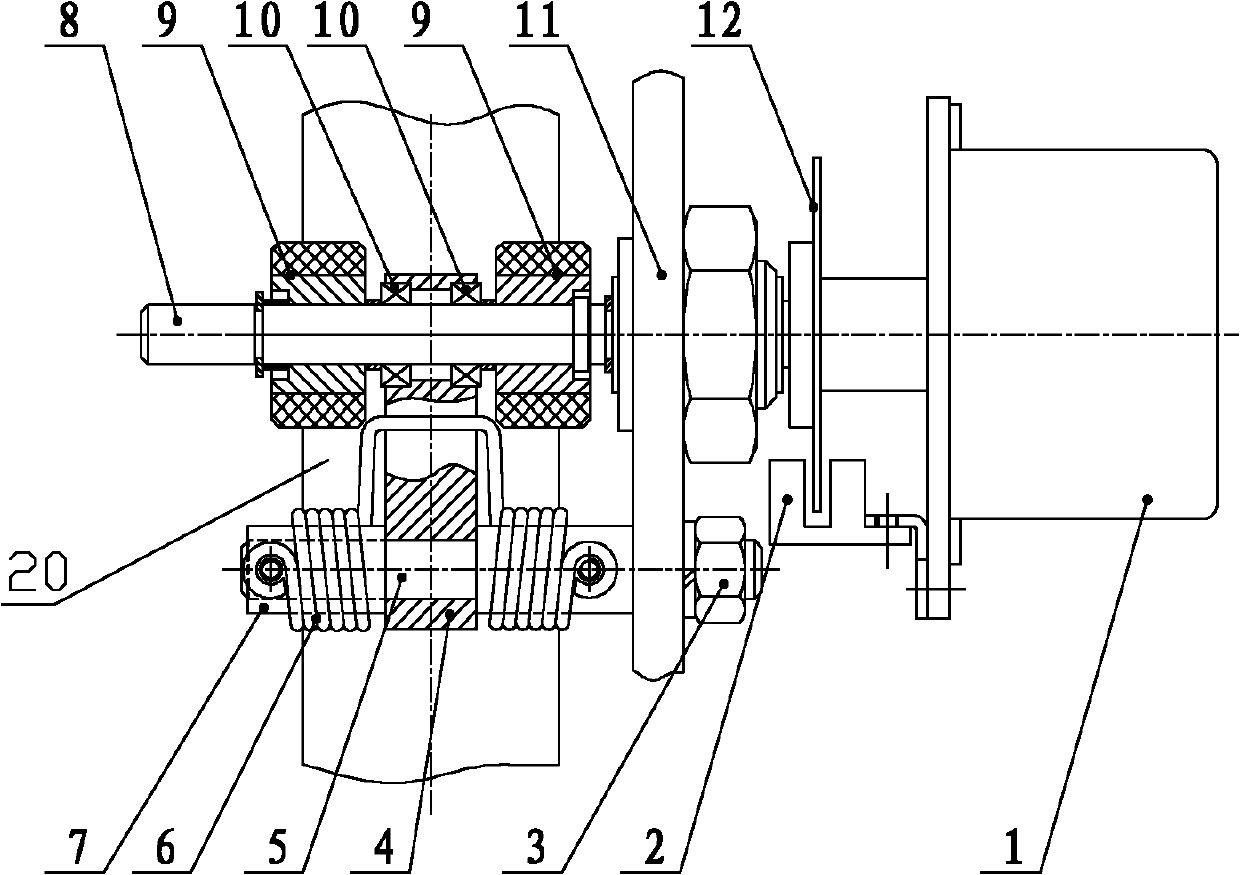

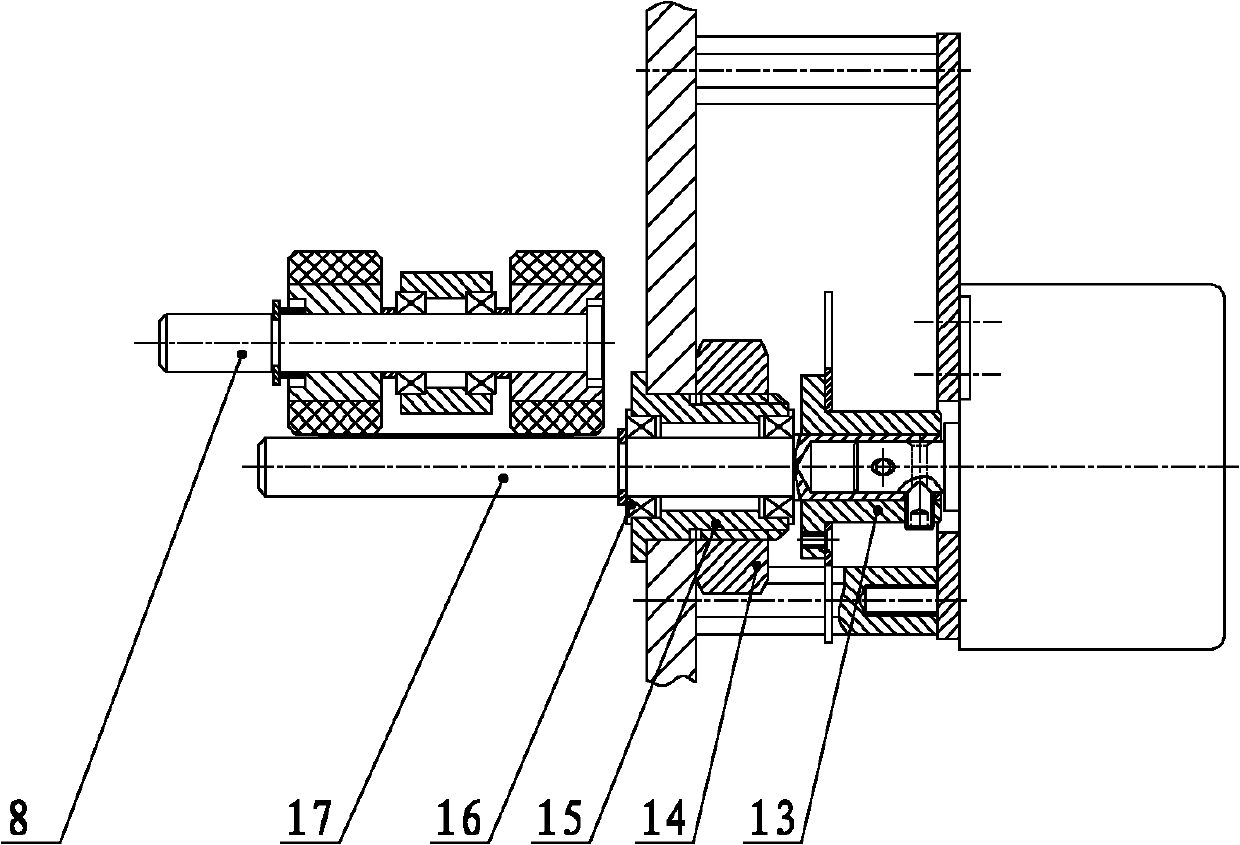

[0010] A kind of beta ray method PM10 online monitor paper-feeding device of the present invention, such as figure 1 , figure 2 As shown, it includes a main board 11, a drive shaft 17, a fixed shaft 5 parallel to the drive shaft 17 and fixedly connected to the main board 11, and a claw pole motor 1 fixed on the main board 11. The fixed shaft 5 is fixed on the main board 11 through the lock nut 3 , and the claw pole motor 1 is connected on the main board 11 through a plurality of spacers 19 . like figure 1 As shown, the drive shaft 17 is movably coupled to the main board 11 through the bearing 16 , the support sleeve 15 and the fastening nut 14 . The claw pole motor 1 , which is located below the filter paper 20 and is movably connected to the main board 11 , is in drive connection with the drive shaft 17 to drive the drive shaft 17 to rotate. A driven shaft 8 parallel to the driving shaft 17 is arranged above the filter paper 20 , and two rubber rollers 9 capable of rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com