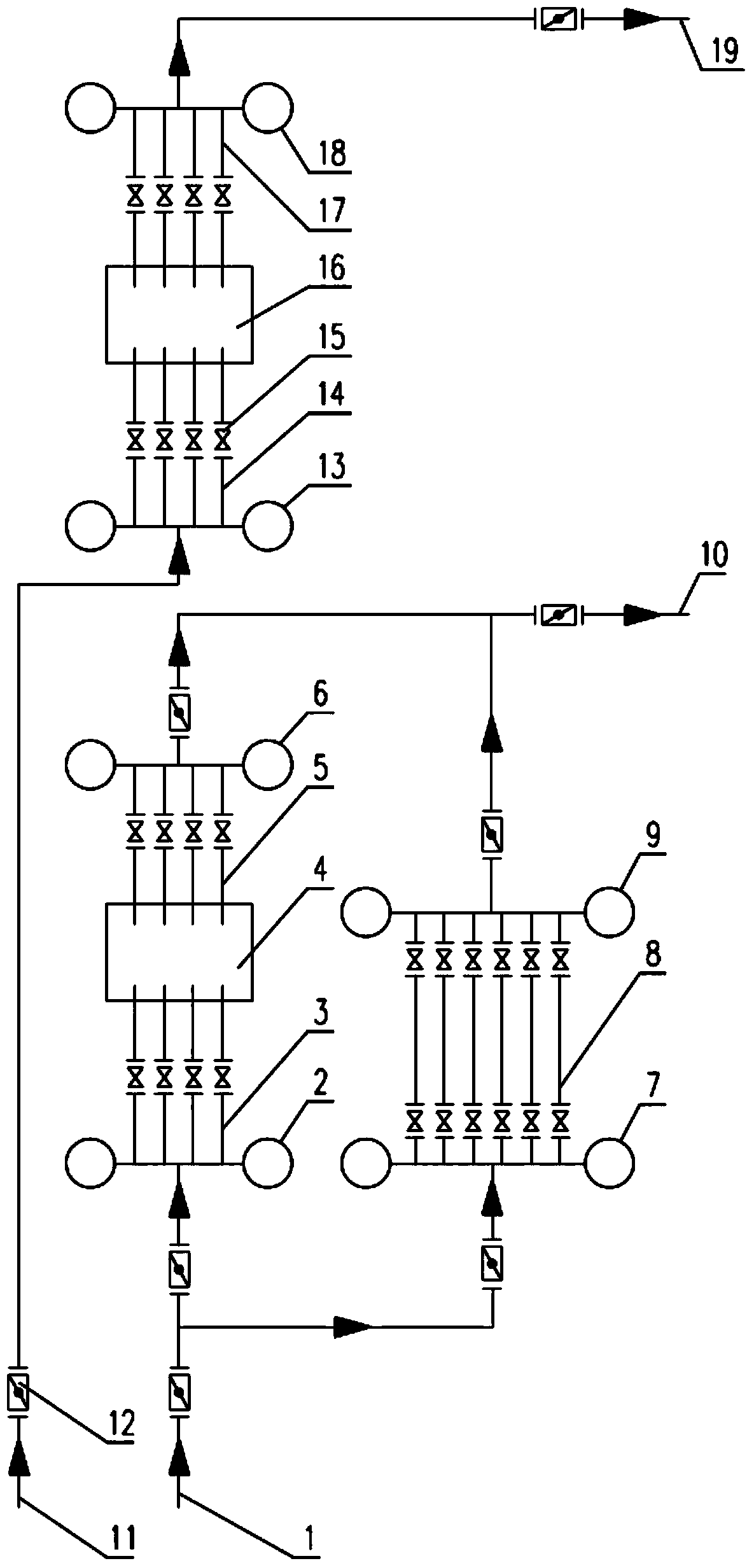

Sectional soft water closed circulation cooling system of blast furnace body

A soft water sealing and segmented technology, applied in the direction of cooling devices, etc., can solve the problems affecting the stable operation of the cooling system, inconsistent distribution of cooling equipment series pipelines, affecting the water consumption of cooling equipment in the lower area of the blast furnace, etc., to prolong the service life, Improve the effect of the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] like figure 1 As shown, the sectional soft water cooling system for the blast furnace body of the present invention is divided into two parts: the lower soft water closed circulation cooling system and the upper soft water closed circulation cooling system. Among them, the working process of the lower soft water closed circulation cooling system: the cooling water enters the water supply ring pipe 2 of the lower cooling equipment and the water supply ring pipe 7 of the furnace bottom water cooling pipe from the lower soft water supply main pipe 1, and the lower cooling equipment 4 and the furnace bottom water cooling pipe 8 respectively Cooling, after cooling, the return water ring pipe 6 of the lower cooling equipment and the return water ring pipe 9 of the furnace bottom water cooling pipe respectively enter the lower soft water return water main pipe 10 and return to the pump room, and then send it to the pump group for circulation after heat exchange and cooling by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com