Glue diluting machine for manufacturing electronic components

A technology of electronic components and glue, which is applied in the field of diluters, can solve the problems of manpower and time, uneven mixing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

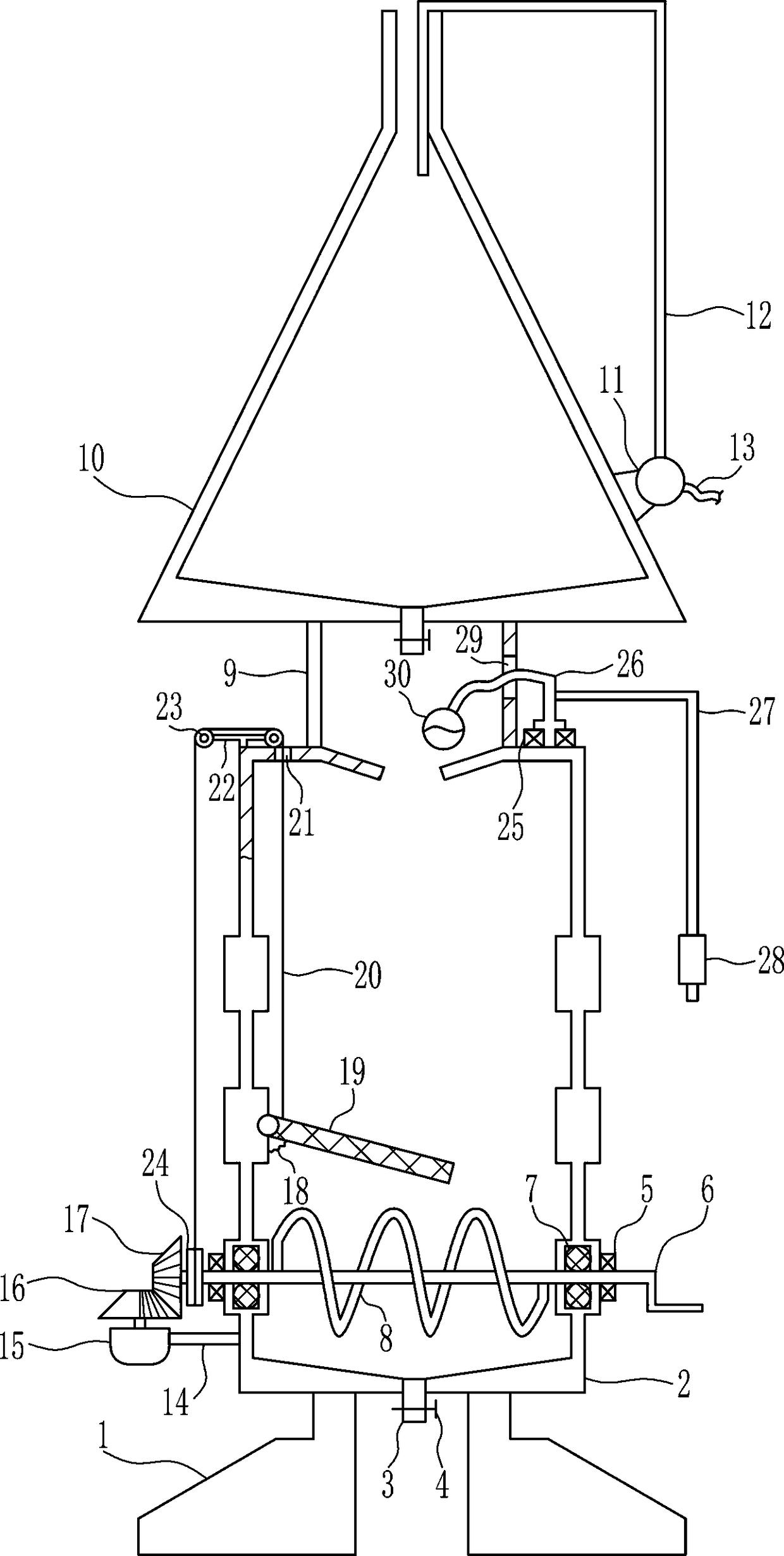

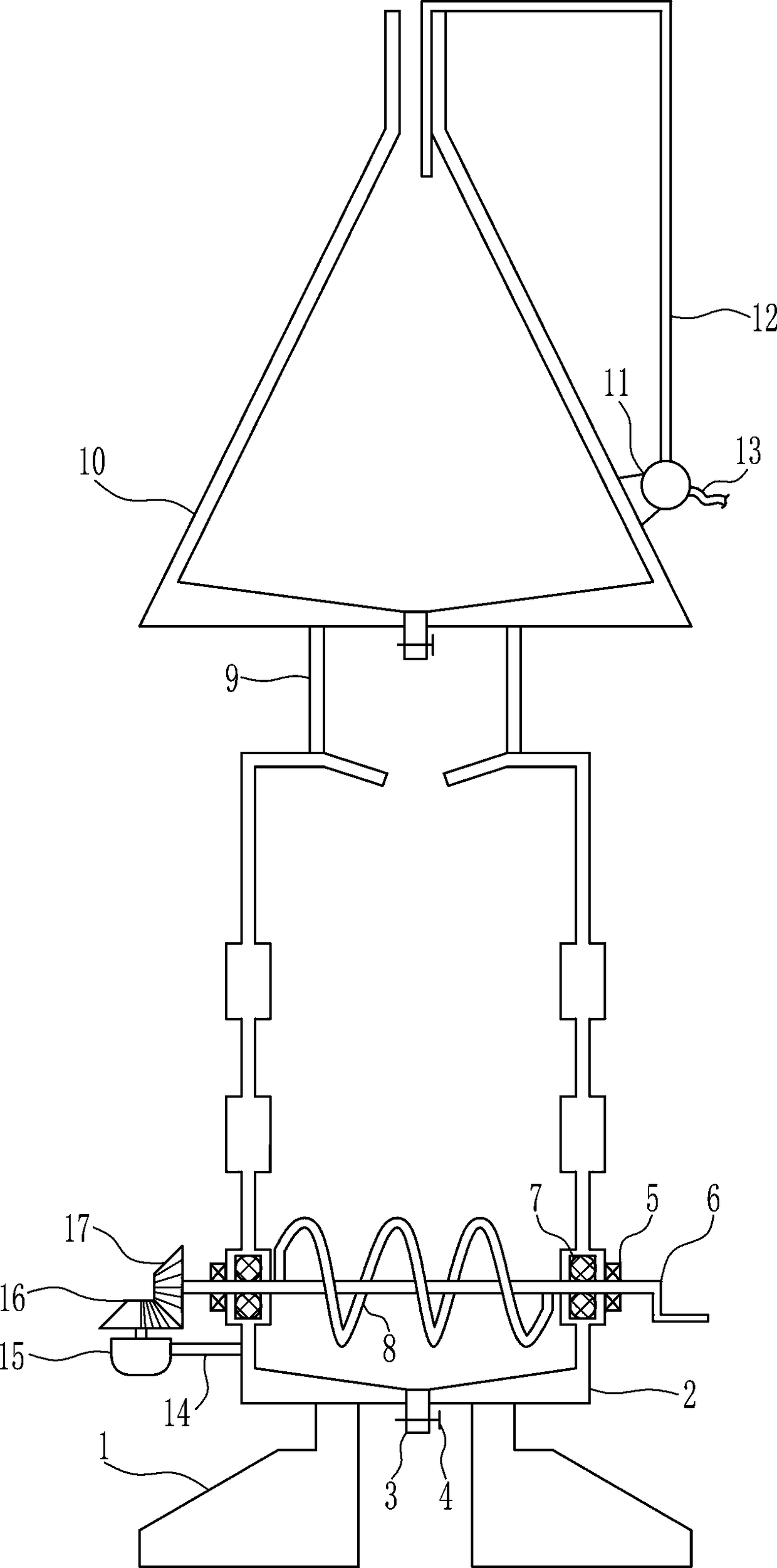

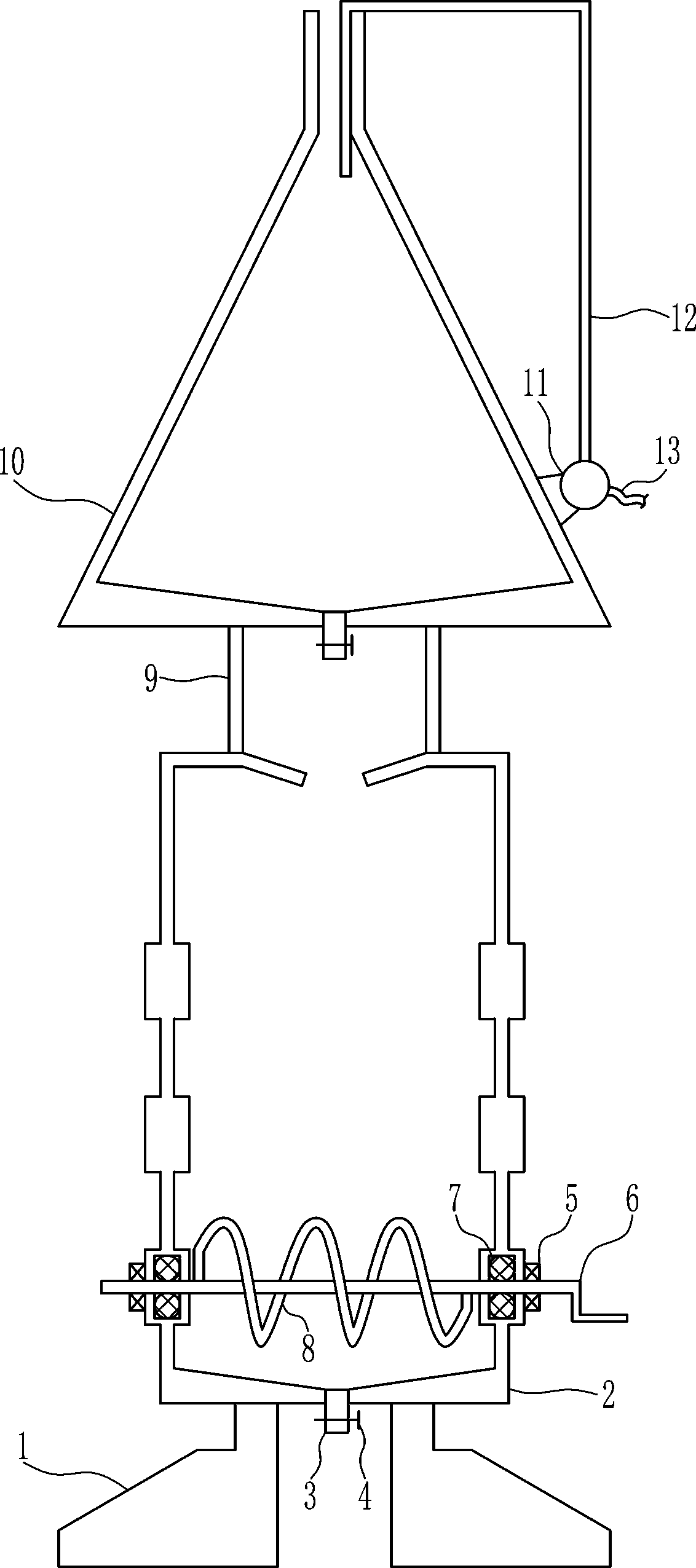

[0023] A kind of glue diluting machine for the manufacture of electronic components, such as Figure 1-5 As shown, it includes support seat 1, dilution box 2, discharge pipe 3, valve 4, first bearing seat 5, first rotating rod 6, sealing ring 7, screw rod 8, support rod 9, box body 10, pumping Liquid pump 11, feed pipe 12 and hose 13, the left and right sides of the lower side of the dilution tank 2 are equipped with support bases 1, the lower parts of the left and right walls of the dilution tank 2 are equipped with the first bearing seat 5, and the left and right sides of the first bearing seat 5 are installed. The interference connection of a bearing seat 5 is connected with the first rotating rod 6, and the left and right parts of the first rotating rod 6 are covered with sealing rings 7. Connected with a screw rod 8, the screw rod 8 is located in the dilution box 2, the left and right sides of the upper side of the dilution box 2 are fixedly connected with a support rod 9...

Embodiment 2

[0025] A kind of glue diluting machine for the manufacture of electronic components, such as Figure 1-5 As shown, it includes support seat 1, dilution box 2, discharge pipe 3, valve 4, first bearing seat 5, first rotating rod 6, sealing ring 7, screw rod 8, support rod 9, box body 10, pumping Liquid pump 11, feed pipe 12 and hose 13, the left and right sides of the lower side of the dilution tank 2 are equipped with support bases 1, the lower parts of the left and right walls of the dilution tank 2 are equipped with the first bearing seat 5, and the left and right sides of the first bearing seat 5 are installed. The interference connection of a bearing seat 5 is connected with the first rotating rod 6, and the left and right parts of the first rotating rod 6 are covered with sealing rings 7. Connected with a screw rod 8, the screw rod 8 is located in the dilution box 2, the left and right sides of the upper side of the dilution box 2 are fixedly connected with a support rod 9...

Embodiment 3

[0028]A kind of glue diluting machine for the manufacture of electronic components, such as Figure 1-5 As shown, it includes support seat 1, dilution box 2, discharge pipe 3, valve 4, first bearing seat 5, first rotating rod 6, sealing ring 7, screw rod 8, support rod 9, box body 10, pumping Liquid pump 11, feed pipe 12 and hose 13, the left and right sides of the lower side of the dilution tank 2 are equipped with support bases 1, the lower parts of the left and right walls of the dilution tank 2 are equipped with the first bearing seat 5, and the left and right sides of the first bearing seat 5 are installed. The interference connection of a bearing seat 5 is connected with the first rotating rod 6, and the left and right parts of the first rotating rod 6 are covered with sealing rings 7. Connected with a screw rod 8, the screw rod 8 is located in the dilution box 2, the left and right sides of the upper side of the dilution box 2 are fixedly connected with a support rod 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com