Flat door frame

A door frame and flat frame technology, applied in the field of new door frames, can solve the problems of increased transportation costs, large labor costs, and poor layout and stacking, and achieve novel and unique structural composition, significant economic benefits, and reduced transportation costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Now in conjunction with accompanying drawing, the present invention is described in detail:

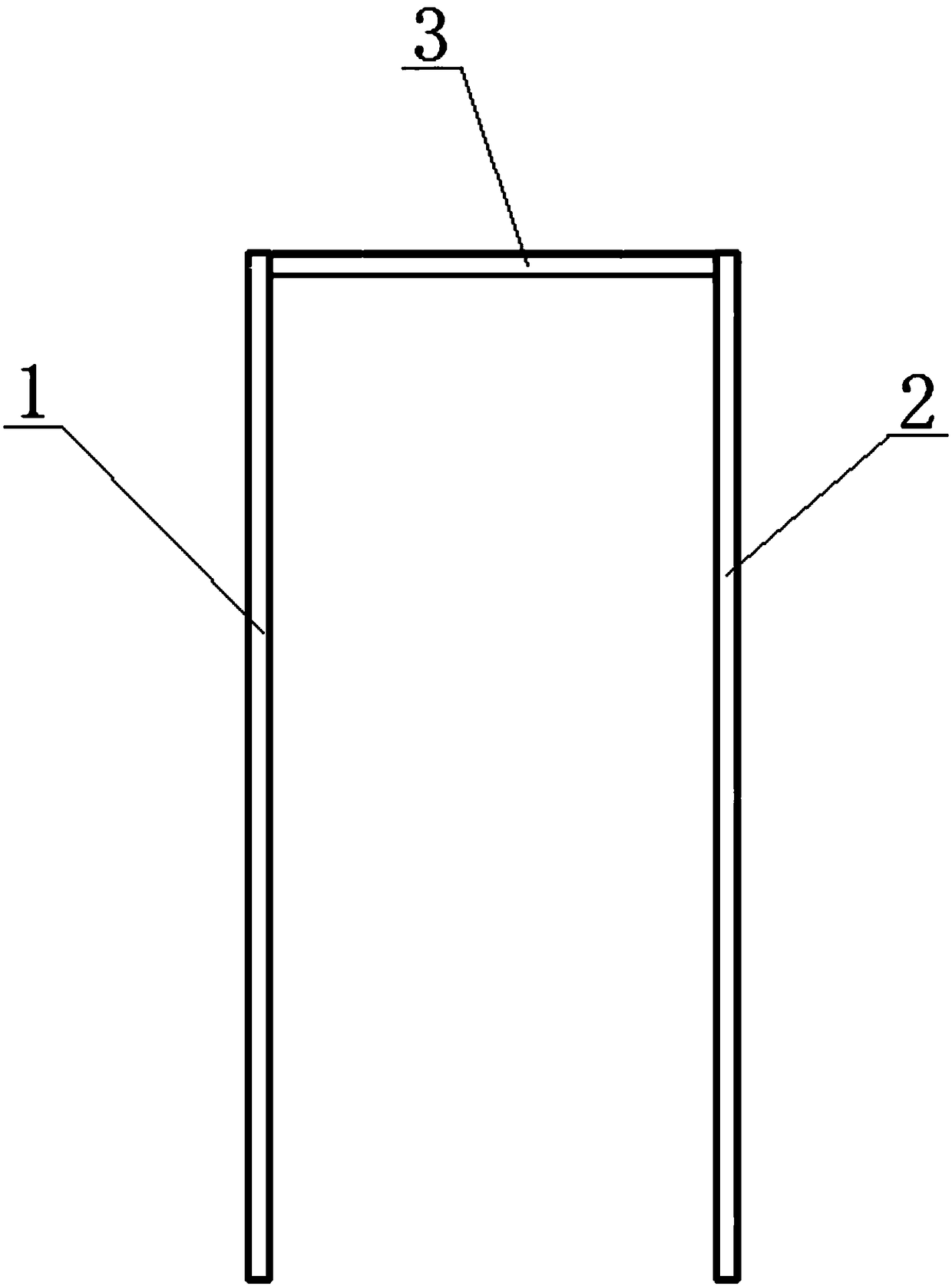

[0031] The present invention is composed of a hinge frame (1), a lock frame (2) and an upper frame (3).

[0032] figure 1 Shown is the structural representation of the present invention. Wherein, 1 is a hinge frame, 2 is a lock frame, and 3 is an upper frame.

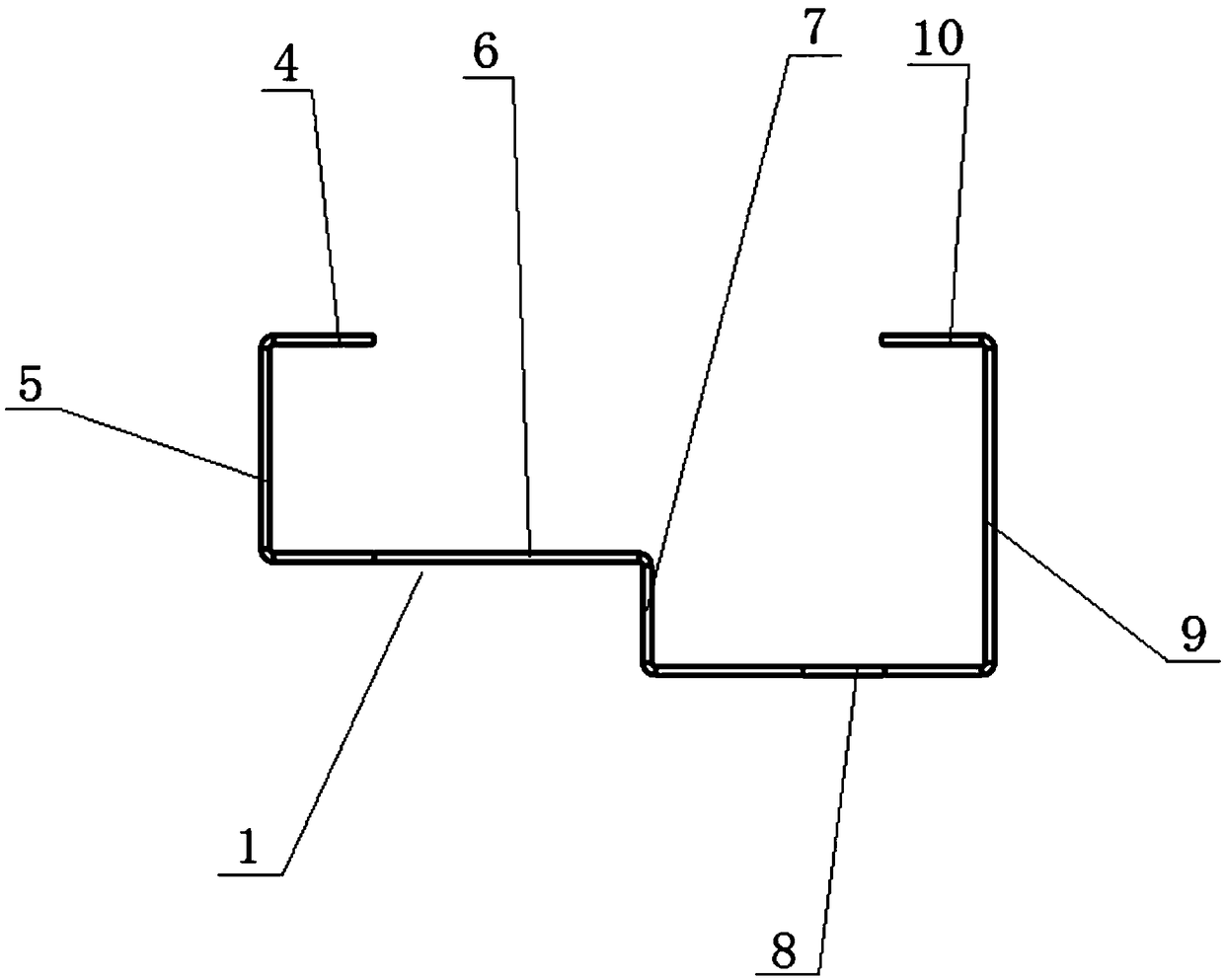

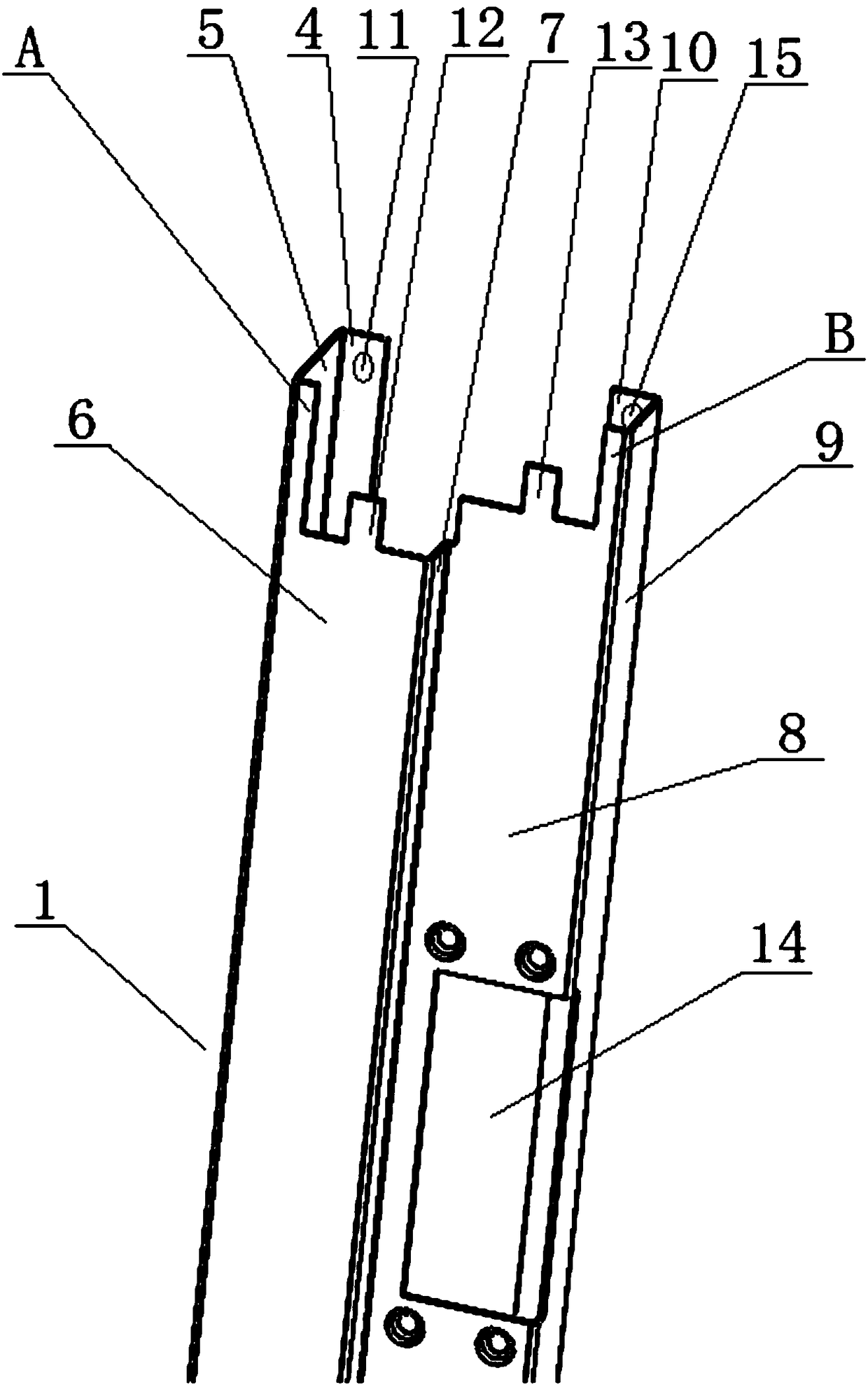

[0033] figure 2 and image 3Shown is a schematic structural view of the hinge frame (1) in the present invention. The hinge frame (1) is composed of a wall decoration surface (4), a lace decoration surface (5), a wall thickness decoration surface (6), a rubber strip installation surface (7), a hinge installation surface (8), and a step decoration surface (9) The decorative surface against the wall (10) is composed of a splicing screw fixing hole (11) at the upper end of the decorative surface against the wall (4), and a card position (A ) and mortise and tenon buckle (12), the top of the hinge installation surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com