Paper loop glue rolling device and full-automatic production equipment for toilet paper reels

A technology of rolling rubber and paper rings, which is applied in the direction of cardboard items, transportation and packaging, and conveyor items, etc. It can solve the problem that the coaxiality of two paper trays cannot be guaranteed, and the size of toilet paper coils cannot be compatible, which affects production efficiency. And other problems, to achieve the effect of improving work efficiency and stability, increasing the processing range, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

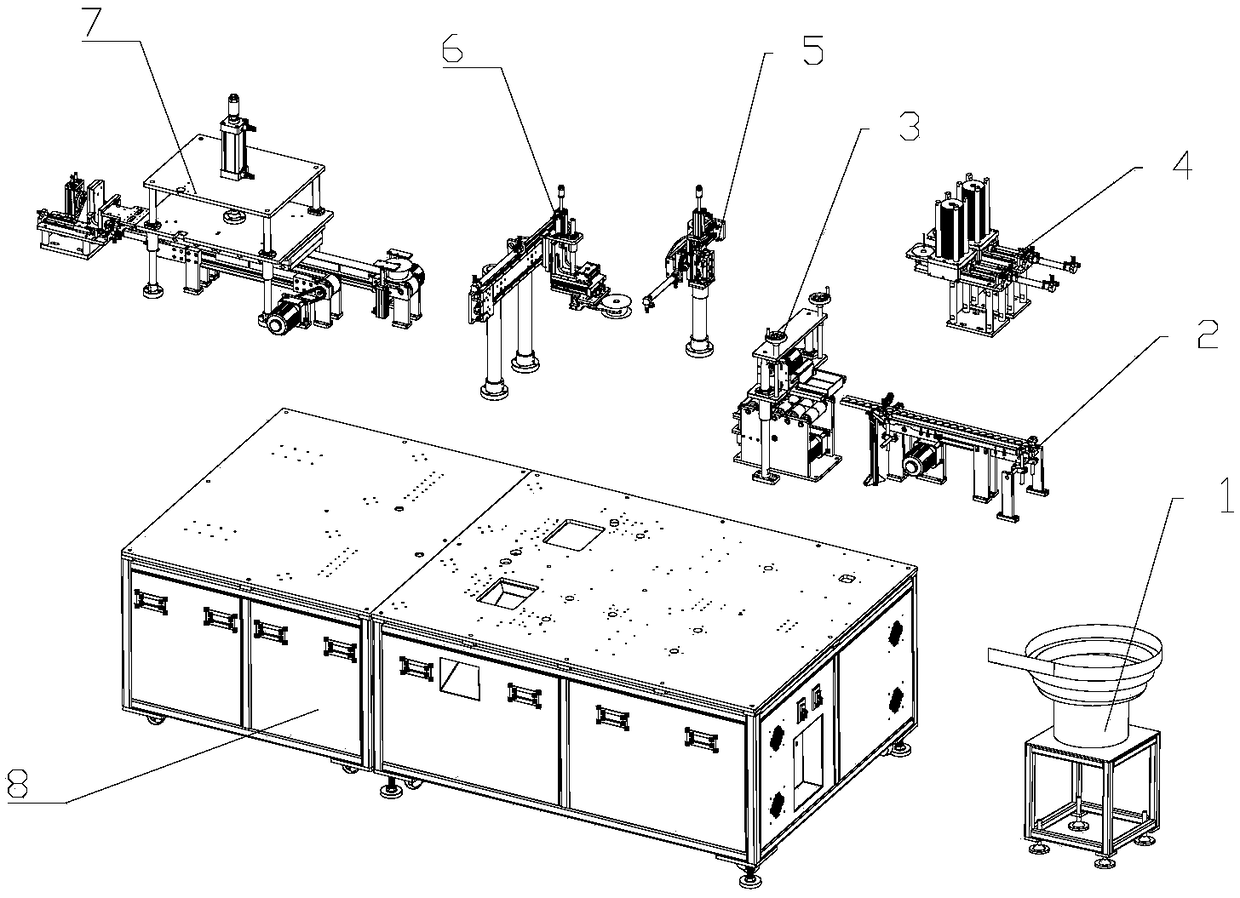

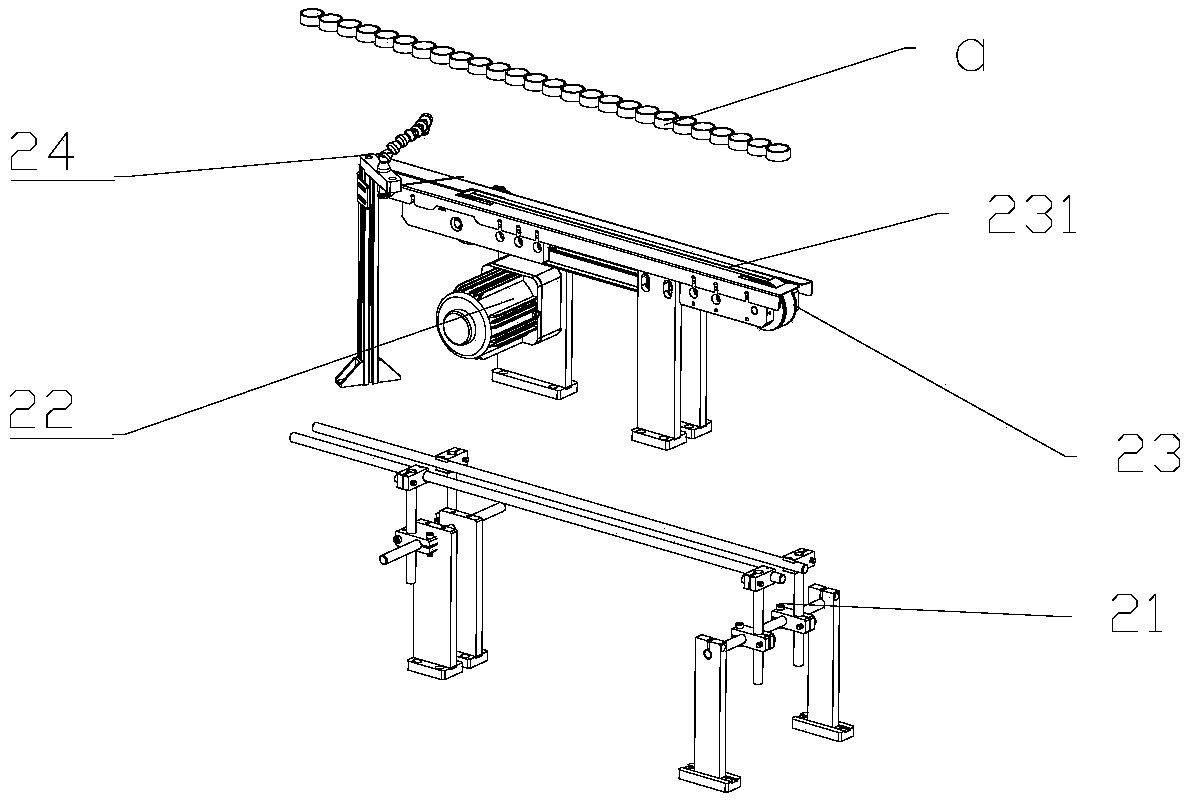

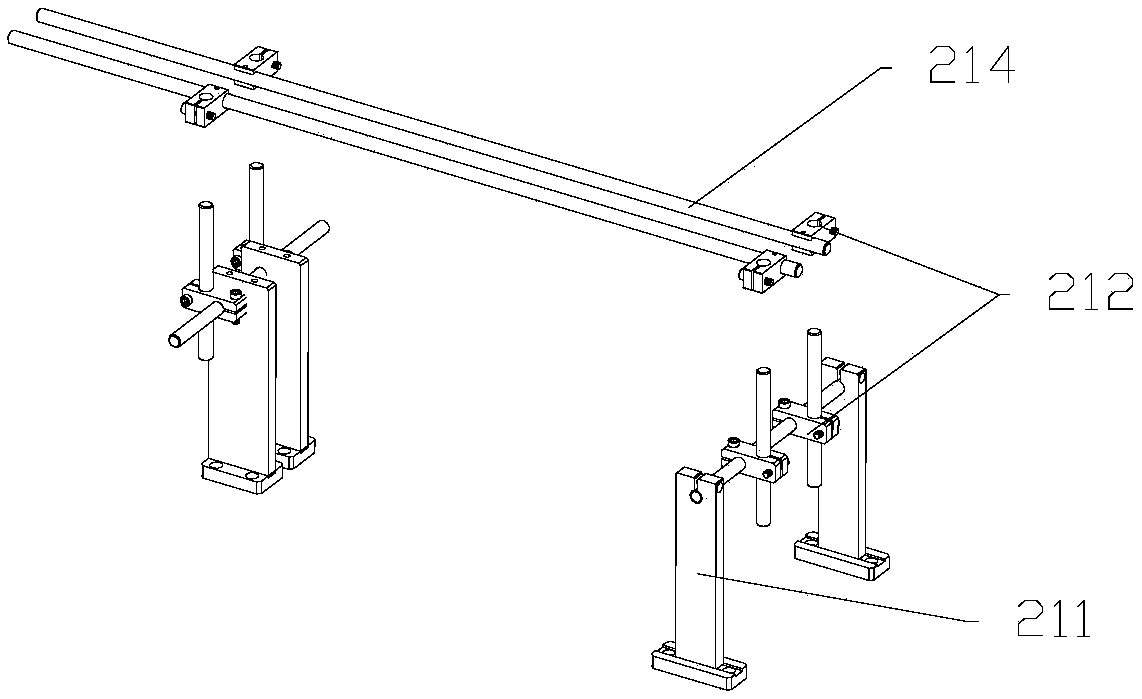

[0022] Such as Figure 1-Figure 10 As shown, the automatic production equipment for toilet paper coils includes a paper ring feeding device 1, a frame 8 and a paper ring feeding device 2 on the frame 8, a paper ring rolling device 3, a paper tray distributing device 4, Paper tray conveying device 5, paper ring conveying device 6 and baking device 7. The paper ring feeding device 1 is connected with the paper ring feeding device 2, the paper ring feeding device 2 is connected with the paper ring rolling device 3, the position of the paper tray conveying device 5 corresponds to the paper tray distributing device 4, and the paper ring conveying device 6 The position corresponds to the paper ring rolling device 3, the paper tray distributing device 4 and the baking device 7.

[0023] Paper ring feeding device 1 is used for paper ring feeding. The paper r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com