Rail vehicle lifting method, coupler mounting seat for implementation of rail vehicle lifting method and rail vehicle

A coupler mounting seat and rail vehicle technology, applied in the field of rail vehicles, can solve the problems of easily damaged vehicle structure, no reliable fixed point, displacement of four lifting points, etc., and achieve increased vehicle cost, simple and convenient operation, and stable lifting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

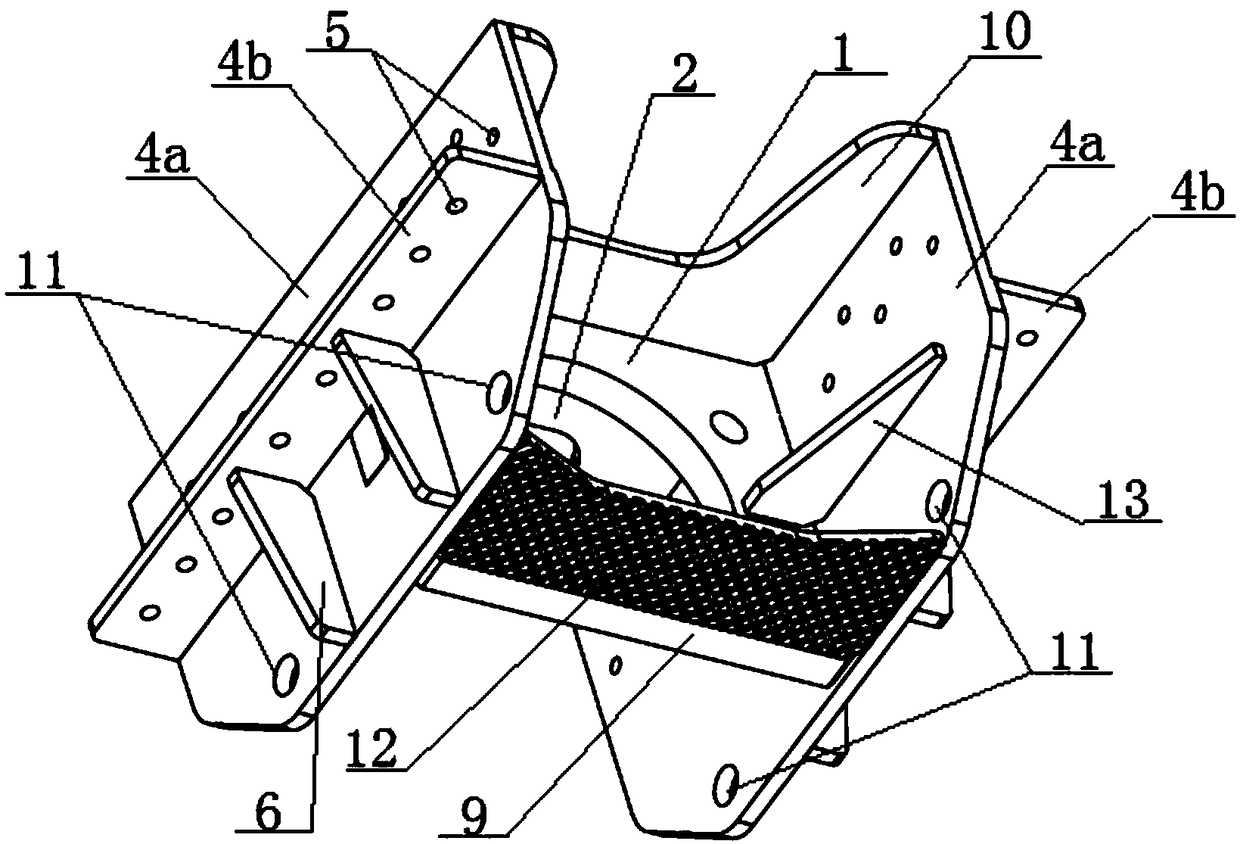

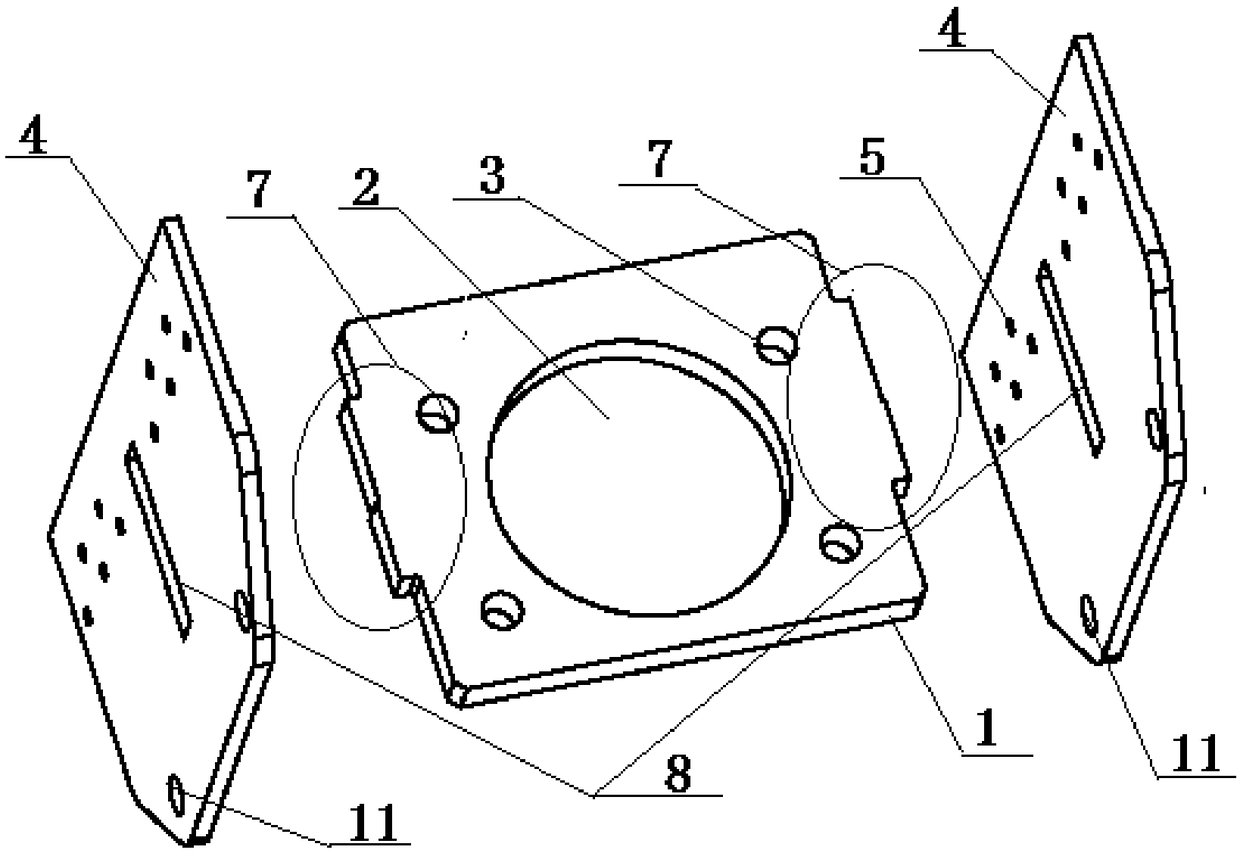

[0027] Such as figure 1 and figure 2 As shown, a coupler mounting seat provided by the present invention is fixedly installed on the draw beam (not shown in the figure) at the front part of the vehicle body underframe, and the coupler mounting seat is installed between the two draw beams. A coupler mounting seat is respectively installed at the front and rear ends of the car body.

[0028] The coupler mounting seat includes a coupler mounting plate 1, the setting direction of the coupler mounting plate 1 is perpendicular to the coupler, and the center of the coupler mounting plate 1 has an opening 2 for passing through the coupler (not shown in the figure). Four installation holes 3 are arranged around the opening 2 in the center, and the installation holes 3 are fixedly connected with the coupler by bolts.

[0029] A vertical plate 4 is respectively installed on both sides of the coupler mounting plate 1, and the two vertical plates 4 are perpendicular to the coupler mount...

Embodiment 2

[0043] This embodiment provides a method for lifting a rail vehicle, which is used to hoist the vehicle body to a required position when the vehicle body needs to be transported or transferred to another work station, such as a vehicle or ship for transporting the vehicle body, Or wait on the station that needs to be overhauled.

[0044] When lifting the car, the bearing part (not shown in the figure) used for lifting the car is leaned against and supported from below on the lifting floor 9 of the coupler mounting seat as described in Embodiment 1, and the couplers at the front and rear ends of the car body are installed. Each bearing is installed under the seat, and the bearing is connected with the lifting device. The lifting device can be a crane for hoisting. The two sides of each bearing are respectively connected with the crane through the straps. Lift and lift the car body as a whole to the required position.

[0045] After hoisting the car body to the transport vehicl...

Embodiment 3

[0048] This embodiment provides a rail vehicle, including a bogie, a car body, etc. The car body is composed of sides, end walls, roof and an underframe, and traction beams are installed at the front and rear ends of the underframe. The longitudinal direction of the body is provided with two parallel, as described in the first embodiment, the coupler mount is installed between the two draw beams, and the two sides of the coupler mount are respectively fixedly connected with the draw beams on both sides by rivets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com