Double-hook crane slewing trolley

A technology of cranes and double hooks, applied in the direction of load block, spring mechanism, load hanging components, etc., can solve the problems of inability to rotate, inconvenient use, limited use range, etc., to prolong life, use flexibly, weaken The effect of lateral stress influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

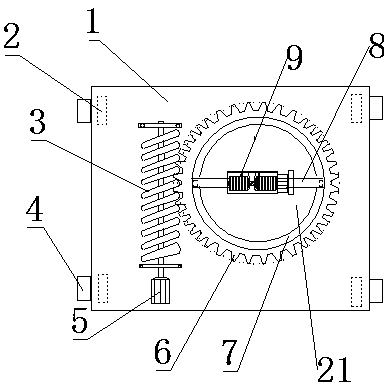

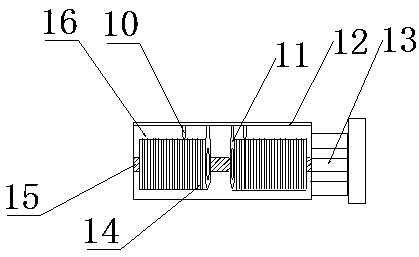

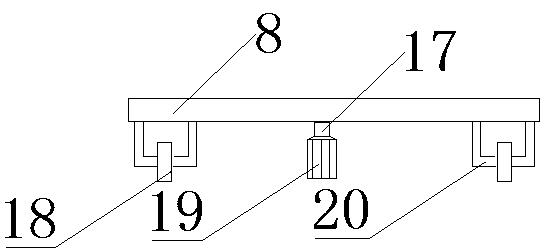

[0015] Such as Figure 1-3 As shown, the purpose of the present invention is achieved in this way: a double-hook crane slewing trolley, which includes a slewing trolley body 1, the four corners of the slewing trolley body 1 are provided with walking wheels 2, and the walking The outer sides of the wheels 2 are provided with elastic buffer pads 4, the left side of the revolving trolley body 1 is provided with a worm 3, one end of the worm 3 is connected with a frequency conversion motor 5, and the right side of the worm 3 is provided There is a turntable 21, the outer side of the turntable 21 is provided with a ring gear 6, the worm 3 is meshed with the ring gear 6, the inner side of the ring gear 6 is provided with a rotating ring 7, and the rotating ring 7 is A support plate 8 is provided, and a lifting mechanism 9 is arranged above the support plate 8, and the lifting mechanism 9 is composed of a reel 16 and a motor 13, and a fixed rod 12 is arranged above the reel 16 , the...

Embodiment 2

[0018] Such as Figure 1-3 As shown, the purpose of the present invention is achieved in this way: a double-hook crane slewing trolley, which includes a slewing trolley body 1, the four corners of the slewing trolley body 1 are provided with walking wheels 2, and the walking The outer sides of the wheels 2 are provided with elastic buffer pads 4, the left side of the revolving trolley body 1 is provided with a worm 3, one end of the worm 3 is connected with a frequency conversion motor 5, and the right side of the worm 3 is provided There is a turntable 21, the outer side of the turntable 21 is provided with a ring gear 6, the worm 3 is meshed with the ring gear 6, the inner side of the ring gear 6 is provided with a rotating ring 7, and the rotating ring 7 is A support plate 8 is provided, and a lifting mechanism 9 is arranged above the support plate 8, and the lifting mechanism 9 is composed of a reel 16 and a motor 13, and a fixed rod 12 is arranged above the reel 16 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com