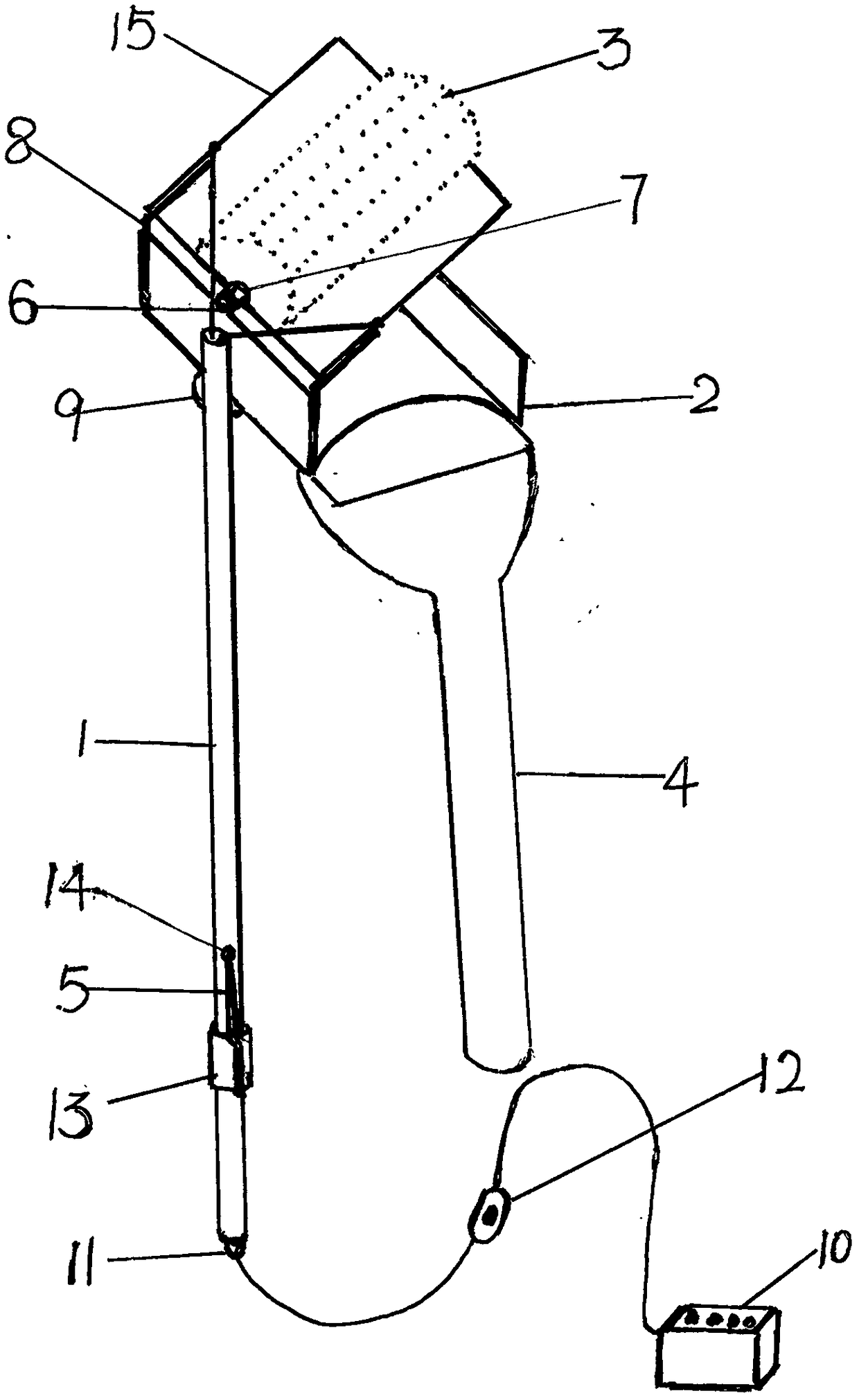

Ginkgo biloba leaf harvester

A collector and ginkgo leaf technology, applied in the field of economic plants, can solve the problems of no special tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Reference attached figure 1 , The long rod 1 is made of an aluminum alloy tube with a diameter of 4 cm and a length of 3 meters. The circular hole 14 is 1 meter from the lower end and has a diameter of 1 cm. The plate groove 2 is 1 mm thick, the groove depth is 8 cm, the bottom surface is 30×30 cm, the rear end arc depth is 10 cm, and the inner middle part is fixed to the upper part of the long rod 1 by 5 cm. The roller barrel 6 is a diameter of 4 cm, a length of 32 cm, and a middle part of 26 cm. There are 6-10 rows of elastic rubber-plastic round wires with a distance of 1 cm and a thickness of 1 mm and a length of 10 cm. The steel wire frame 15 is made of a steel wire with a diameter of 2 mm into a 29X29 cm square frame, and the circle holes 7 above the middle of both sides have an inner diameter of 4 cm. The elastic steel strip 8 has a thickness of 1 mm and a width of 5 mm. Two right-angled sides are each 8 cm long, and are fixed to the inner groove of the plate gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com