Axial tightening clamp for turbine housing

A turbine shell and axial technology, which is applied in the field of axial tightening fixtures for turbine shells, can solve the problems that it is impossible to judge whether the positioning surface of the turbine shell parts is in place, the lathe fixture has no positioning and tightening function, and the uniformity of processing and clamping cannot be guaranteed. , to achieve the effect of ensuring the repeatability of machining, convenient and quick adjustment, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

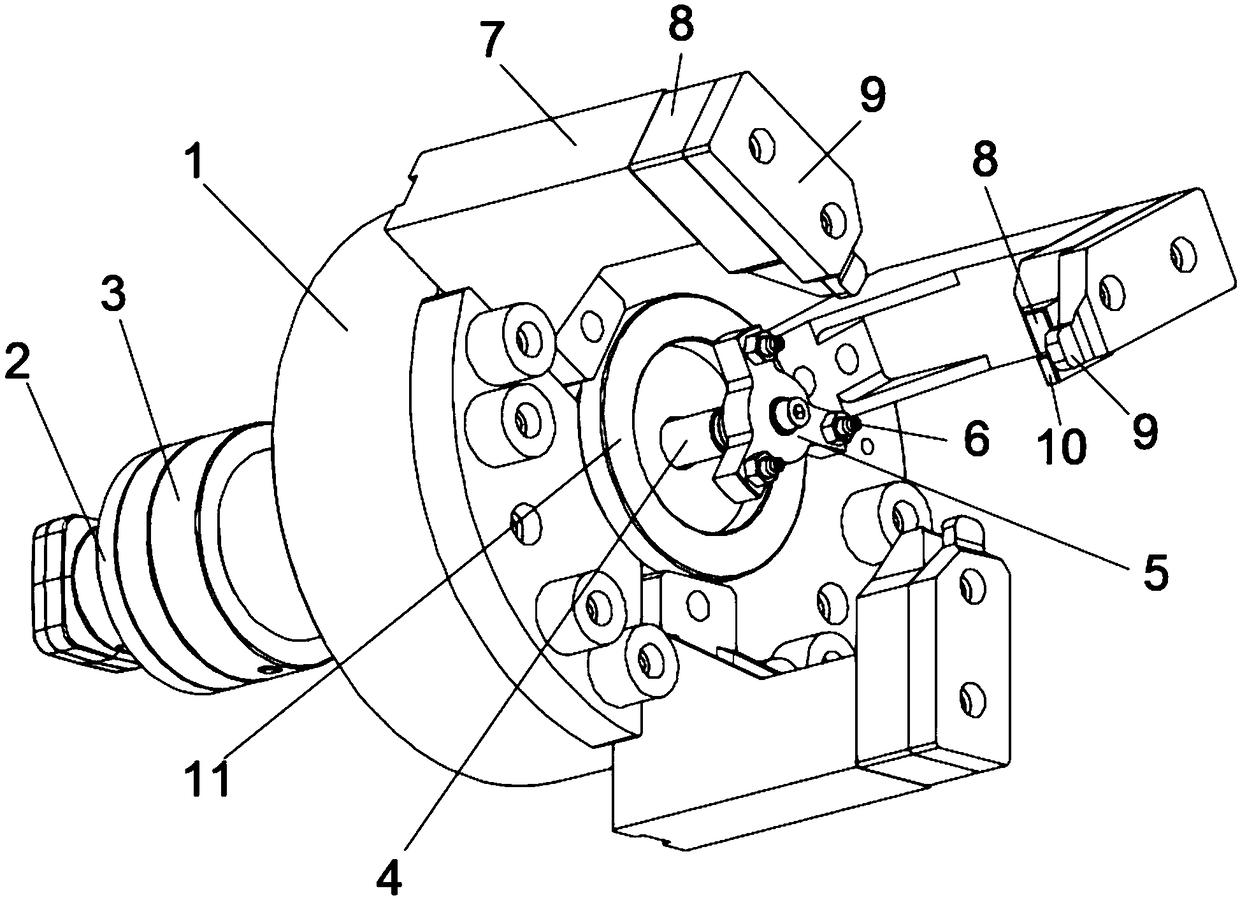

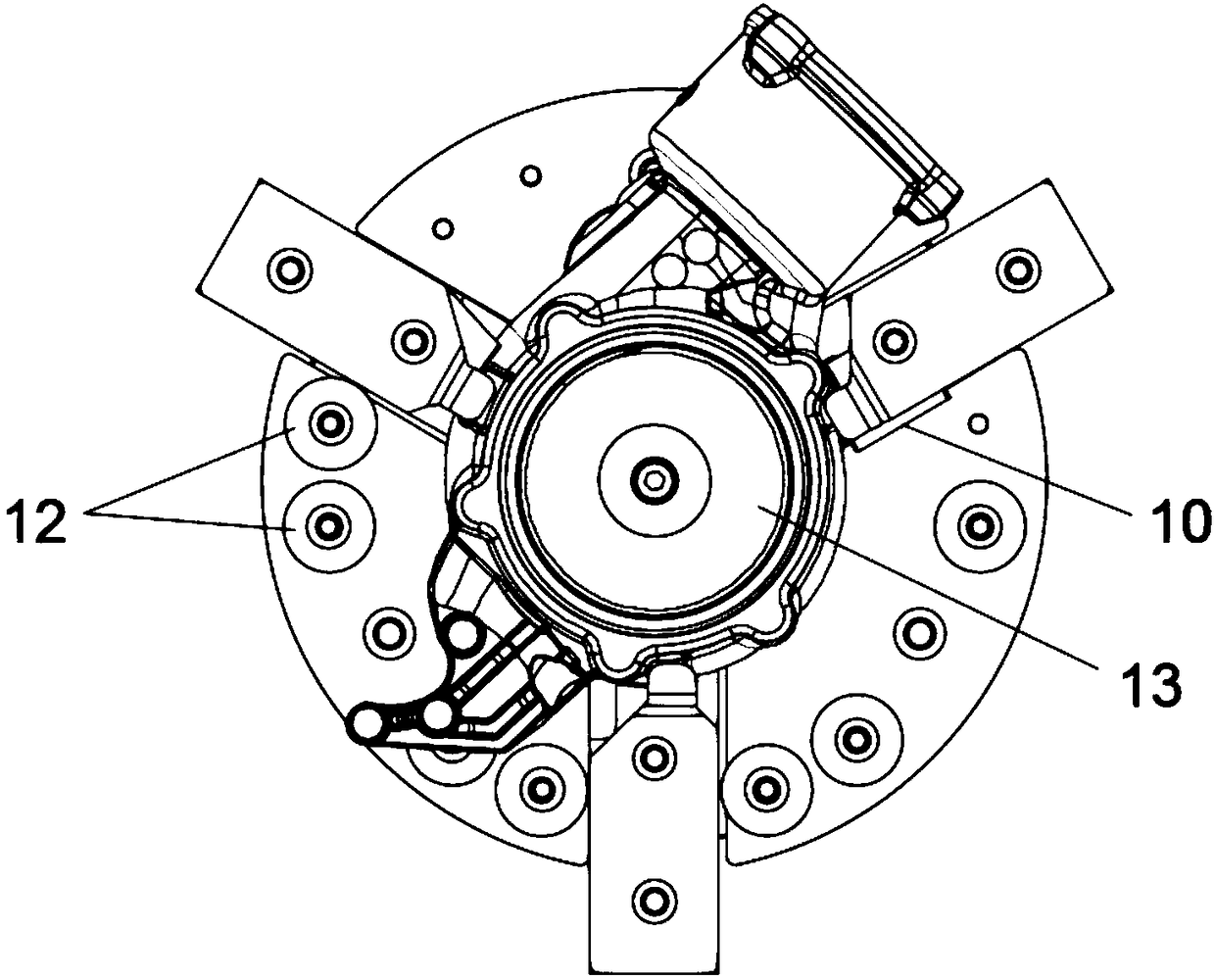

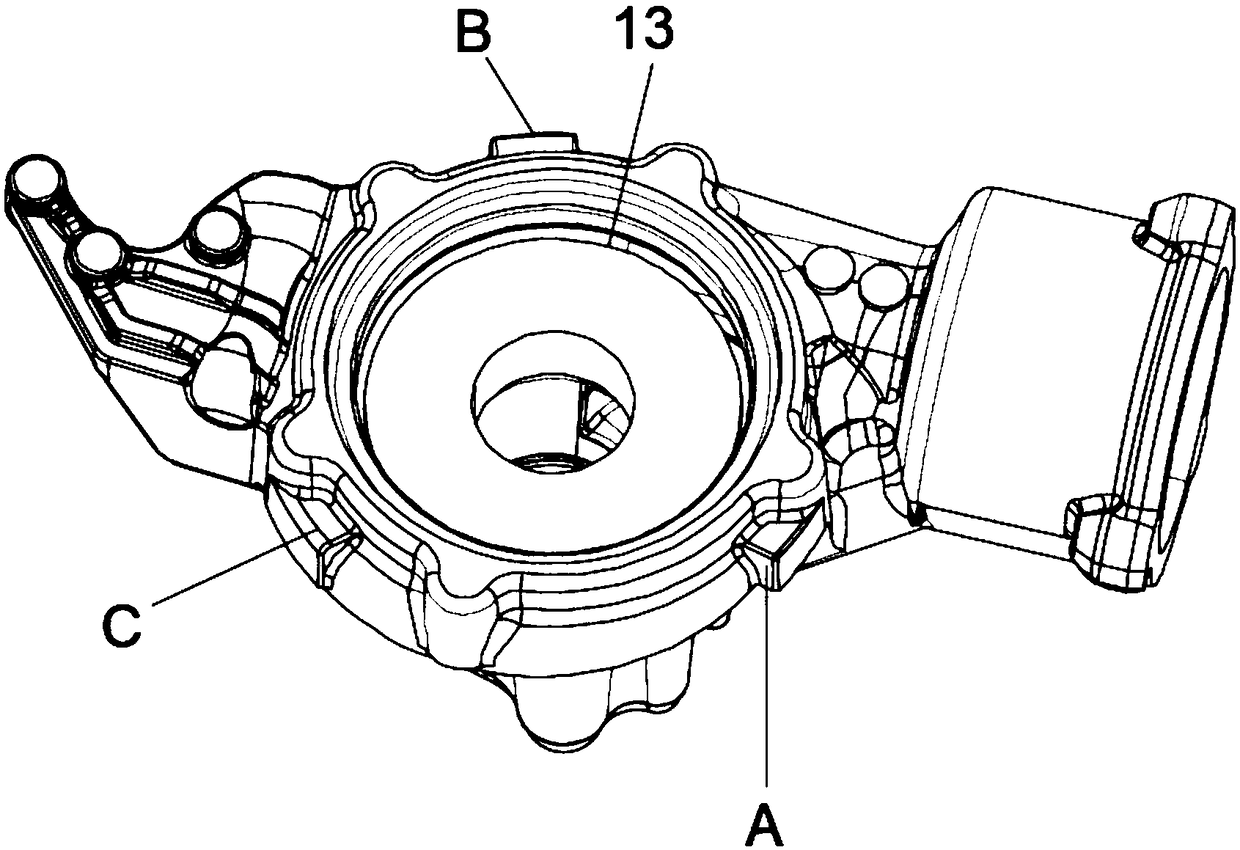

[0016] Such as figure 1 with figure 2 As shown, this embodiment provides a turbine shell axial clamping fixture, which includes a three-jaw chuck 1; the front end of the three-jaw chuck 1 is provided with three movable jaws 7; The front end is provided with a holding block 8; the front side of the holding block 8 is provided with a front limiting block 9; the side of the holding block 8 on one of the movable claws 7 is provided with a rotation limiting block 10; the three The middle position of the jaw chuck 1 is provided with a hydraulic rod 4; the front end of the hydraulic rod 4 is provided with a clamping block 5, and the clamping block 5 is provided with a top 6; the rear of the three-jaw chuck 1 is provided with The rotary cylinder 2 and the hydraulic cylinder for driving the hydraulic rod; the rotary cylinder 2 and the hydraulic cylinder are connected through the oil separator 3; the hydraulic cylinder is supplied with oil through the oil separator 3; the hydraulic r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com