Insulating flame-retardant bus duct and preparation method thereof

A technology of busway and busway, which is applied in the direction of cooling busway device and fully enclosed busway device, etc., which can solve the problems of inconvenient handling, poor fireproof performance and loss of busway, and achieve the effect of simple structure, easy disassembly and maintenance, and easy drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

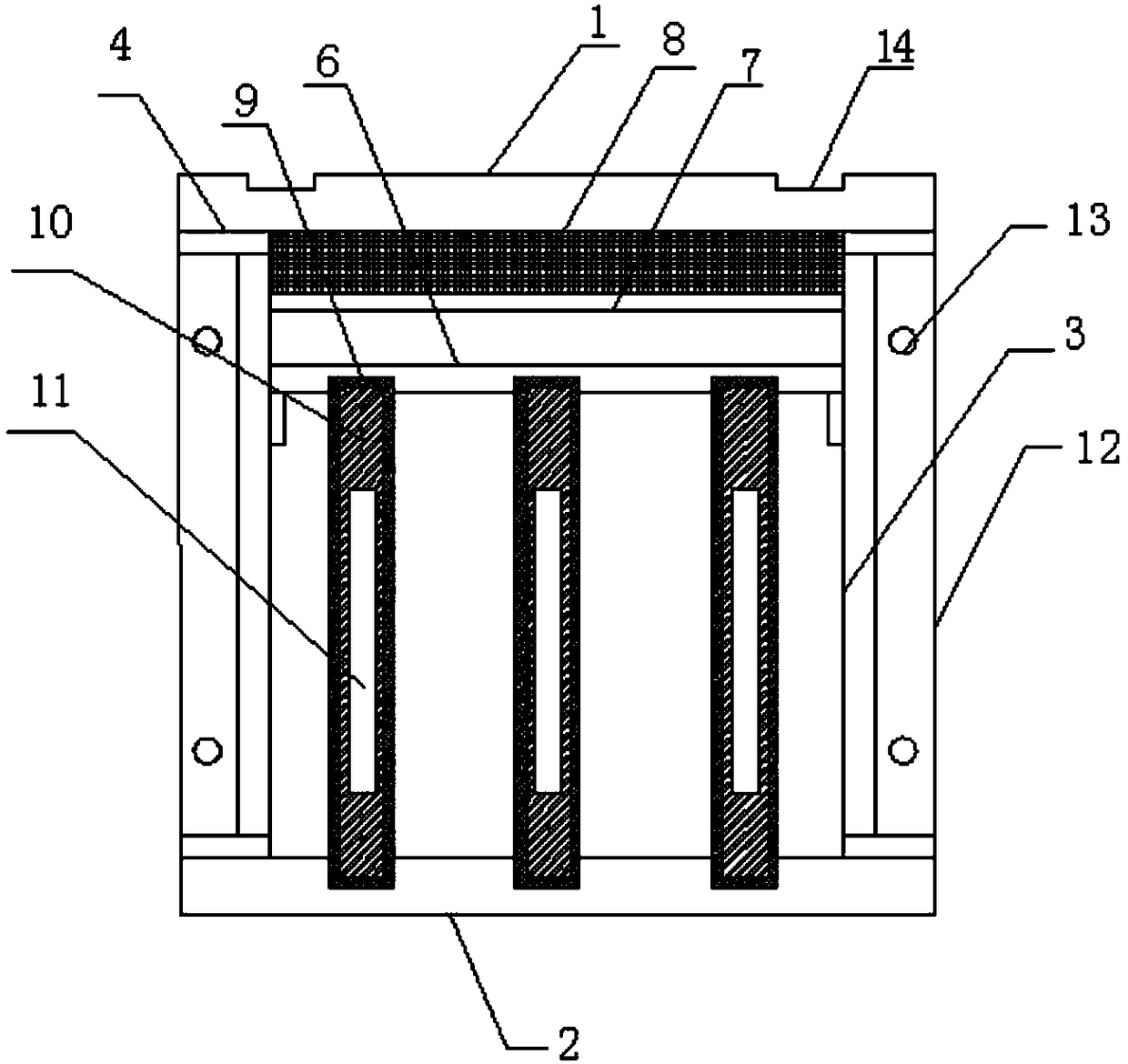

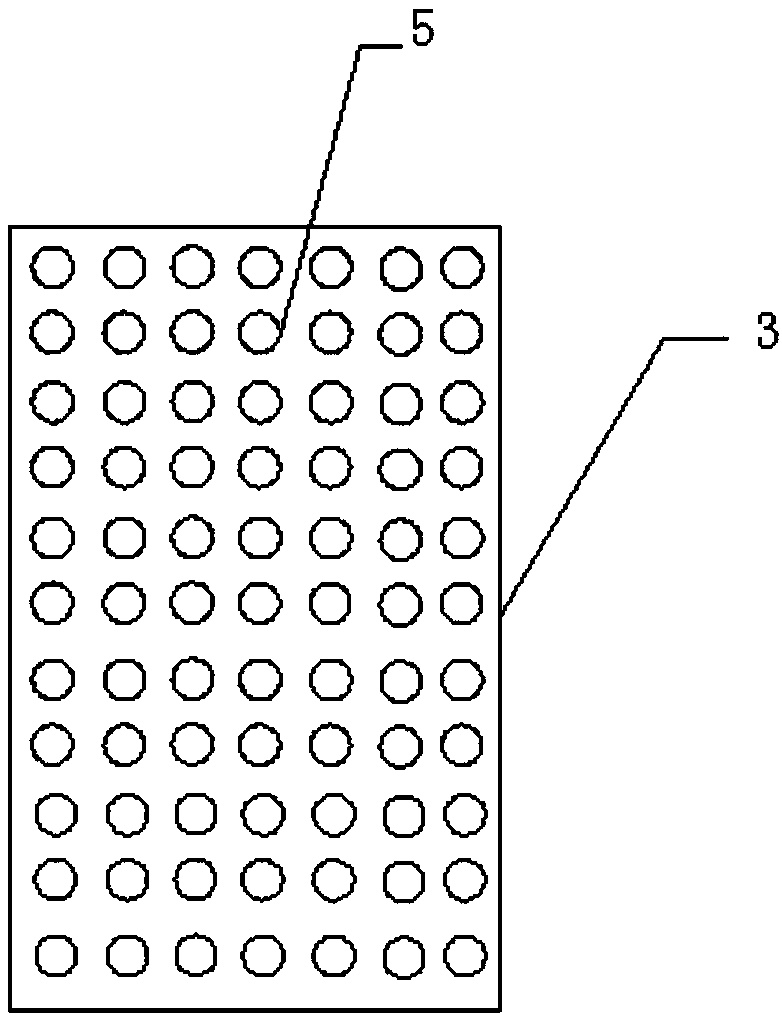

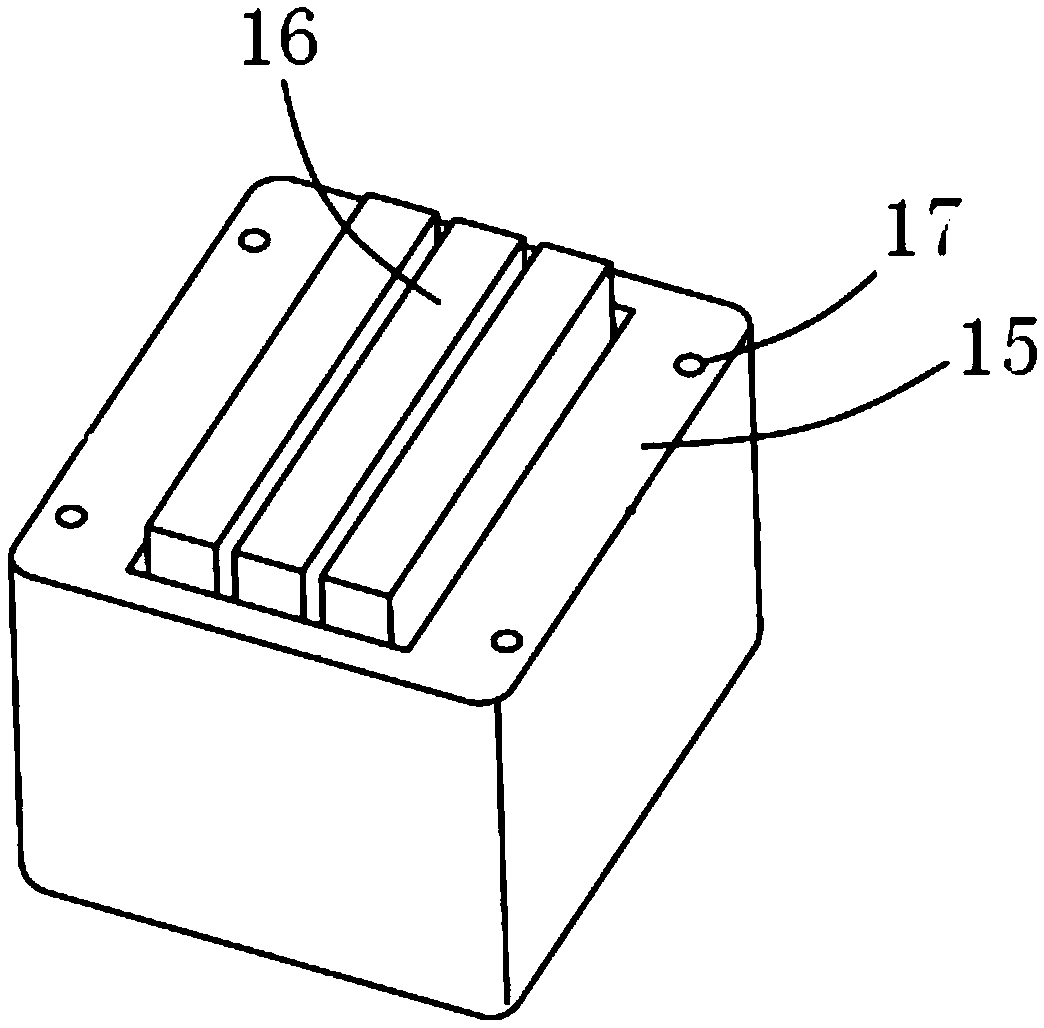

[0026] This embodiment provides an insulated and flame-retardant bus duct, the structure of which is as follows Figure 1-3 As shown, including the busway body and the busbar fixing protection device, the outside of the entire busway body is coated with a flame-retardant fireproof layer. The busway body is a frame structure composed of an upper cover plate 1, a bottom plate 2 and a side plate 3. Both sides of the top of the plate 1 are provided with drainage grooves 14, and the upper and lower ends of the side plate 3 are provided with fixed connecting plates 4, and the fixed connecting plates 4 at the upper and lower ends of the side plate 3 are respectively fixedly connected with the upper cover plate 1 and the bottom plate 2 by screws, and The side plate 3 is provided with heat dissipation holes 5, and the two ends of the side plate are respectively provided with a splicing plate 12, and the splicing plate is fixed on the two ends of the side plate by screws, and two fixing ...

Embodiment 2

[0036] This embodiment provides an insulated and flame-retardant bus duct, the structure of which is as follows Figure 1-3 As shown, including the busway body and the busbar fixing protection device, the outside of the entire busway body is coated with a flame-retardant fireproof layer. The busway body is a frame structure composed of an upper cover plate 1, a bottom plate 2 and a side plate 3. Both sides of the top of the plate 1 are provided with drainage grooves 14, and the upper and lower ends of the side plate 3 are provided with fixed connecting plates 4, and the fixed connecting plates 4 at the upper and lower ends of the side plate 3 are respectively fixedly connected with the upper cover plate 1 and the bottom plate 2 by screws, and The side plate 3 is provided with heat dissipation holes 5, and the two ends of the side plate are respectively provided with a splicing plate 12, and the splicing plate is fixed on the two ends of the side plate by screws, and two fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com