A kind of automatic leveling method of sls metal 3d printer

A 3D printer and automatic leveling technology, which is applied to the improvement of process efficiency, additive manufacturing, additive processing, etc., can solve the problems of inability to guarantee the leveling accuracy, inconvenient leveling process, and time-wasting, and achieve easy disassembly , High commercial value, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing.

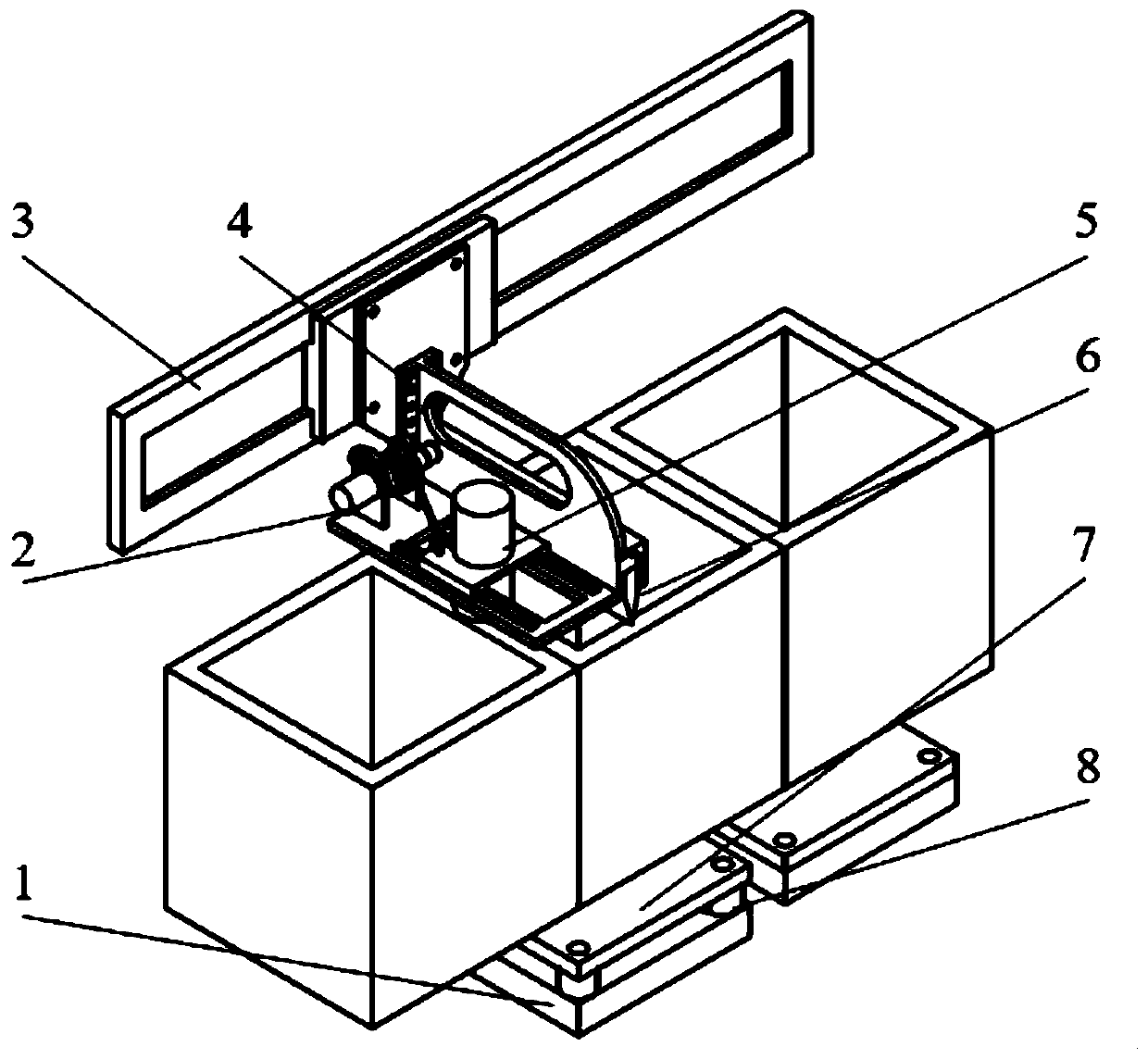

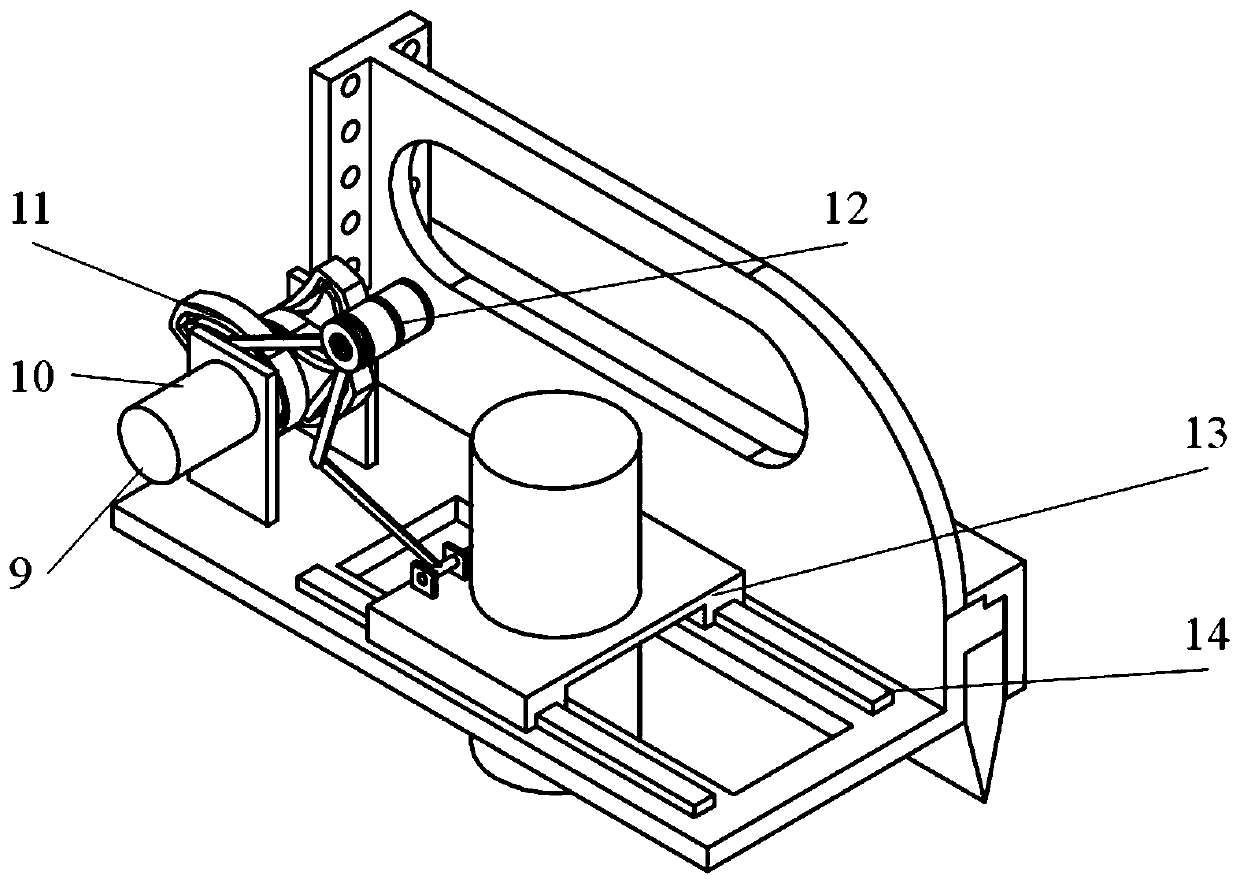

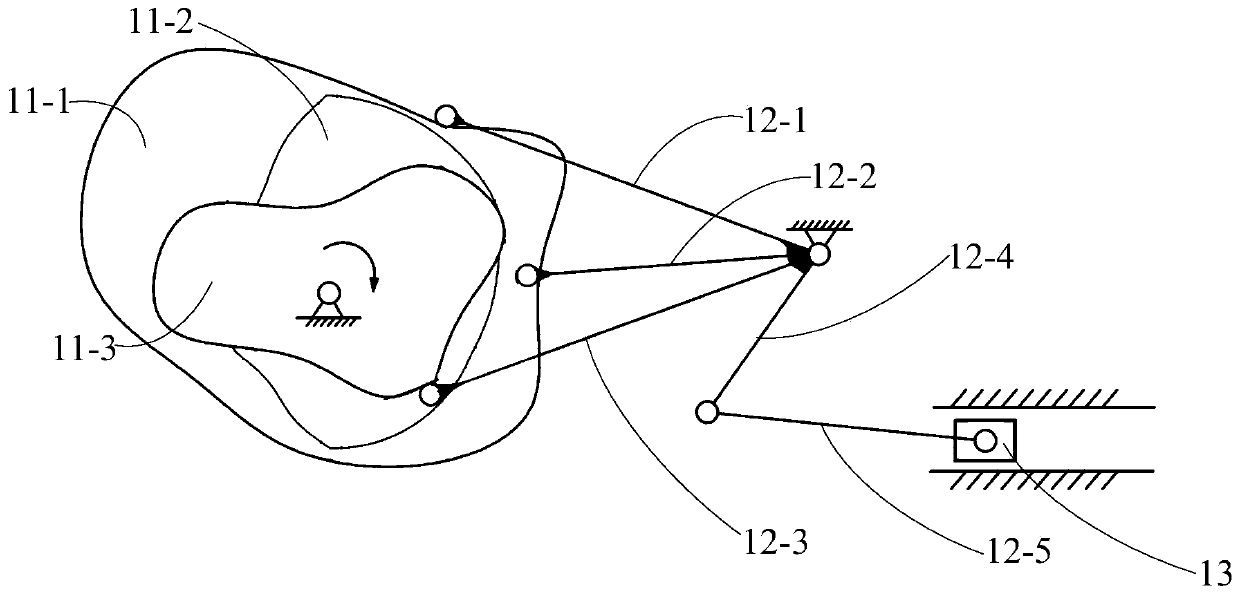

[0041] like figure 1 As shown, the present invention is mounted on a SLS metal 3D printer using a leveling device. The SLS metal 3D printer includes a frame, a horizontal slide rail 3 , a powder spreading vehicle 4 , a molding cylinder 1 and a molding platform 7 . Forming cylinder 1 and horizontal slide rail 3 are all fixed on the frame. The powder spreading car 4 and the horizontal slide rail 3 form a sliding pair. The forming platform 7 is installed on the forming cylinder 1 . The scraper 6 fixed on the powder spreading car 4 is located above the molding platform.

[0042] The working process of the SLS metal 3D printer is as follows: the powder spreading car 4 slides along the horizontal slide rail 3, the scraper 6 fixed on the powder spreading car 4 spreads a layer of powder material on the forming platform 7, and the laser beam is sintered on the powder layer to ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com