Upper cover closure cushioning device and washing machine

A technology of buffer device and magnetic parts, which is applied in the field of washing machines, can solve the problems of fast falling speed of the upper cover, achieve the effect of simple structure and avoid bump damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

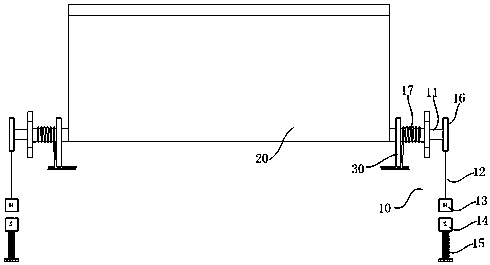

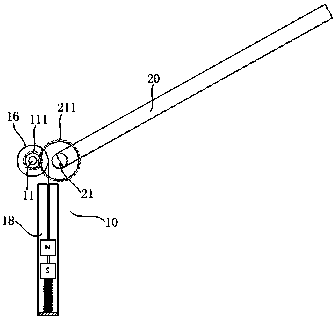

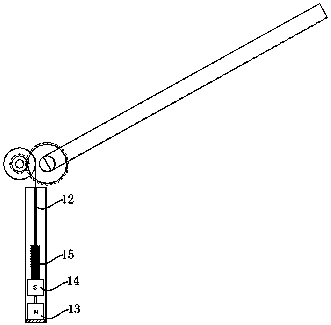

[0026] This embodiment proposes a top cover closing buffer device, which can be applied to any household appliance with the top open. It includes a transmission shaft 11, a cable 12 and an elastic structure, wherein the transmission shaft 11 passes through the The rotating shaft 21 rotates to realize the transmission connection with the rotating shaft 21 . The two ends of the cable 12 are respectively the trailing end and the load-bearing end, and the trailing end of the cable 12 is fixedly connected with the transmission shaft 11 for being wound up on the transmission shaft 11 when the upper cover 20 falls. The elastic structure is fixedly connected to the load-bearing end of the flexible cable 12, and is used to generate gradually increasing tensile resistance when the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com